Understanding Propshaft Function and Balance Requirements

The Role of Propshafts in Vehicle Dynamics

The propshaft does something pretty important for how cars move around. It takes power from the engine and sends it out to the wheels so the car can actually drive forward. Without this component working right, the whole drivetrain gets messed up. When everything lines up properly, drivers notice better handling when taking corners and generally smoother operation overall. But if someone doesn't get the balance right on these shafts, bad things happen. The car starts shaking at certain speeds, people complain about uncomfortable rides, and eventually parts start breaking down because of all that stress. Mechanics always check these things first when customers bring in vehicles with strange vibration problems. Getting propshafts balanced correctly isn't just about making sure the car runs smoothly either it literally keeps everyone safe while they're on the road.

Principles of Rotational Balance in Drivelines

Getting rotational balance right matters a lot for how smoothly a vehicle's driveline works. When there's an imbalance, it usually comes down to uneven weight spread across the propshaft. People talk about dynamic balancing when they want to fix this issue, which helps vehicles perform better and last longer on the road. Looking at weight distribution isn't just about numbers though. Mechanics need to check out what materials went into making the propshaft and its overall design too. These factors really affect how efficient and durable the whole driveline system ends up being. Taking all this into account makes sure that the propshaft doesn't cause problems but actually supports good handling characteristics across different driving conditions.

Consequences of Imbalance Tolerance Exceedance

When imbalance goes beyond acceptable limits, it creates serious vibrations that gradually wear down drivetrain parts. We've seen plenty of cases where constant vibration damage leads to early failure of components such as universal joints and wheel bearings. Looking at actual numbers helps explain why routine maintenance matters so much when checking for balance issues. Regular inspections catch problems before they turn into expensive fixes and help keep those vital vehicle parts working longer. Vehicles stay safer and run better when we address imbalances early instead of waiting until something breaks down completely.

Vibration Patterns: Early Detection of Unbalanced Propshafts

Speed-Dependent Vibration Characteristics

Keeping track of how vibrations change with speed helps spot problems with unbalanced propshafts. When engine revolutions go up, those annoying shakes get worse too, so checking them at various speeds matters a lot. Looking at this kind of vibration pattern lets technicians catch small issues before they turn into big headaches down the road. With proper equipment like balancing machines on hand, mechanics can actually see where things are going wrong in the vibration profile. This gives real world information needed to keep vehicles running smoothly without unexpected breakdowns.

Auditory Cues: Knocking and Clunking Noises

Paying attention to strange sounds from the drivetrain, especially knocking or clunking noises when turning corners, helps spot problems with unbalanced propshafts. These kinds of noises usually mean there's some kind of issue lurking underneath, acting as red flags that something isn't quite right. When drivers catch these sounds early on, they get a chance to fix whatever imbalance exists before it turns into major mechanical trouble down the road. Regular drivers should keep their ears open for these telltale signs while driving around town. The sooner someone notices these odd noises, the better chance they have at avoiding expensive repair bills later on and keeping their car running smoothly for longer periods between maintenance checks.

Steering Wheel Feedback as Diagnostic Indicator

When something feels off through the steering wheel, it's often a sign that there's a problem with the propshaft balance. Most drivers will feel either vibrations coming through the wheel or some sort of instability when turning, which usually means there's an imbalance somewhere along the driveline. Looking at how the steering responds helps mechanics figure out exactly where these vibrations are coming from so they can fix whatever part needs attention. Research shows that keeping the driveline balanced makes a big difference in ride quality too. Nobody wants to deal with constant shaking while driving down the highway. The good news is that paying attention to what the steering wheel tells us speeds up diagnosis time and makes sure whatever fixes get done actually solve the real issue instead of just masking symptoms for a while.

Component Degradation from Imbalance Forces

Accelerated U-Joint and Bearing Failure

When there's imbalance in the forces acting on a driveline system, it takes a real toll on U-joints and bearings, causing them to wear out much faster than normal. The uneven stress distribution basically cuts down how long these parts last before they fail. Mechanics see this all the time in trucks that regularly operate over rough terrain where vibrations run rampant. By getting to grips with why these failures happen, technicians can create better maintenance schedules that keep drivelines running smoothly for longer periods. A well maintained driveline not only saves money on replacements but also prevents unexpected breakdowns that disrupt operations.

