blower balancing machine

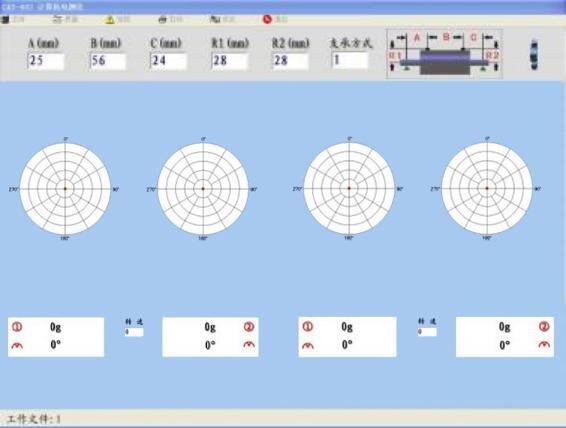

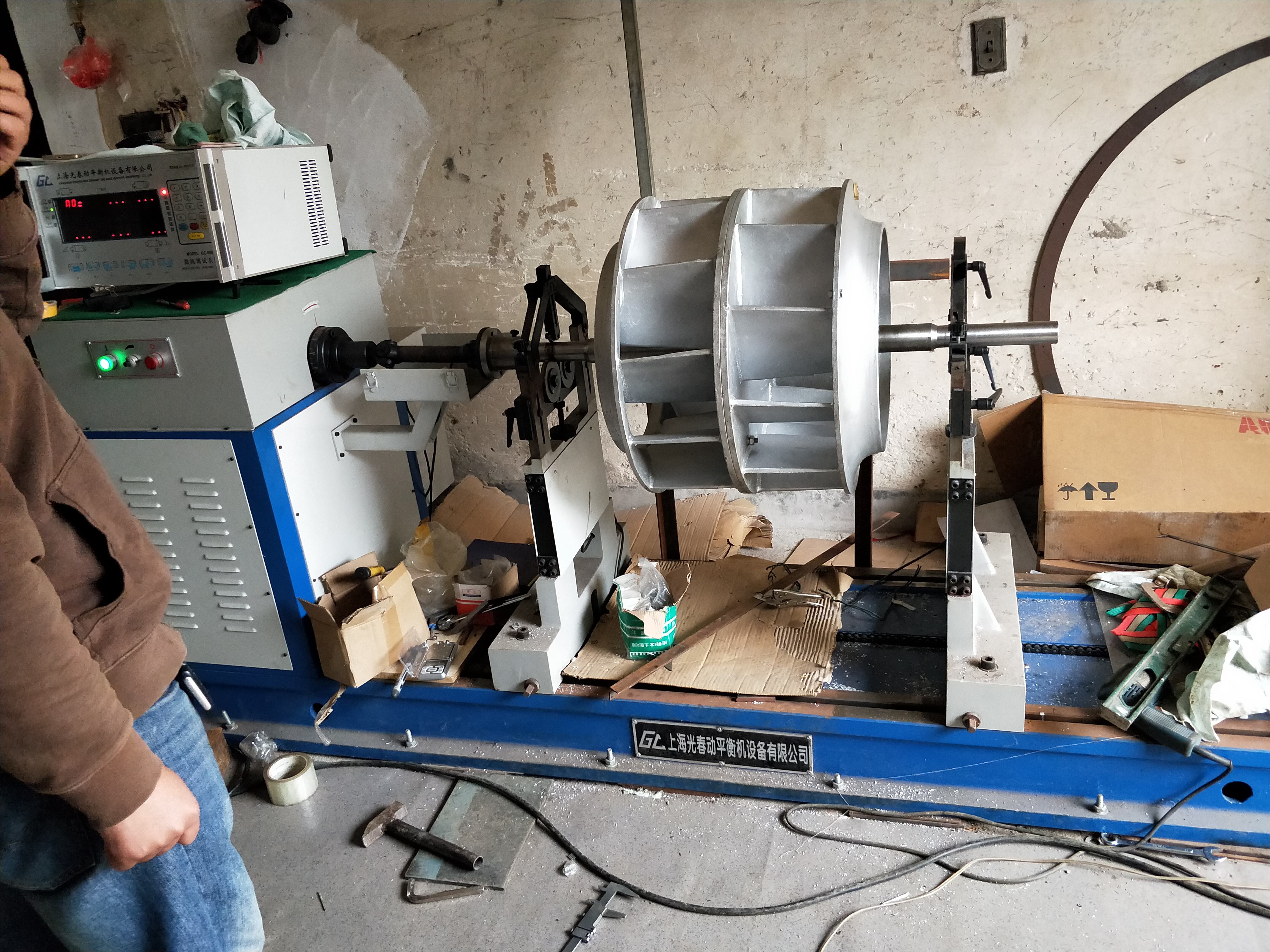

A blower balancing machine is a sophisticated piece of equipment designed to ensure optimal performance and longevity of industrial blowers through precise balance measurement and correction. This specialized machinery utilizes advanced sensors and computer-controlled systems to detect and analyze vibration patterns, identifying any imbalances in rotating components. The machine operates by mounting the blower on a specially designed test bed equipped with force-measuring sensors that can detect even minimal vibrations during operation. Through high-precision measurements, it determines the exact location and magnitude of imbalance, allowing for precise correction through weight addition or removal. The technology incorporates real-time monitoring systems and digital displays that provide immediate feedback on balance conditions. These machines are capable of handling various blower sizes and types, from small industrial fans to large centrifugal blowers, making them versatile tools for manufacturing and maintenance facilities. The balancing process typically involves multiple runs at different speeds to ensure comprehensive balance across the entire operating range, ensuring optimal performance under various conditions. Modern blower balancing machines often feature automated calibration systems and user-friendly interfaces that simplify the balancing process while maintaining high accuracy standards.