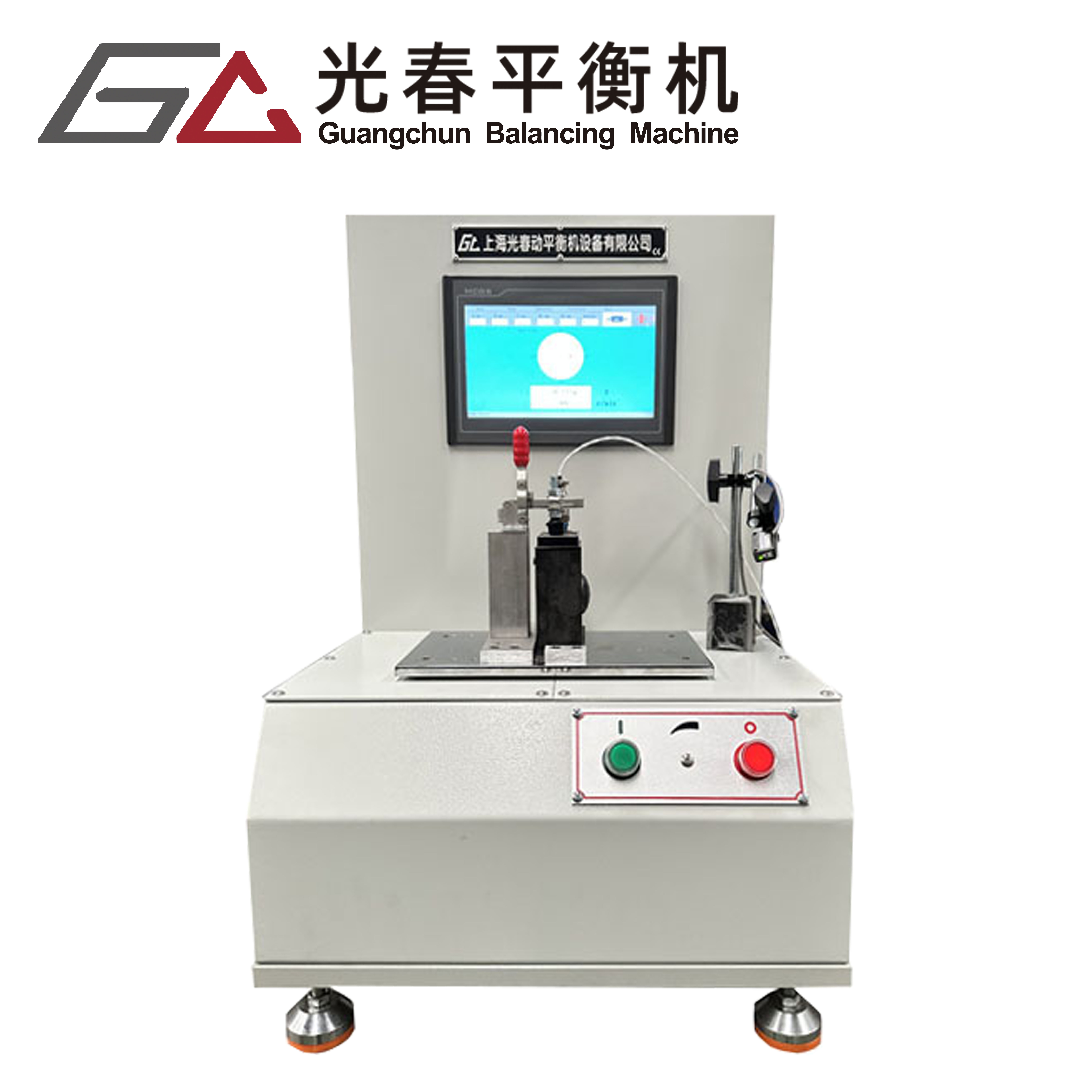

rotor balancing machine

A rotor balancing machine is a sophisticated piece of equipment designed to detect and correct imbalances in rotating components across various industrial applications. This precision instrument measures the distribution of mass around a rotation axis, ensuring optimal performance and longevity of rotating equipment. The machine operates by spinning the rotor at specific speeds while using sensitive sensors to detect vibration patterns and imbalances. Modern rotor balancing machines incorporate advanced digital technology, featuring high-precision measuring systems capable of detecting microscopic imbalances. These machines can handle rotors of various sizes and weights, from small electric motor armatures to large industrial turbines. The technology employs both hard-bearing and soft-bearing balancing methods, depending on the specific requirements of the component being balanced. Key features include automatic measurement cycles, real-time data analysis, and computer-controlled operation systems that provide detailed reports and correction recommendations. The machine's versatility allows it to serve multiple industries, including automotive manufacturing, aerospace, power generation, and general industrial applications. This essential equipment ensures that rotating components meet strict balance specifications, ultimately contributing to reduced vibration, improved efficiency, and extended equipment life.