universal joint balancing machine

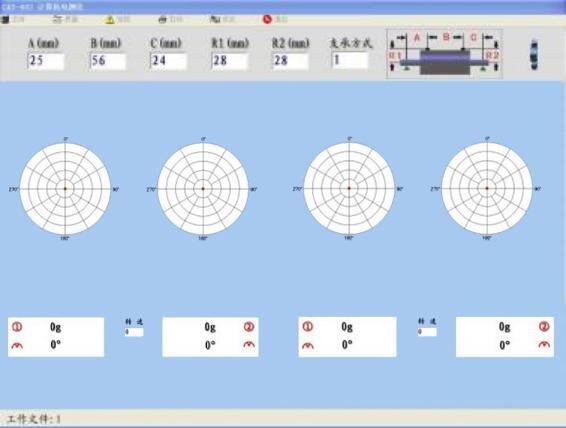

The universal joint balancing machine represents a crucial advancement in precision engineering, designed specifically for testing and correcting imbalances in universal joints, drive shafts, and related components. This sophisticated equipment operates by utilizing advanced sensors and computerized measuring systems to detect even minimal imbalances that could potentially lead to vibration, wear, and reduced performance in mechanical systems. The machine features a dual-plane balancing capability, allowing for simultaneous measurement and correction of both static and dynamic imbalances. Operating at variable speeds up to 3000 RPM, it can accommodate components of different sizes and weights, making it versatile for various industrial applications. The system employs high-precision piezoelectric sensors that measure vibration amplitude and phase angle, while its integrated software processes this data in real-time to determine the exact location and magnitude of imbalance. The correction process is guided by clear digital displays and automated calculations, ensuring precise material removal or weight addition for optimal balance. This machine finds extensive application in automotive manufacturing, heavy machinery production, and precision engineering industries, where component balance is critical for operational efficiency and equipment longevity.