driveshaft balancing

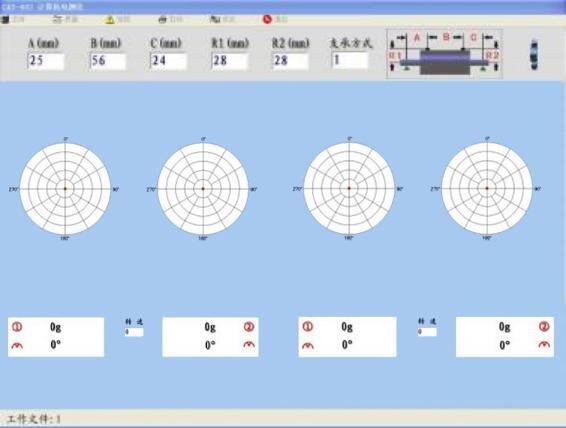

Driveshaft balancing is a critical maintenance procedure that ensures optimal performance and longevity of vehicle powertrains. This precise engineering process involves the careful measurement and correction of weight distribution along the driveshaft to eliminate vibrations and ensure smooth power transmission from the engine to the wheels. Using advanced electronic balancing equipment, technicians measure the dynamic and static balance of the driveshaft at various speeds, identifying any irregularities that could cause vibration, noise, or excessive wear. The process typically involves mounting the driveshaft on specialized balancing machines that can rotate it at operational speeds while sensitive sensors detect any imbalances. Corrections are made by strategically adding or removing weight from specific locations on the driveshaft. This technical procedure is essential for various vehicles, from passenger cars to heavy-duty trucks and industrial machinery. A properly balanced driveshaft ensures reduced wear on related components, including universal joints, bearings, and transmission systems. The technology has evolved significantly, now incorporating computer-aided precision measurements and real-time analysis to achieve optimal results. Regular driveshaft balancing is particularly important for high-performance vehicles and commercial fleet operations where reliability and efficiency are paramount.