high speed driveshaft balancing

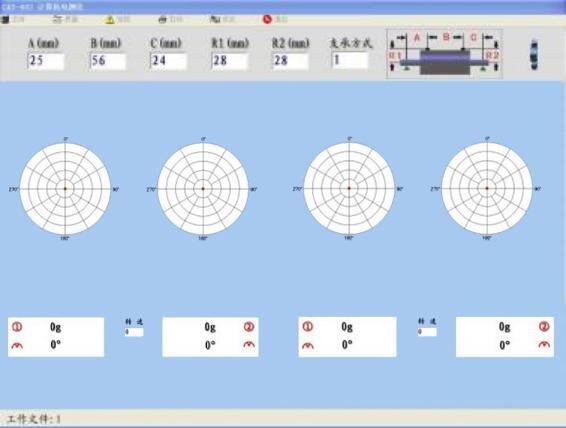

High speed driveshaft balancing is a critical process in maintaining the performance and longevity of rotating machinery components. This sophisticated procedure involves precise measurements and adjustments to ensure that the weight is evenly distributed around the shaft's rotational axis. The process utilizes advanced electronic balancing equipment that can detect even minute imbalances at high rotational speeds. During the balancing procedure, the driveshaft is mounted on specialized machinery that can simulate operational speeds while measuring vibration levels at multiple points. The technology employs sensitive sensors and computerized analysis to identify the exact locations where weight needs to be added or removed. This precise balancing is essential for various applications, including automotive powertrains, industrial machinery, and high-performance equipment. The process not only extends the life of mechanical components but also ensures smooth operation at high speeds, reducing wear and tear on bearings, universal joints, and supporting structures. Modern high speed driveshaft balancing equipment can handle shafts of various sizes and weights, making it versatile for different industrial applications. The procedure is particularly crucial for applications where driveshafts operate at speeds exceeding 3000 RPM, as even small imbalances can create significant vibration issues at these velocities.