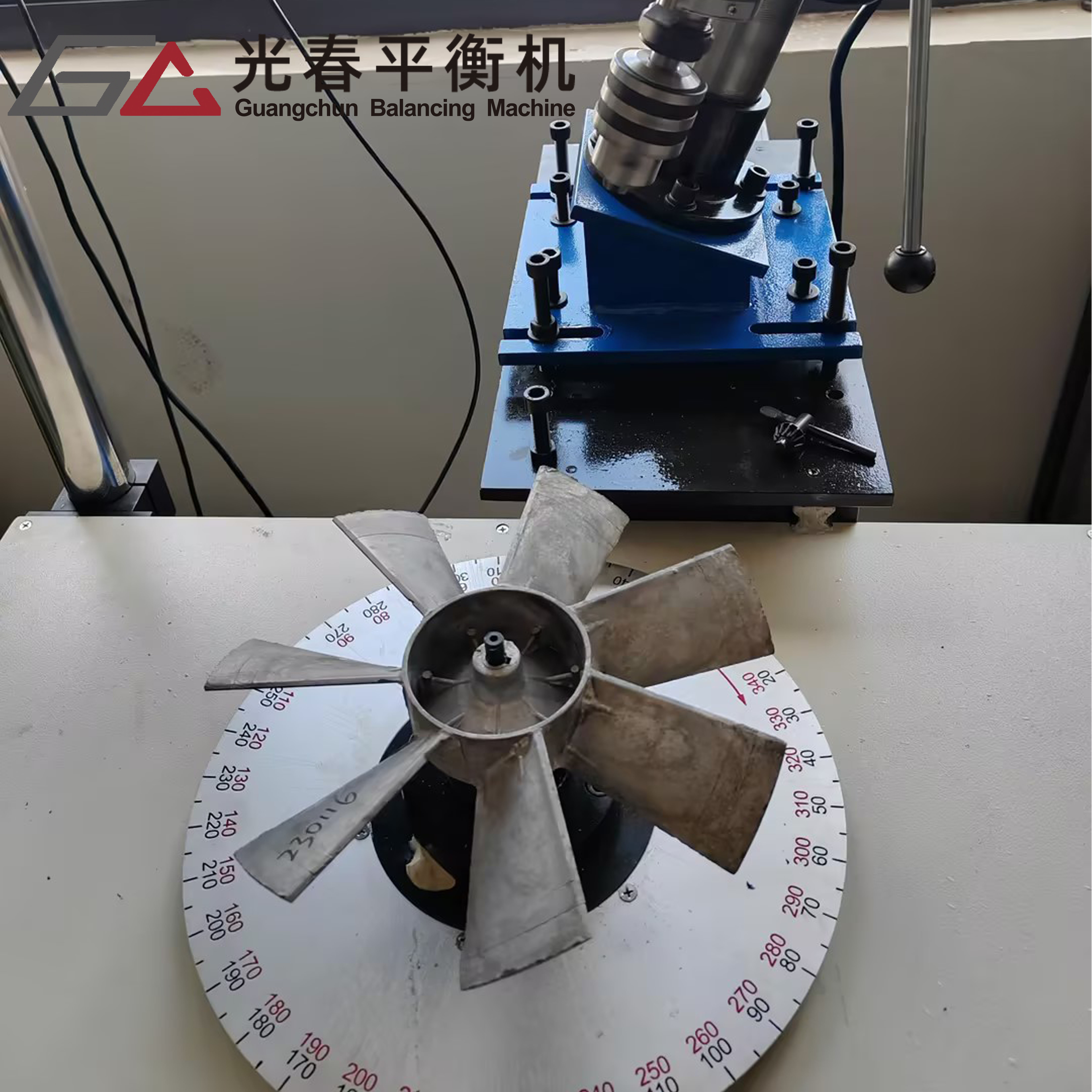

centrifuge impeller balancer for sale

The centrifuge impeller balancer is a sophisticated piece of equipment designed to ensure optimal performance and longevity of centrifugal machinery. This precision instrument employs advanced sensing technology to detect and correct imbalances in rotating components, particularly impellers used in centrifugal systems. The balancer utilizes state-of-the-art digital measurement systems to analyze vibration patterns and identify potential issues before they lead to equipment failure. Operating through a combination of mechanical and electronic components, the balancer can detect imbalances as small as 0.01 grams, ensuring unprecedented accuracy in measurement and correction. The system features an intuitive user interface that allows operators to monitor balancing operations in real-time and make necessary adjustments. Its versatile design accommodates various impeller sizes and configurations, making it suitable for applications across multiple industries, including chemical processing, wastewater treatment, and manufacturing. The balancer incorporates automated calibration procedures and self-diagnostic capabilities, significantly reducing the time required for maintenance operations while ensuring consistent accuracy in measurements.