propshaft balancing machine

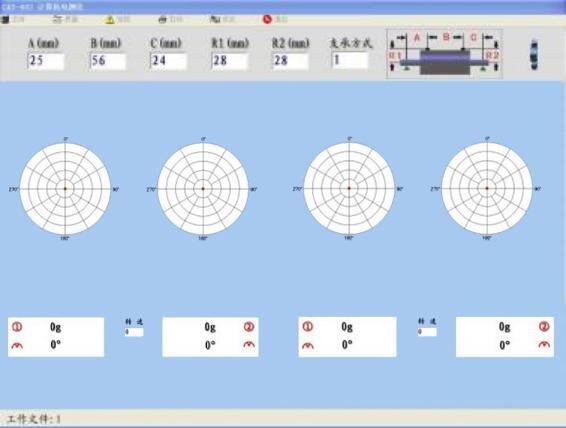

A propshaft balancing machine is a sophisticated piece of equipment designed to ensure the optimal performance and longevity of propeller shafts in various vehicles and industrial applications. This precision instrument measures and corrects imbalances in propshafts, which are crucial components in power transmission systems. The machine operates by mounting the propshaft between centers and rotating it at specific speeds to detect any weight disparities or geometric irregularities that could cause vibration. Using advanced sensors and computer-controlled measuring systems, it can identify the exact location and magnitude of imbalance with exceptional accuracy. The technology incorporates both horizontal and vertical plane measurements to achieve comprehensive balancing results. Modern propshaft balancing machines feature user-friendly interfaces that display real-time data and automated correction recommendations. They can accommodate various shaft sizes and weights, making them versatile for different industrial applications, from automotive manufacturing to heavy machinery maintenance. The balancing process typically involves multiple measurement runs at different speeds to ensure accuracy across the entire operating range. This precision equipment is essential for maintaining vehicle safety, reducing wear on components, and ensuring smooth power transmission in mechanical systems.