موازن لخط النقل

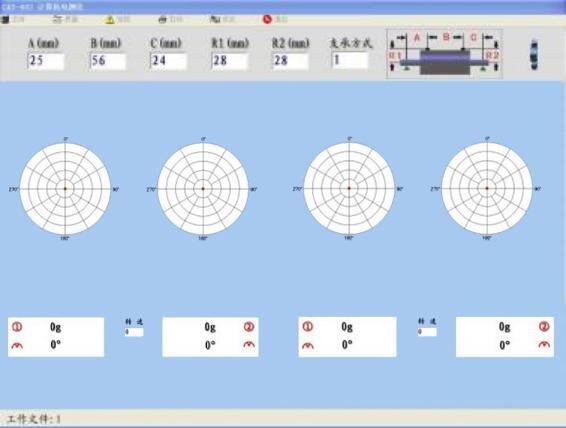

إن مُوازنِ الناقل هو أداة تشخيصية وصيانة أساسية مصممة لتحديد وتصحيح حالات عدم التوازن في عمود نقل السيارة، والعمود الدافع، ومكونات دوارة أخرى. تستخدم هذه المعدات المتقدمة تقنية استشعار متطورة لقياس مستويات الاهتزاز وتحديد مواقع عدم التوازن بدقة استثنائية. تعمل أداة موازن الناقل من خلال قياسات إلكترونية عالية الدقة، ويمكنها اكتشاف التشوهات عند سرعات وأحمال مختلفة، مما يضمن تحليلًا شاملاً لمنظومة الناقل بأكملها. كما تحتوي الأداة على قدرات معالجة رقمية لتحليل أنماط الاهتزاز المعقدة وتوفير ملاحظات فورية لإجراء تعديلات موازنة دقيقة. تتميز موازنات الناقل الحديثة بواجهات سهلة الاستخدام تعرض معلومات تشخيصية مفصلة، مما يمكّن الفنيين من تحديد المشكلات بسرعة وتنفيذ الإجراءات التصحيحية. تعتبر هذه الآلات ذات قيمة خاصة في Workshops السيارات، ومرافق صيانة الشاحنات، والبيئات الصناعية حيث إن الحفاظ على أداء ناقل الأمثل أمر بالغ الأهمية لتشغيل المركبات وسلامتها. تتيح هذه التقنية إجراء عمليات موازنة ثابتة وديناميكية، مما يضمن تغطية كاملة لجميع السيناريوهات المحتملة بعدم التوازن. وبفضل قدرتها على التعامل مع أحجام وتكوينات مختلفة لأعمدة النقل، أصبحت هذه الآلات أدوات لا غنى عنها في صيانة المركبات الاحترافية.