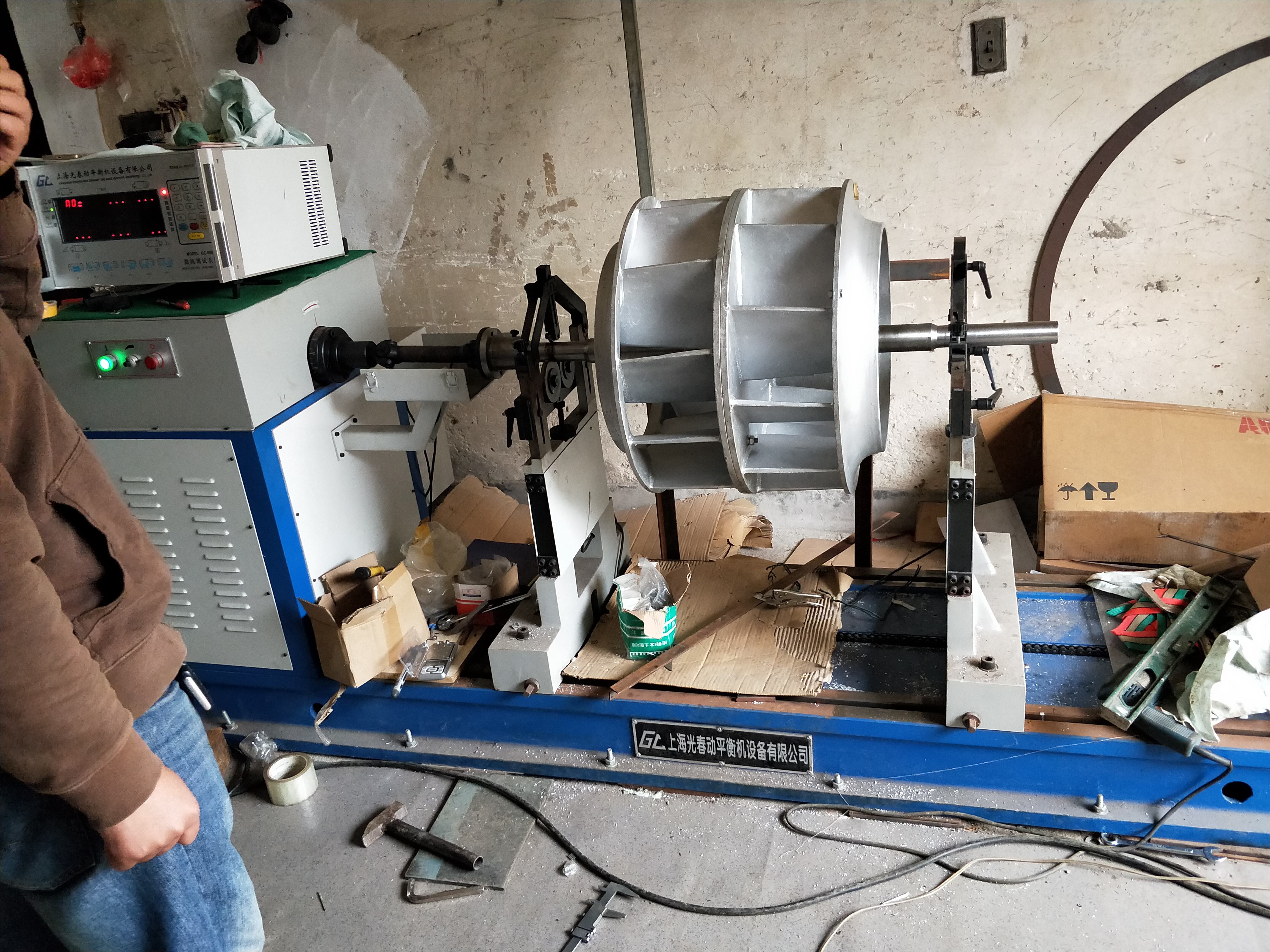

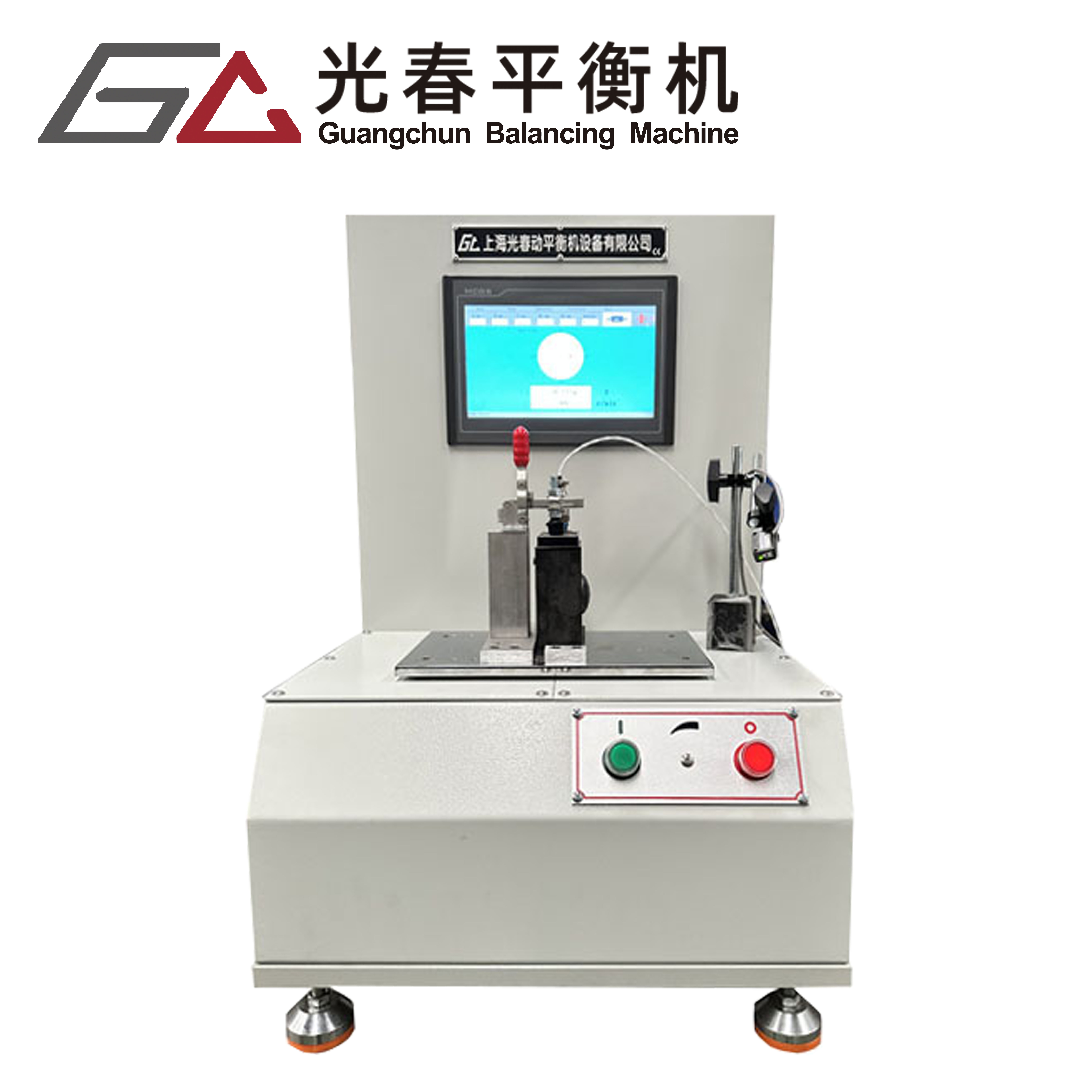

clutch balancing machine

A clutch balancing machine is a sophisticated piece of equipment designed to ensure optimal performance and longevity of automotive clutch assemblies. This precision instrument measures and corrects imbalances in clutch components through advanced sensing technology and automated adjustment mechanisms. The machine utilizes high-sensitivity sensors to detect even minimal vibrations and weight disparities in rotating clutch assemblies. During operation, the machine spins the clutch at various speeds to identify imbalances across different rotation frequencies. Its computerized system analyzes the data in real-time, providing accurate measurements of both static and dynamic imbalances. The machine's capability extends to handling various clutch sizes and types, from lightweight passenger vehicle clutches to heavy-duty industrial applications. It features advanced calibration systems that maintain accuracy over extended periods of use, ensuring consistent results. The integration of modern software allows for detailed reporting and data logging, enabling quality control tracking and maintenance scheduling. These machines are essential in automotive manufacturing, repair facilities, and quality control departments, where precise balancing is crucial for vehicle performance and safety.