fan balancing

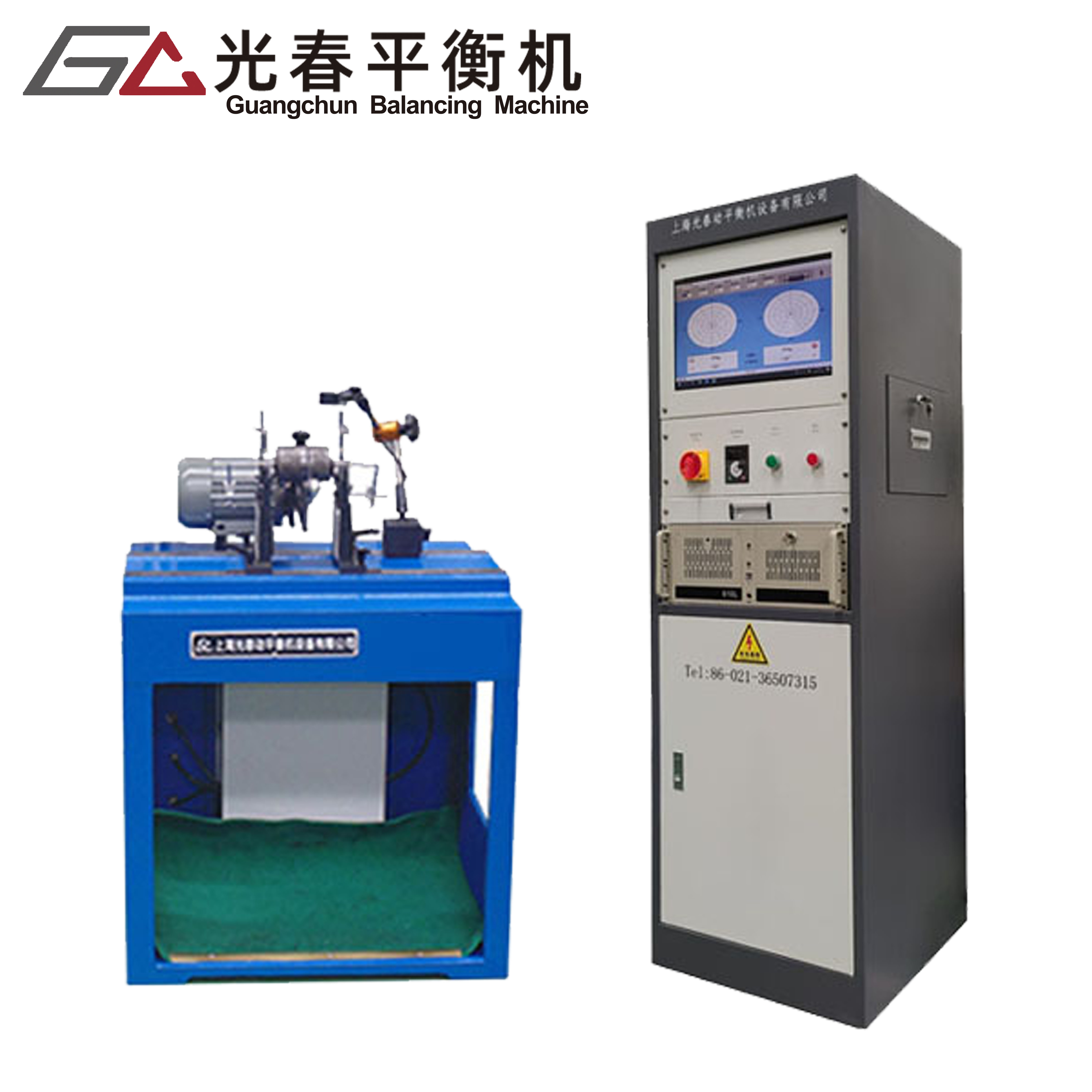

Fan balancing is a critical process in industrial and commercial applications that ensures optimal performance and longevity of rotating equipment. This precise mechanical procedure involves the systematic adjustment of weight distribution across fan blades and rotors to eliminate vibration and achieve smooth operation. The process utilizes advanced diagnostic equipment, including specialized balancing machines and vibration analyzers, to detect and correct imbalances that could lead to mechanical stress, energy inefficiency, and premature wear. Modern fan balancing techniques incorporate both static and dynamic balancing methods, with computerized systems providing real-time analysis and correction recommendations. The technology can handle various fan types, from small HVAC units to large industrial ventilation systems, ensuring each operates at peak efficiency. The process typically involves measuring vibration levels, identifying imbalance locations, calculating correction weights, and making precise adjustments until optimal balance is achieved. This comprehensive approach not only extends equipment life but also reduces energy consumption and maintains consistent airflow performance.