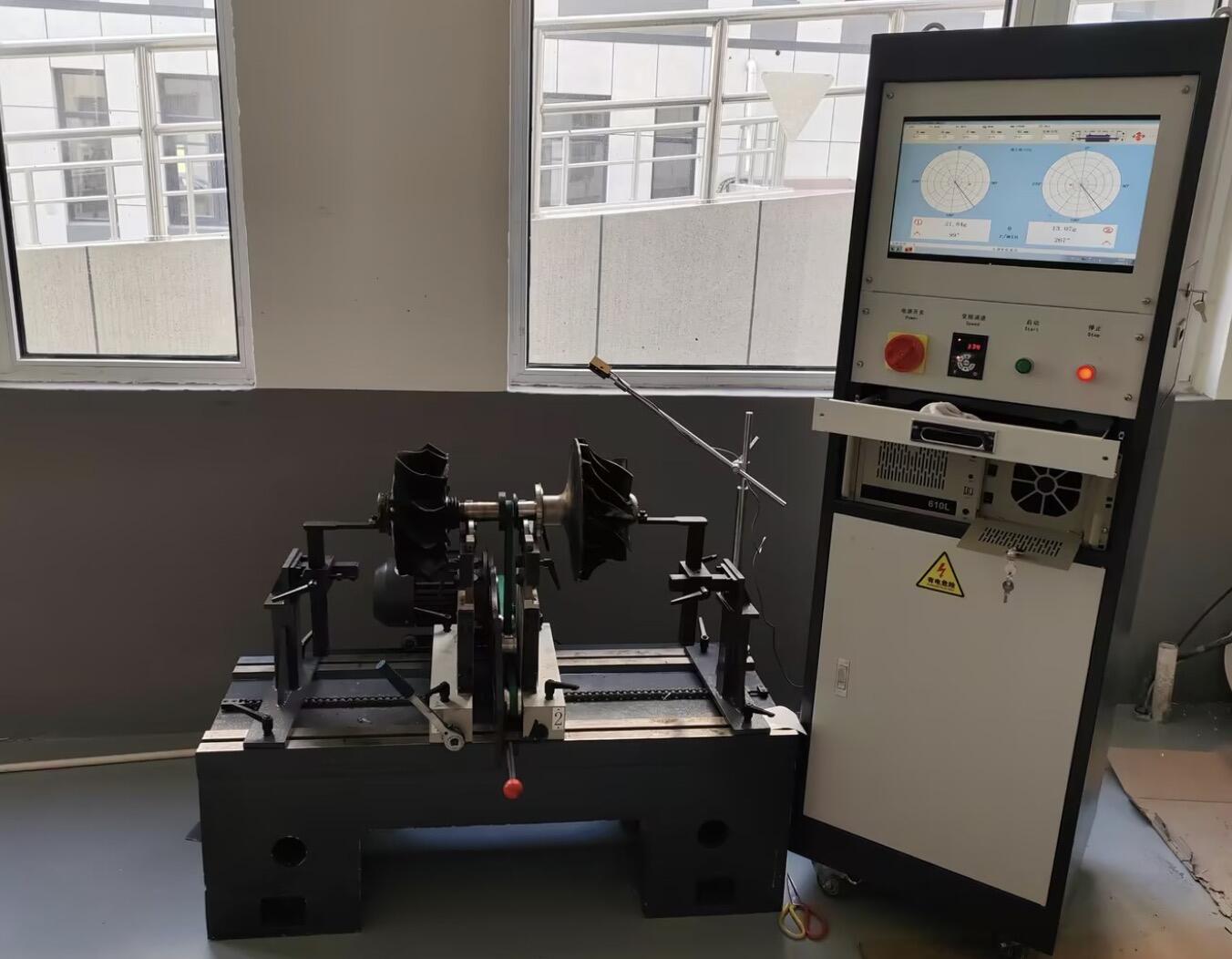

rotor balance

A rotor balance is a critical precision measurement and adjustment process essential for maintaining the optimal performance of rotating machinery. This sophisticated system analyzes and corrects uneven weight distribution in rotating components, ensuring smooth operation across various industrial applications. The technology employs advanced sensors and computerized analysis to detect imbalances as minimal as fractions of a gram, operating at both low and high speeds to provide comprehensive diagnostic data. Modern rotor balancing systems utilize digital technology to measure vibration amplitude and phase angles, creating detailed reports of imbalance conditions. The process involves both static and dynamic balancing techniques, with static balancing addressing single-plane issues and dynamic balancing handling complex multi-plane scenarios. These systems can operate in real-time, allowing for continuous monitoring and adjustment of rotating equipment during operation. Applications span across numerous industries, including automotive manufacturing, aerospace engineering, power generation, and industrial manufacturing. The technology has evolved to incorporate artificial intelligence and machine learning capabilities, enabling predictive maintenance and automated correction protocols. This advancement has significantly reduced equipment downtime and extended the operational lifespan of rotating machinery.