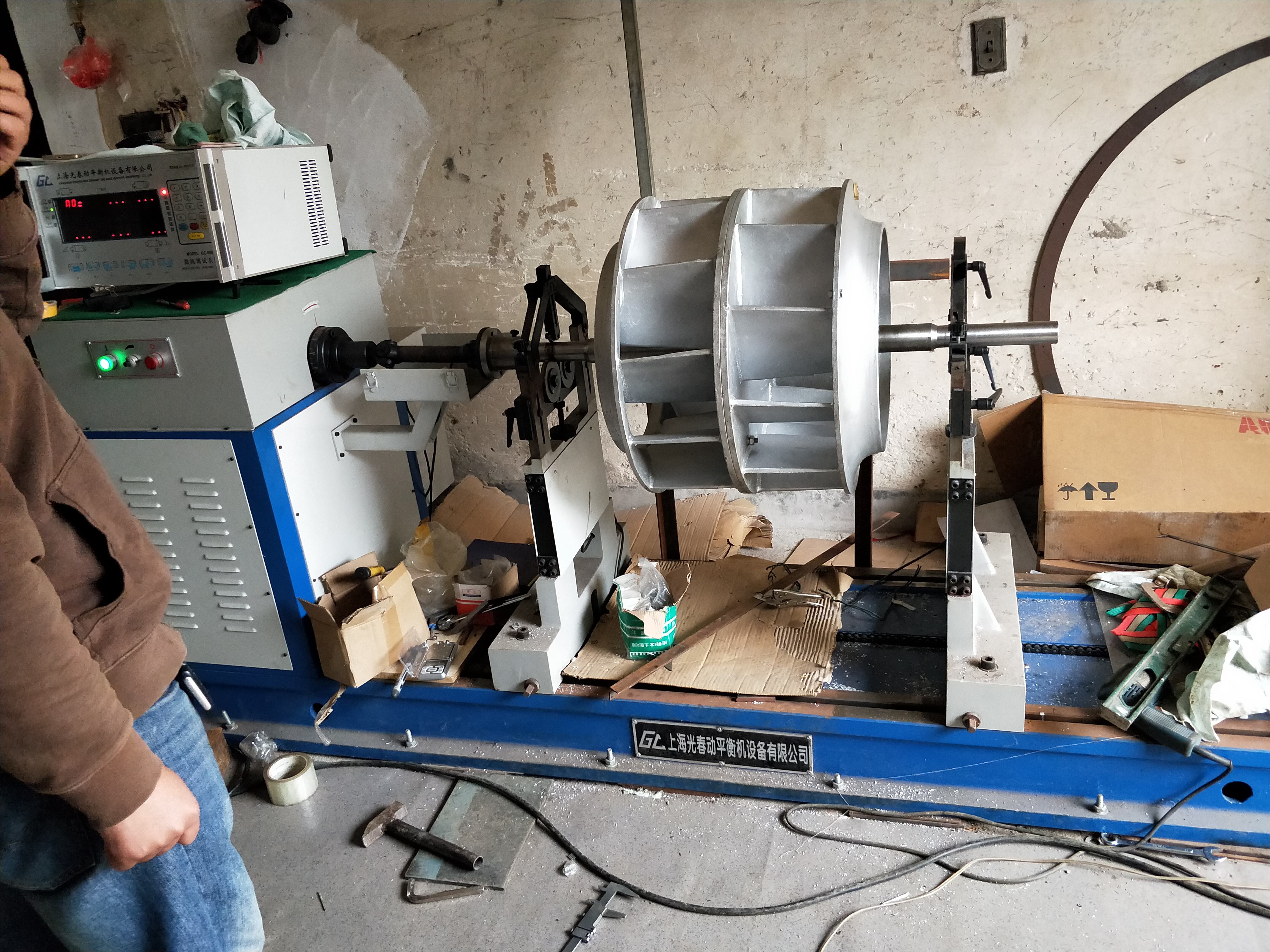

centrifuge impeller counterbalance

A centrifuge impeller counterbalance is a critical component in centrifugal systems designed to maintain operational stability and efficiency. This sophisticated mechanism works by offsetting the inherent imbalances that occur during high-speed rotation of the impeller assembly. The counterbalance system consists of precisely calculated weights strategically positioned to neutralize vibrations and ensure smooth operation at various speeds. In industrial applications, these counterbalances are engineered to withstand intense centrifugal forces while maintaining perfect equilibrium throughout the operational cycle. The technology incorporates advanced materials and precision engineering to achieve optimal balance correction, reducing wear on bearings and other vital components. Modern centrifuge impeller counterbalances often feature dynamic adjustment capabilities, allowing for real-time balance corrections as operating conditions change. This adaptability is particularly valuable in processes where load distribution may vary during operation. The system's design also includes sophisticated monitoring capabilities that help prevent equipment damage and maintain consistent performance levels. These counterbalances are essential in various industries, including chemical processing, wastewater treatment, and pharmaceutical manufacturing, where precise centrifugal separation is crucial for product quality and operational efficiency.