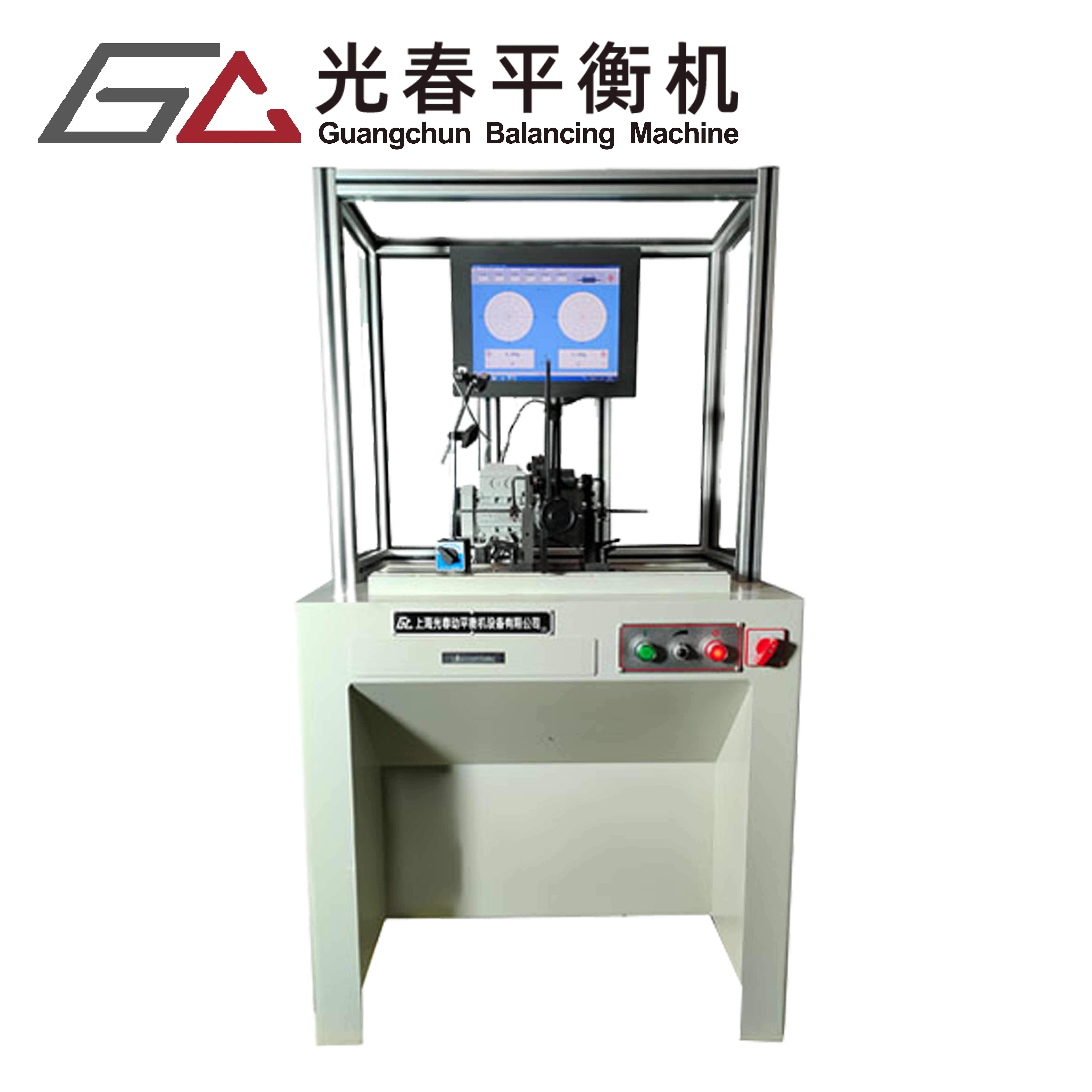

boat propeller balancing equipment

Boat propeller balancing equipment represents a crucial advancement in marine maintenance technology, offering precise measurements and adjustments to ensure optimal propeller performance. This sophisticated machinery utilizes state-of-the-art sensors and computerized analysis to detect even minimal imbalances in boat propellers, which can significantly impact vessel efficiency and longevity. The equipment typically consists of a robust mounting system, high-precision electronic sensors, and an advanced digital interface that provides real-time feedback during the balancing process. The system works by mounting the propeller on a specialized shaft that rotates at various speeds, allowing the sensors to detect vibrations and weight distribution inconsistencies. Modern boat propeller balancing equipment can identify imbalances as small as 0.1 gram, ensuring exceptional accuracy in the balancing process. This technology is essential for both recreational boats and commercial vessels, as it helps prevent damage caused by vibration, reduces fuel consumption, and extends the lifespan of the propulsion system. The equipment can handle propellers of various sizes and materials, making it versatile for different marine applications, from small pleasure craft to large commercial ships.