semi truck drive shaft balancing

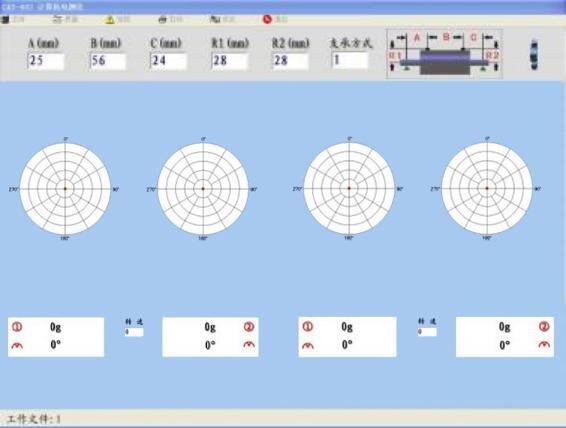

Semi truck drive shaft balancing is a critical maintenance procedure that ensures optimal performance and longevity of commercial vehicles. This precise engineering process involves analyzing and correcting weight distribution along the drive shaft, which is essential for transmitting power from the engine to the wheels. The procedure utilizes advanced computerized balancing equipment that can detect even minimal imbalances at various operating speeds. Technicians mount the drive shaft on specialized machinery that measures vibration levels and identifies exact locations where weight corrections are needed. The process involves both static and dynamic balancing techniques, ensuring the drive shaft rotates smoothly at all speeds. Modern balancing technology can achieve precision levels within 0.1 ounce-inches, resulting in significantly reduced vibration and wear. The procedure typically includes thorough inspection of components, measurement of runout, and strategic placement of balance weights. This maintenance service is particularly crucial for long-haul trucks that operate at sustained highway speeds, where even slight imbalances can lead to significant vibration issues and component wear.