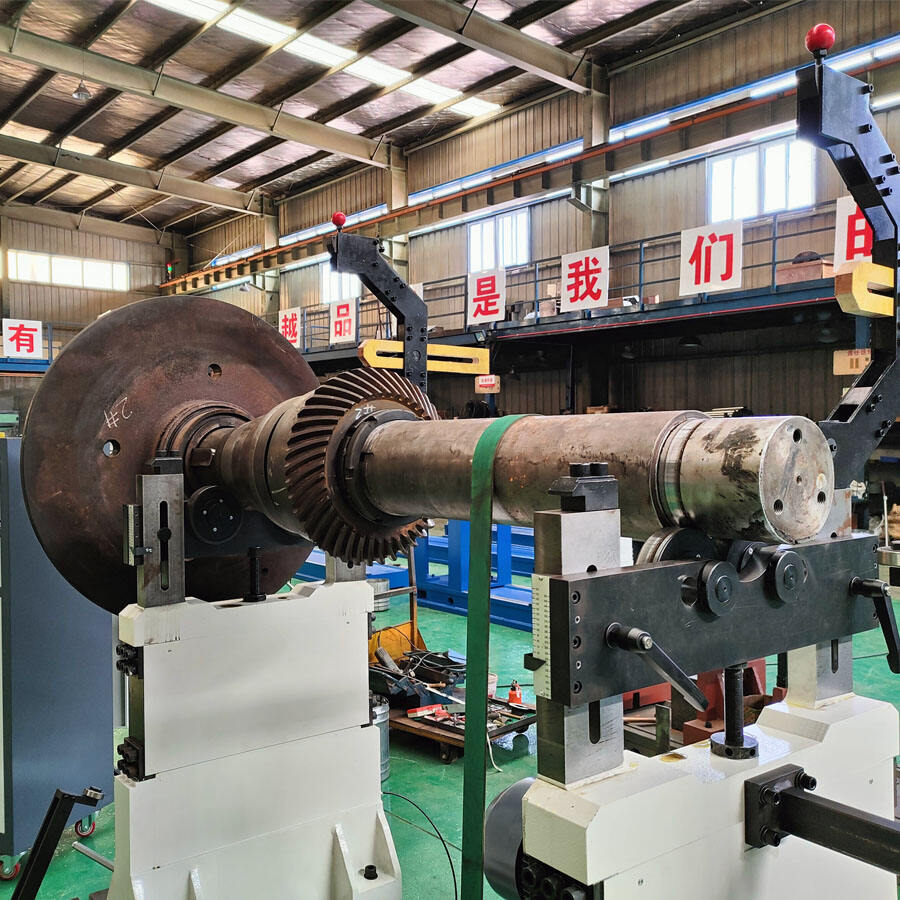

high precision products

High precision products represent the pinnacle of manufacturing excellence, incorporating advanced engineering principles and cutting-edge technology to deliver unparalleled accuracy and reliability. These sophisticated components are designed to meet the most demanding specifications across various industries, including aerospace, medical devices, and advanced electronics manufacturing. The products feature state-of-the-art measurement systems capable of maintaining tolerances down to micrometers, ensuring consistent performance in critical applications. They employ advanced materials and precision-engineered surfaces that minimize wear and maximize durability, while integrated quality control systems continuously monitor performance parameters to maintain optimal operation. The technology behind these products includes computer-aided design and manufacturing processes, automated inspection systems, and advanced calibration protocols that ensure each component meets rigorous quality standards. These products serve essential roles in applications requiring extreme precision, from surgical instruments to satellite components, where even minimal deviations could have significant consequences. The manufacturing process involves multiple stages of quality verification, environmental controls, and sophisticated testing procedures to guarantee reliability and accuracy.