Understanding the Fundamentals of Crankshaft Dynamics

The heart of any internal combustion engine lies in its crankshaft - a precision-engineered component that converts linear piston motion into rotational force. Crankshaft balancing plays a crucial role in ensuring optimal engine performance, longevity, and smooth operation. When a crankshaft isn't properly balanced, it can lead to excessive vibration, reduced power output, accelerated wear, and potentially catastrophic engine failure.

Whether you're rebuilding a classic car engine or maintaining a high-performance racing powerplant, mastering crankshaft balancing techniques is essential. This comprehensive guide will walk you through the intricate process of achieving perfect rotational harmony in your engine's most critical component.

Essential Equipment and Preparation

Professional Balancing Equipment

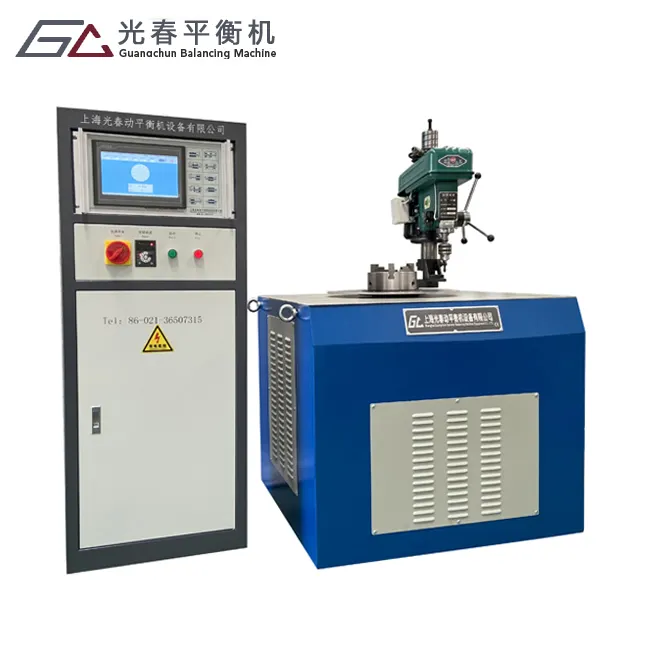

Successful crankshaft balancing requires specialized equipment that can measure even the slightest imbalances with extreme precision. A professional-grade balancing machine is the cornerstone of this process. These machines typically consist of precision rollers, sophisticated sensors, and a computer interface that provides detailed analysis of the crankshaft's rotating characteristics.

The most common types of balancing machines are hard-bearing and soft-bearing systems. Hard-bearing machines are typically more robust and better suited for heavy-duty applications, while soft-bearing systems offer enhanced sensitivity for precision work. Both types must be properly calibrated and maintained to ensure accurate results.

Measurement and Documentation Tools

Beyond the balancing machine itself, you'll need various measurement tools including micrometers, dial indicators, and precision scales. Digital calipers are essential for measuring journal diameters and checking tolerances. A comprehensive set of documentation tools, including worksheets and digital software, helps track measurements and calculations throughout the balancing process.

The Balancing Process Step by Step

Initial Inspection and Cleaning

Before beginning the actual balancing procedure, thoroughly clean the crankshaft using appropriate solvents and inspection techniques. Check for signs of wear, cracks, or damage that could affect the balancing process. Pay special attention to the main journals and rod journals, as these surfaces must be in excellent condition for accurate measurements.

Use magnetic particle inspection or dye penetrant testing to identify any hidden flaws that could compromise the crankshaft's integrity. Document all findings and address any issues before proceeding with the balancing operation.

Static Balancing Fundamentals

Static balancing represents the first phase of the process, where the crankshaft is checked for heavy spots while at rest. Place the crankshaft on precision V-blocks or specialized fixtures that allow free rotation. The heavy side will naturally rotate to the bottom position. This preliminary step helps identify major imbalances before moving to dynamic balancing.

Mark any obvious heavy spots and calculate the approximate weight that needs to be removed. Remember that static balancing alone is insufficient for modern engines operating at high RPMs - it's merely the foundation for the more complex dynamic balancing process.

Advanced Dynamic Balancing Techniques

Setting Up the Balancing Machine

Proper machine setup is critical for accurate dynamic balancing. Mount the crankshaft in the balancing machine using appropriate fixtures and supports. Ensure all mounting points are clean and properly aligned. The crankshaft must be able to rotate freely without any binding or resistance that could affect measurements.

Enter the correct specifications into the balancing machine's computer, including the crankshaft's weight, desired RPM for testing, and tolerance limits. These parameters will guide the balancing process and help achieve the desired results.

Material Removal Methods

Once imbalances are identified, material must be carefully removed from specific locations to achieve proper balance. This can be done through drilling, grinding, or milling, depending on the crankshaft design and material. The key is to remove material symmetrically and in a way that maintains the crankshaft's structural integrity.

Always start with conservative material removal and recheck the balance frequently. It's easier to remove more material if needed than to correct over-removal. Consider the effects of material removal on the crankshaft's strength and durability, particularly in high-stress applications.

Quality Control and Verification

Testing Procedures

After completing the initial balancing work, conduct thorough testing at various RPM ranges to verify the results. Modern balancing machines can simulate different operating speeds and load conditions, helping ensure the crankshaft will perform well under actual running conditions. Document all test results and compare them against manufacturer specifications or racing requirements.

Pay special attention to critical speeds where resonance might occur, as these can reveal balance issues that might not be apparent at other RPMs. Multiple test runs may be necessary to confirm consistency and stability of the balance work.

Final Inspection and Documentation

Perform a final inspection of all work performed, checking for any signs of stress risers or surface irregularities created during the balancing process. Measure and document all final dimensions and balance specifications for future reference. This documentation is particularly important for racing applications where regular inspection and maintenance are required.

Frequently Asked Questions

How often should a crankshaft be balanced?

A crankshaft typically needs balancing when it's new, after major engine work, or if vibration issues develop. High-performance engines may require more frequent balance checks, especially in racing applications where components are under extreme stress.

What are the signs of an unbalanced crankshaft?

Common indicators include excessive engine vibration, unusual bearing wear, reduced performance, and irregular oil consumption. You might also notice increased noise levels or vibration at specific RPM ranges.

Can I balance a crankshaft without specialized equipment?

While basic static balancing can be performed with precision V-blocks, professional dynamic balancing requires specialized equipment. For best results and engine longevity, crankshaft balancing should be performed by qualified professionals using proper equipment.

What tolerance levels are acceptable for crankshaft balancing?

Acceptable tolerance levels vary by application, but most street engines require balancing within 1-2 grams, while high-performance racing engines may need even tighter tolerances of 0.5 grams or less. Always consult manufacturer specifications for your specific application.