Transmission Damage Mechanisms

When propshafts get out of balance, they put way too much stress on the transmission which can really mess things up after some time driving around. Getting a handle on how this happens matters a lot if we want to avoid expensive fixes down the road and keep cars running longer than expected. There actually is a pretty strong connection between keeping those propshafts balanced properly and making sure transmissions last through many miles. Mechanics often measure this relationship during routine checks so they know when something needs attention before it turns into bigger problems for drivers everywhere.

Differential and Axle Load Implications

When there's too much imbalance force acting on a vehicle, it puts extra strain on the differentials and axles, often leading to early breakdowns of these important parts. The problem doesn't stop there either. What starts as simple imbalance can spread throughout the entire driveline system, affecting how well the car performs and even creating safety concerns. To avoid all this trouble, regular checks and proper balancing work wonders in preventing damage. Most mechanics recommend getting this done at least once a year or whenever strange noises start coming from under the hood. Taking care of these balance issues makes a real difference in day to day driving. Cars run smoother, last longer between repairs, and generally feel safer when navigating roads, especially during those long highway trips where every mile counts.

Safety Impacts of Severe Propshaft Imbalance

Drivetrain Disengagement Risks

When a propshaft becomes seriously out of balance, it can actually cause the drivetrain to disconnect completely from the engine. This means drivers might suddenly lose all control over their vehicles in worst case scenarios. According to industry data, problems with drivetrains account for quite a few road accidents caused by mechanical breakdowns each year. Understanding this danger makes regular maintenance absolutely necessary for keeping drivelines intact and avoiding dangerous situations while driving. Mechanics recommend checking propshafts during routine service appointments and making small adjustments as needed. These simple steps go a long way toward creating safer driving experiences and ensuring cars run reliably mile after mile down the highway.

High-Speed Stability Compromise

When going fast, small problems with the propshaft balance can really mess with how stable a car feels, which makes driving hazardous. A good working drivetrain matters a lot when it comes to keeping control, especially in bad weather or tricky road situations. Figuring out what level of imbalance is okay helps mechanics put in place fixes that keep vehicles steady at speed. Regular maintenance like this does more than just make driving safer it actually saves money in the long run by making parts last longer. Most drivers don't think about it much, but proper balancing work means fewer breakdowns and a generally better ride quality over time.

Catastrophic Failure Scenarios

When propshafts get seriously out of balance, cars can suffer major breakdowns that result in expensive repairs and sometimes even injuries. Looking back at accident records shows pretty clearly that many crashes happen because of unbalanced propshafts. Car owners should really think about sticking to proper maintenance schedules to avoid these kinds of problems. Regular inspections and timely balancing work go a long way toward preventing dangerous situations on the road. Most mechanics will tell drivers that keeping an eye on propshaft condition isn't just good practice but essential for anyone who wants their vehicle to last longer without unexpected troubles.

Performance and Efficiency Consequences

Fuel Economy Penalties from Parasitic Vibration

When a propshaft becomes unbalanced, it starts creating vibrations that actually waste more energy than necessary, making vehicles burn through fuel faster because of those extra losses. What happens here is pretty straightforward physics really. These vibrations create resistance inside the engine components, forcing the engine to work harder just to maintain normal operation, which naturally means more fuel gets burned than should be needed. Studies looking at actual driving conditions show that even small amounts of vibration can cut down on how far a car goes per tankful, which explains why fixing propshaft issues shouldn't wait until they become major problems. Keeping things balanced through regular checkups helps bring back that lost efficiency over time, something every driver wants when filling up at the pump.

NVH (Noise, Vibration, Harshness) Amplification

A propshaft that's out of balance isn't simply a mechanical problem. It actually makes noise, vibration, and harshness (those three N-V-H letters) way worse, which really cuts down on how enjoyable driving feels for anyone behind the wheel. The auto industry knows this all too well because studies show these NVH factors matter a lot when people decide if they like their cars or not. They directly impact how smooth or rough the ride feels day to day. If imbalances create these annoying vibrations, fixing them by properly balancing the shaft does wonders for customer satisfaction and often boosts those important product reviews online. Getting rid of these pesky NVH issues through good balancing techniques creates a much smoother driving atmosphere that car buyers appreciate and engineers take seriously when designing new models.

