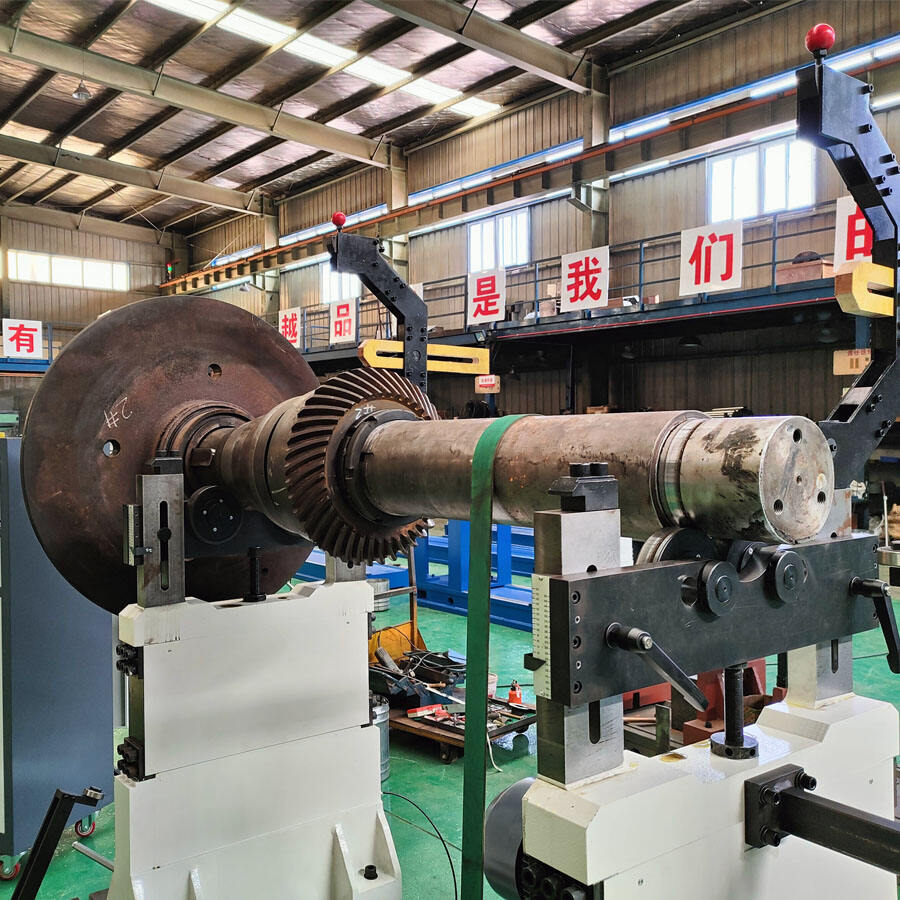

rotor balancing equipment

Rotor balancing equipment represents a critical advancement in industrial machinery maintenance and quality control. This sophisticated system is designed to detect and correct imbalances in rotating components, ensuring optimal performance and longevity of industrial equipment. The equipment utilizes state-of-the-art sensors and digital technology to measure vibration levels, automatically calculate correction weights, and determine precise locations for weight placement. Operating across multiple planes, these systems can handle rotors of various sizes and weights, from small electric motor armatures to large industrial turbines. The technology incorporates high-precision measuring capabilities, typically operating with accuracy levels down to micrometers, enabling the detection of even minimal imbalances that could potentially cause equipment failure. Modern rotor balancing equipment features user-friendly interfaces with touch-screen controls, real-time data analysis, and comprehensive reporting capabilities. These systems often include automated calibration processes, dynamic measurement capabilities, and built-in quality control parameters. The equipment's versatility allows for both horizontal and vertical balancing configurations, making it suitable for a wide range of applications across manufacturing, power generation, aerospace, and automotive industries. Advanced models include features such as automatic rotor recognition, specialized balancing programs for different rotor types, and network connectivity for data sharing and remote diagnostics.