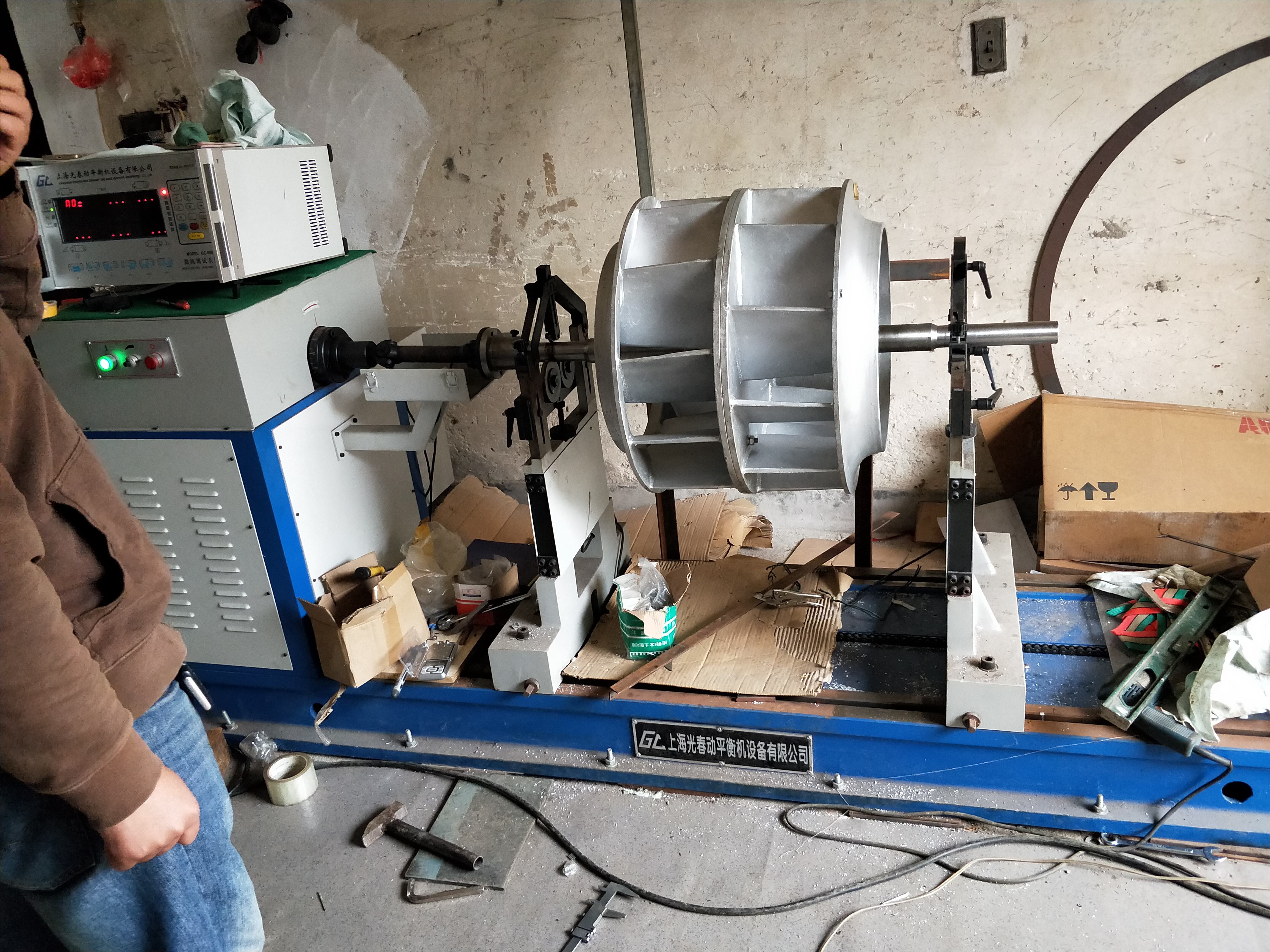

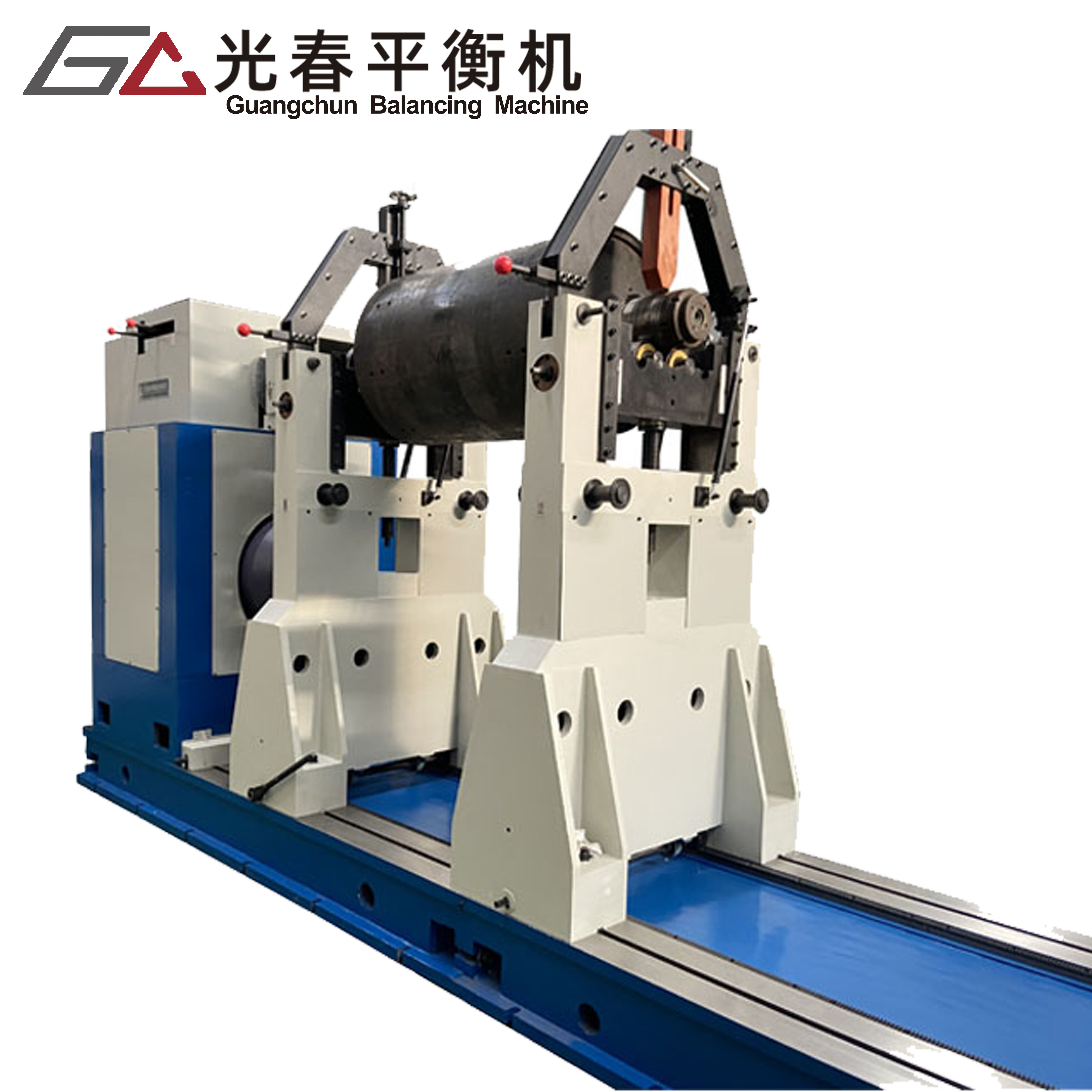

centrifugal fan balancer

A centrifugal fan balancer is a sophisticated piece of equipment designed to ensure optimal performance and longevity of centrifugal fans through precise balance measurement and correction. This essential tool combines advanced sensor technology with precise measurement capabilities to detect and correct imbalances in rotating components. The balancer works by analyzing the vibration patterns and rotational characteristics of the fan, identifying areas of uneven weight distribution that could lead to operational inefficiencies or mechanical wear. Using both static and dynamic balancing techniques, it can pinpoint exact locations where corrections are needed and determine the precise amount of weight that should be added or removed. The system typically includes high-sensitivity accelerometers, digital signal processing capabilities, and user-friendly interface software that provides real-time analysis and adjustment recommendations. Modern centrifugal fan balancers often feature automated calibration systems, multiple measurement planes for comprehensive analysis, and built-in quality control parameters. These devices are crucial in industrial settings, HVAC systems, power generation facilities, and manufacturing plants where maintaining optimal fan performance is essential for operational efficiency and equipment longevity.