Power Transmission Inefficiencies

When a propshaft becomes unbalanced, it creates problems with how power moves through the drivetrain, which ultimately affects how well the car performs as a whole. The imbalance stops engine power from getting properly to the wheels, resulting in slower response times and reduced fuel economy. Research indicates that keeping propshafts in good balance makes cars respond better and run more efficiently. There's definitely a link between proper balance and overall performance, so regular checks should be part of any serious maintenance routine. A properly balanced propshaft ensures smoother operation across all driving conditions while maximizing what the vehicle can deliver.

The Balancing Machine Solution and Maintenance Protocols

Precision Balancing Techniques

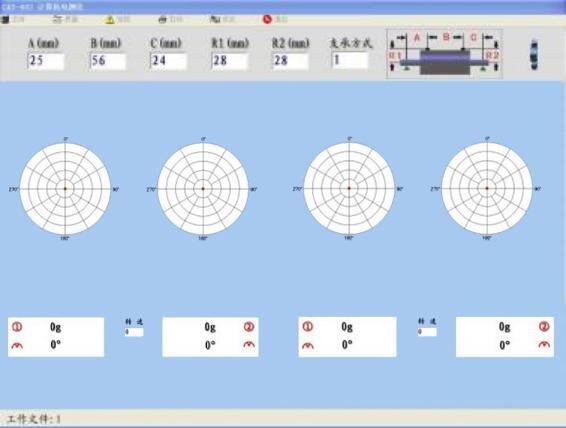

Getting propshaft imbalances right requires good precision balancing techniques. Today's balancing equipment from manufacturers including Shanghai Guangchun makes this possible through their advanced tech that spots and fixes even small imbalances accurately. When workshops make precision balancing part of their regular maintenance routine, vehicles run better for longer periods. The process itself uses special dynamic balancing machines capable of finding tiny problems in the shaft balance. This means smoother rides for drivers and less strain on other parts of the car over time. Mechanics who understand proper balancing methods see fewer comeback complaints about vibrations and premature component failure.

Diagnostic Equipment and Tolerance Standards

When shops use diagnostic gear that meets accepted tolerance levels, they get much better results when checking propshafts. The regular checks and tests can spot small balance issues before they turn into big problems that break down whole systems. Most auto repair businesses stick closely to these diagnostic guidelines because they know it keeps vehicles running properly for years instead of just months. Getting all this right means investing in modern tools capable of picking up tiny changes outside normal parameters. These tools aren't just fancy gadgets though they actually make a real difference in keeping cars and trucks operating safely on roads everywhere.

Preventative Maintenance Intervals

Getting regular maintenance done on schedule matters a lot for keeping propshafts balanced and running smoothly. When shops stick to proper maintenance intervals, they cut down on those annoying vibrations and other problems that come from imbalance. Writing everything down about when maintenance happens makes it easier to track what's been done, who did it, and when next service should happen. This simple record keeping actually saves money long term because mechanics catch small issues before they turn into big repairs. Most boat owners find that sticking with scheduled inspections means fewer breakdowns at sea and longer lifespan for their vessels overall.

FAQ

What is a propshaft, and why is its balance important?

A propshaft is a component that transfers torque from the engine to the wheels in a vehicle, crucial for driving performance. Its balance is important because imbalances can cause vibrations, discomfort, and potential mechanical failures, affecting the vehicle's safety and efficiency.

How can propshaft imbalance be detected early?

Propshaft imbalance can be detected early by monitoring speed-dependent vibration characteristics, recognizing auditory cues like knocking and clunking noises, and observing steering wheel feedback during driving.

What are the consequences of driving with an unbalanced propshaft?

Driving with an unbalanced propshaft can lead to accelerated component wear, reduce fuel economy, amplify NVH levels, compromise high-speed stability, and, in severe cases, cause catastrophic failures posing safety risks.

How does one achieve and maintain propshaft balance?

Propshaft balance can be achieved through precision balancing techniques, utilizing diagnostic equipment adhering to tolerance standards, and adhering to preventative maintenance intervals for regular assessment and correction.

Table of Contents

- Understanding Propshaft Function and Balance Requirements

- Vibration Patterns: Early Detection of Unbalanced Propshafts

- Component Degradation from Imbalance Forces

- Safety Impacts of Severe Propshaft Imbalance

- Performance and Efficiency Consequences

- The Balancing Machine Solution and Maintenance Protocols

- FAQ