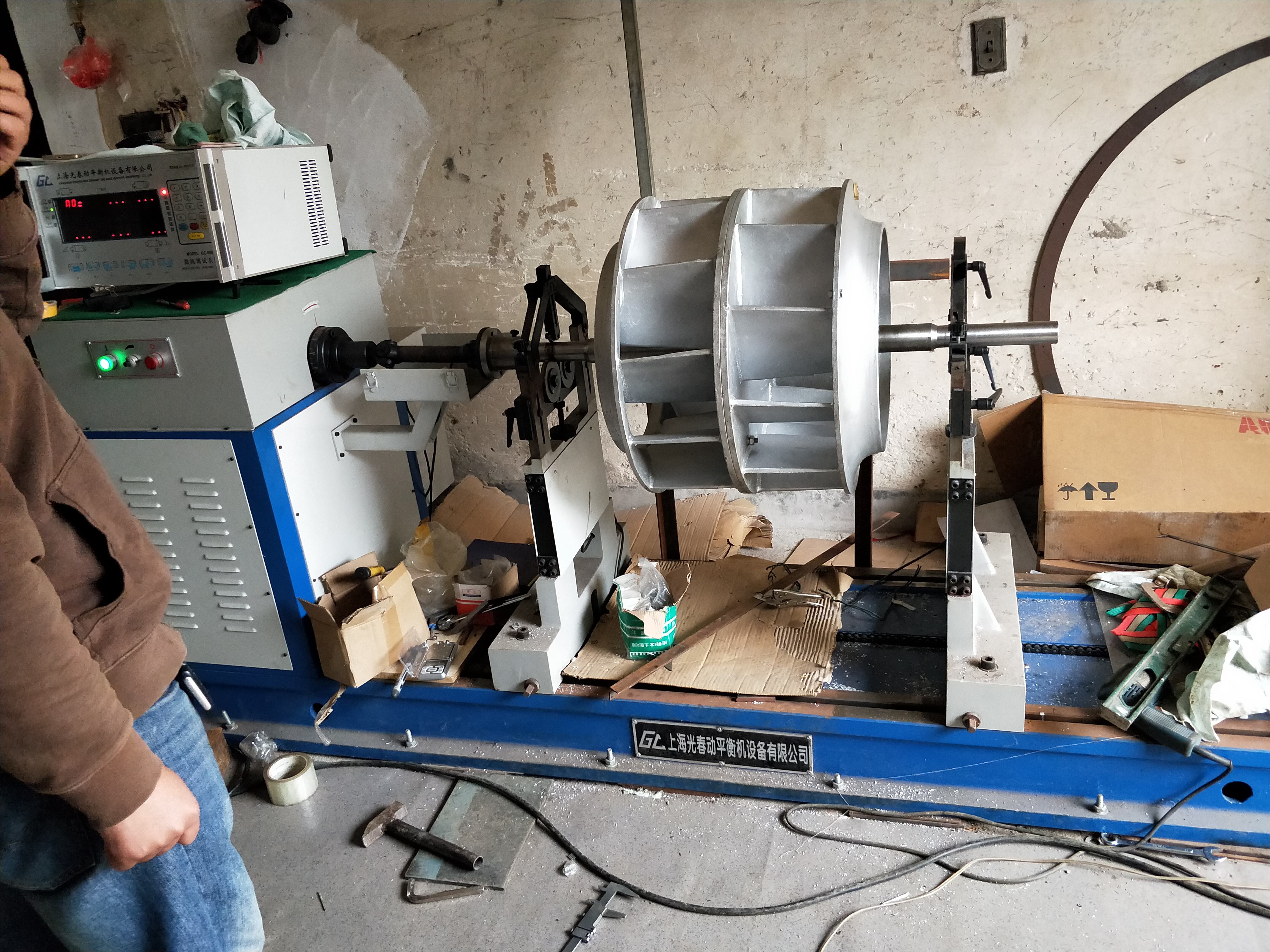

fan blades balancing machine

A fan blades balancing machine is a sophisticated piece of equipment designed to ensure optimal performance and longevity of industrial fans through precise balance measurement and correction. This specialized machinery employs advanced sensors and digital technology to detect imbalances in rotating fan assemblies, measuring both static and dynamic imbalance with exceptional accuracy. The machine operates by mounting the fan blade assembly onto a carefully calibrated spindle system, which then rotates at specific test speeds to gather comprehensive data about weight distribution and vibration patterns. Modern fan blade balancing machines incorporate computer-controlled systems that can automatically calculate correction weights and their optimal placement locations, significantly reducing the time and effort required for the balancing process. These machines are essential in various industries, including HVAC systems, industrial ventilation, power generation, and aerospace applications, where balanced fan operation is crucial for efficiency and safety. The technology allows for real-time monitoring and adjustment of balance conditions, ensuring that fan blades meet strict manufacturing specifications and operational requirements.