Izbira najboljših balansnih strojev za maznike: strokovni nasveti

V sodobni proizvodnji in avtomobilski vzdrževanju je natančno uravnoteženje vrtečih se komponent ključno za optimalno zmogljivost in dolgo življenjsko dobo. Uravnoteževalni stroji za maznike predstavljajo bistveno opremo za zagotavljanje gladkega delovanja motorjev in industrijskih strojev. Ti napredni napravi pomagata odpraviti vibracije, zmanjšati obrabo in ohraniti splošno učinkovitost mehanskih sistemov.

Razumevanje tehnologije uravnoteženja maznika

Osnovna delovna načela

Sovremeni stroji za uravnoteženje mахovnikov uporabljajo napredne senzorje in sisteme za natančno merjenje, da zaznajo neuravnoves v rotirajočih komponentah. Te naprave merijo amplitudo vibracij in fazni kot, da določijo točno lokacijo in velikost neuravnovesa, kar omogoča natančno popravljanje z odstranjevanjem materiala ali dodajanjem uteži.

Ključne komponente in funkcije

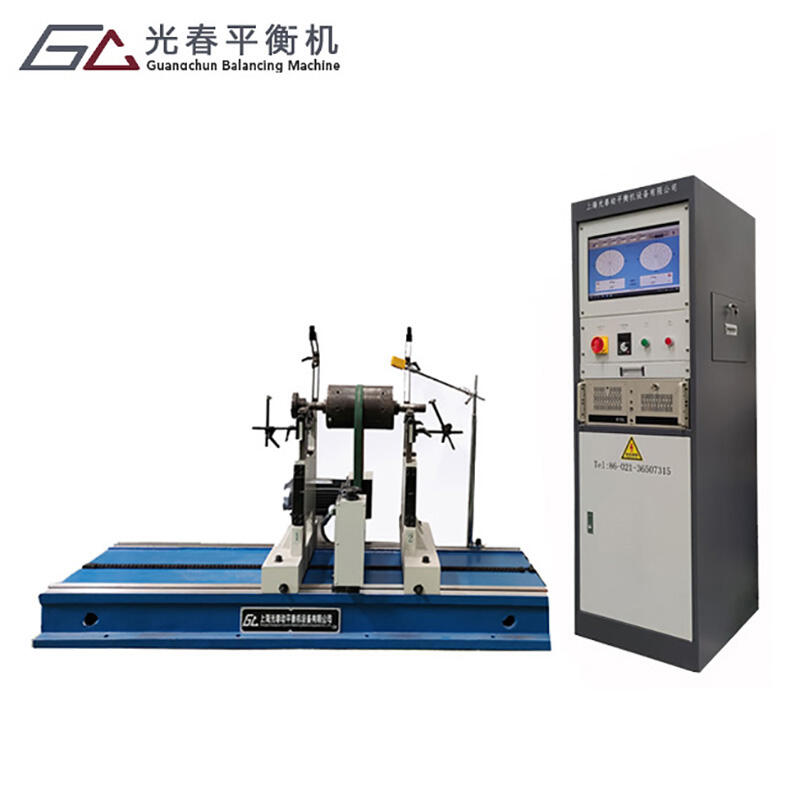

Glavne komponente uravnoteževalnih naprav za mazike vključujejo trdne nosilne podstavke, pogonske sisteme in sofisticirane merilne instrumente. Naprednejši modeli vključujejo digitalne zaslone, samodejne izračunske funkcije ter računalniško krmiljene operacije za izboljšano natančnost in učinkovitost postopka uravnoteženja.

Kriteriji izbire za industrijske aplikacije

Zahteve zmogljivosti

Pri izbiri uravnoteževalnih naprav za mazike je nosilna zmogljivost ključen dejavnik. Industrijski objekti morajo oceniti svoje običajne zahteve glede obremenitve in izbrati opremo, ki lahko sprejme največje komponente, hkrati pa ohranja natančnost pri celotnem razponu velikosti, s katerimi delajo.

Specifikacije natančnosti

Natančnost uravnoteževalnih strojev za maznik neposredno vpliva na kakovost končnega izdelka. Sodobni sistemi ponujajo ločljivost do delov grama, pri čemer nekateri specializirani stroji omogočajo še natančnejše meritve za visoko natančne aplikacije.

Napredne funkcije in tehnologije

Digitalna nadzorna sistema

Sodobni uravnoteževalni stroji za maznik vključujejo sofisticirane digitalne nadzorne sisteme, ki avtomatizirajo mnoge vidike postopka uravnoteženja. Ti sistemi zagotavljajo analizo podatkov v realnem času, avtomatske izračune popravkov in obsežne možnosti poročanja za namene kontrole kakovosti.

Kalibracija in održavanje

Redna kalibracija zagotavlja dosledno natančnost uravnoteževalnih strojev za maznik. Moderna oprema pogosto vključuje samodiagnostične zmogljivosti in avtomatizirane postopke kalibracije, da ohranja optimalno zmogljivost in zmanjša prostoj zaradi vzdrževanja.

Industrijske aplikacije in prednosti

Avtomobilska proizvodnja

Avtomobilska industrija se v veliki meri zanaša na uravnoteževalne stroje za maznik za kakovostno kontrolo pri proizvodnji motoričnih komponent. Ti stroji zagotavljajo, da mazniki izpolnjujejo stroge specifikacije glede uravnoteženosti, kar prispeva k gladkosti in dolgoživosti motorja.

Vzdrževanje industrijske opreme

V industrijskih okoljih imajo uravnoteževalni stroji za maznike pomembno vlogo pri vzdrževanju velikih strojev in opreme. Redno uravnoteževanje pomaga preprečiti predčasno obrabo, zmanjša porabo energije in podaljša delovno dobo rotirajočih komponent.

Pogosta vprašanja

Kakšna je tipična življenjska doba uravnoteževalnih strojev za maznike?

Pri ustrezni vzdrževanju in redni kalibraciji industrijski uravnoteževalni stroji za maznike običajno učinkovito delujejo 15–20 let. Tehnološki napredek pa lahko naredi nadgradnjo koristno že pred koncem tega obdobja.

Kako pogosto je treba uravnoteževalne stroje za maznike kalibrirati?

Priporočljivo je strokovno kalibriranje vsaj enkrat letno, pri napravah v intenzivni uporabi pa pogostejše prilagoditve ali tistih, ki obdelujejo natančne komponente. Dnevni preveritveni pregledi zagotavljajo dosledno zmogljivost.

Kateri dejavniki vplivajo na natančnost uravnoteženja?

Na točnost uravnoteženja vplivajo okoljski pogoji, vzdrževanje naprave, usposabljanje operaterja in nastavitev komponent. Še posebej pomembni so stabilnost temperature, izolacija proti vibracijam in pravilna namestitev temeljev.