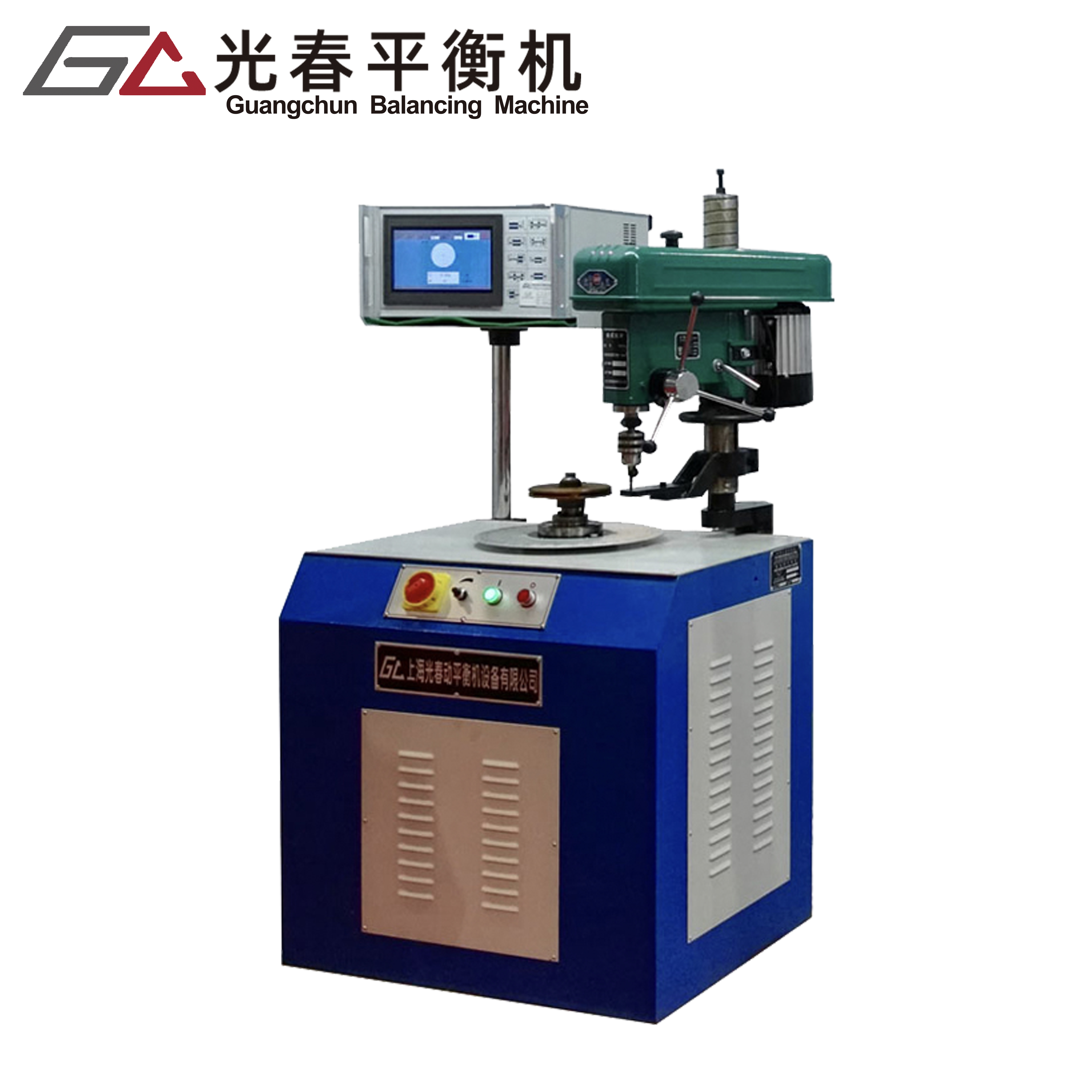

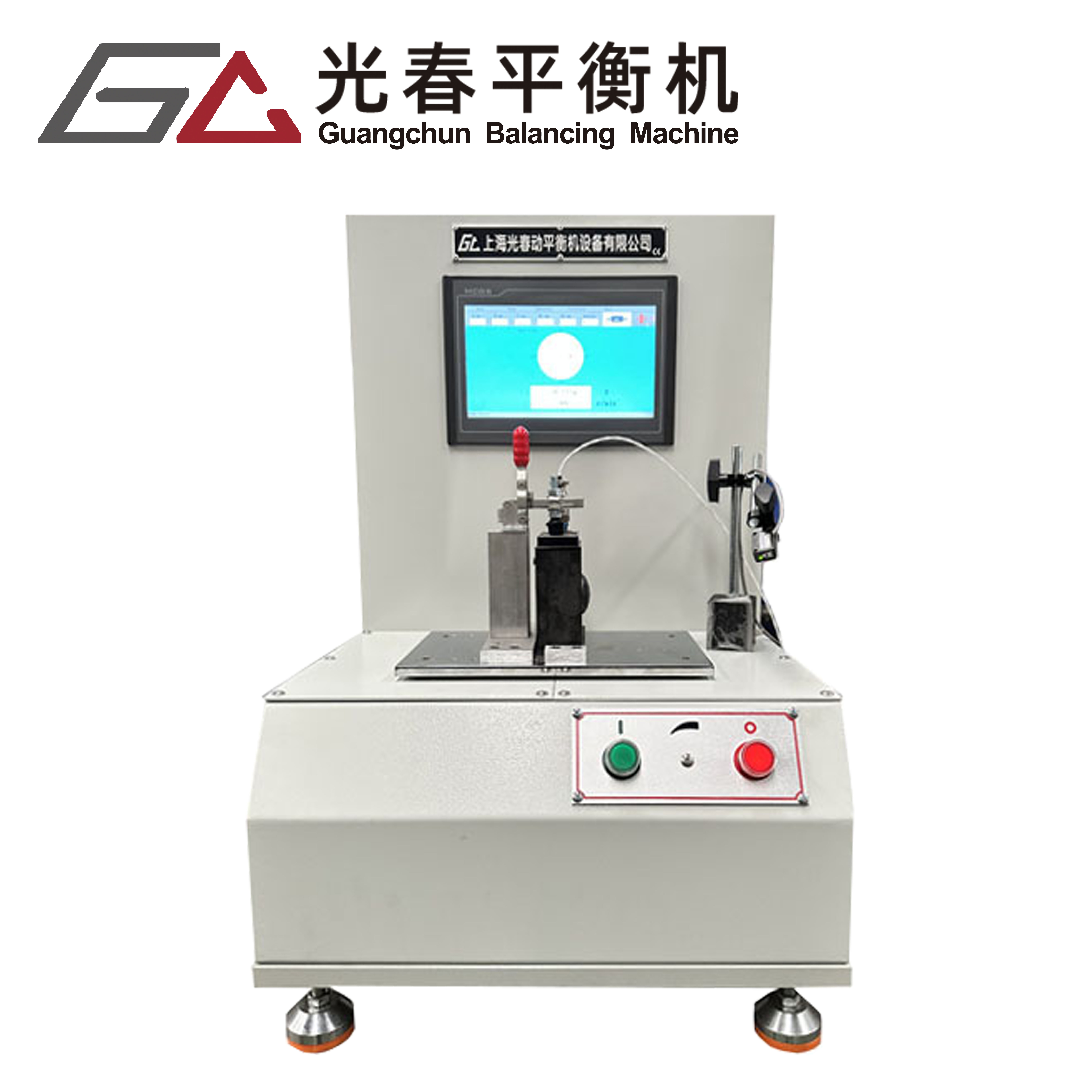

impeller balancing machine

An impeller balancing machine is a sophisticated piece of equipment designed to ensure optimal performance and longevity of rotating machinery components. This precision instrument measures and corrects imbalances in impellers, which are critical components in various industrial applications such as pumps, turbines, and compressors. The machine operates by mounting the impeller on a specialized spindle and rotating it at specific speeds to detect any uneven weight distribution. Using advanced sensor technology and computerized measurement systems, it identifies the location and magnitude of imbalance with exceptional accuracy. The machine's capabilities include both single-plane and dual-plane balancing, accommodating different impeller sizes and configurations. Modern impeller balancing machines feature digital displays and automated calculation systems that provide real-time data analysis and correction recommendations. They typically incorporate vibration sensors, angular position markers, and precision measurement tools to ensure accuracy down to micrometers. The technology enables operators to achieve balance qualities that meet or exceed ISO 1940 standards, ensuring optimal equipment performance and reliability. These machines are essential in manufacturing and maintenance operations, where they help prevent vibration-related issues, reduce wear and tear, and extend the operational life of rotating equipment.