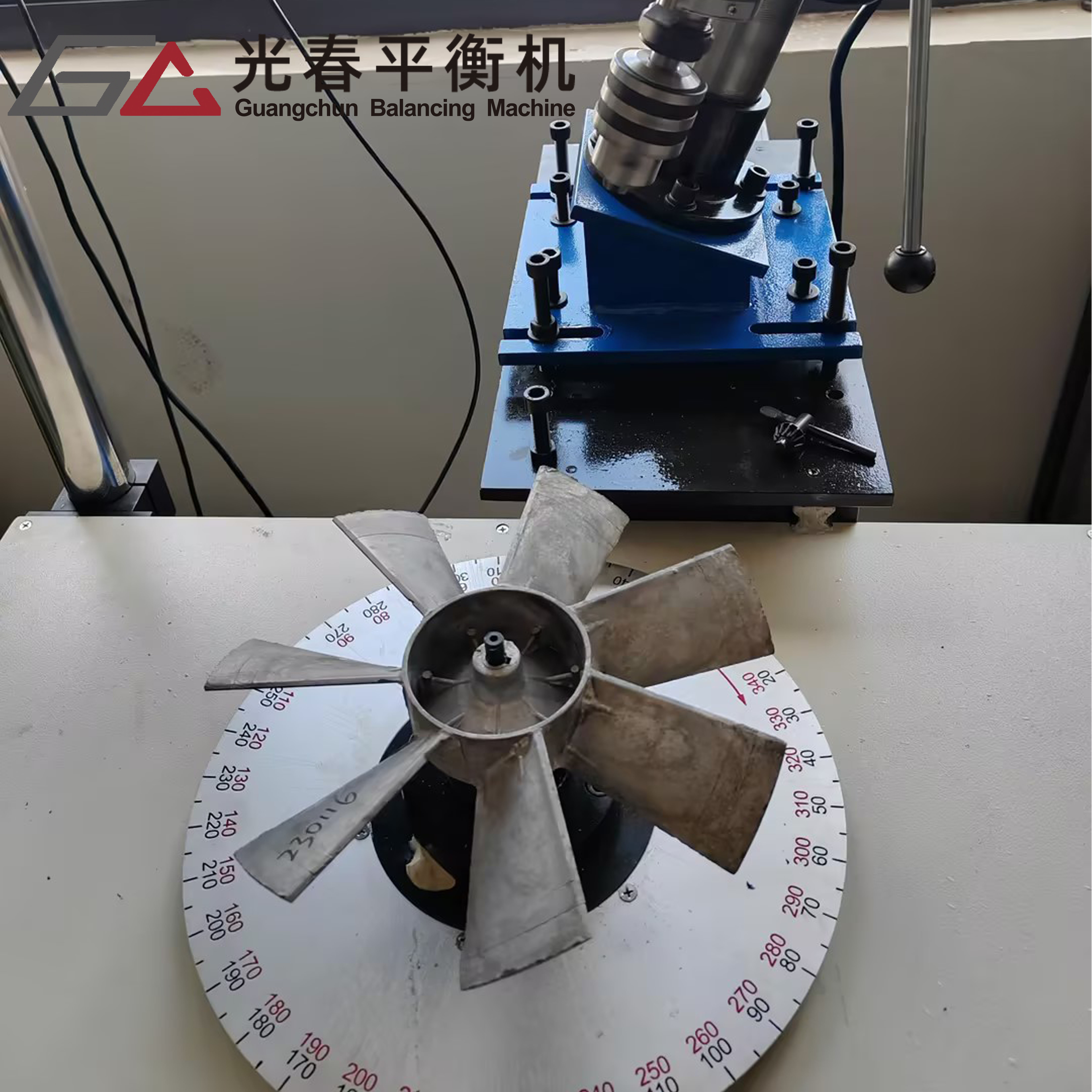

centrifuge impeller balancer

A centrifuge impeller balancer is a sophisticated piece of equipment designed to ensure optimal performance and longevity of centrifugal machinery. This precision instrument measures and corrects imbalances in rotating components, particularly impellers used in centrifuges, pumps, and other industrial equipment. The balancer employs advanced sensors and digital technology to detect even minute vibrations and weight distributions that could affect equipment performance. Operating through a combination of mechanical and electronic systems, it precisely identifies the location and magnitude of imbalances, allowing for accurate corrections through material removal or weight addition. The system typically includes a rigid mounting platform, high-sensitivity sensors, and sophisticated analysis software that processes real-time data to determine the exact adjustments needed. This technology is crucial in maintaining the integrity of industrial processes, as unbalanced impellers can lead to increased wear, reduced efficiency, and potential equipment failure. The balancer can handle various impeller sizes and designs, making it versatile across different industrial applications, from chemical processing to wastewater treatment. Modern centrifuge impeller balancers often feature automated calibration systems and user-friendly interfaces, enabling operators to achieve professional-grade balancing results with minimal training.