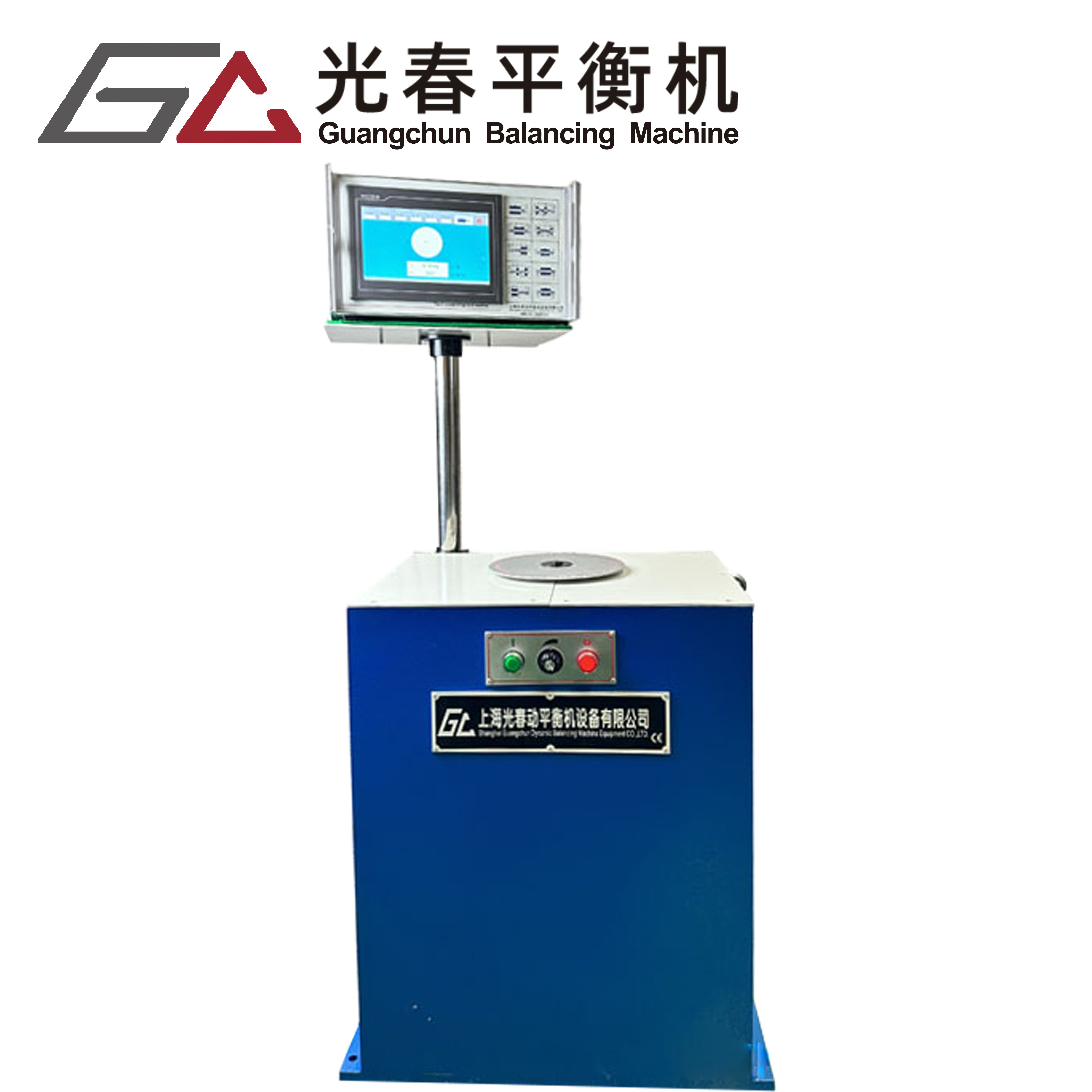

unbalance detection

Unbalance detection is a critical technological process that identifies and measures asymmetrical distribution of weight in rotating machinery and equipment. This sophisticated system employs advanced sensors and analytical algorithms to monitor vibration patterns, rotational speeds, and displacement measurements in real-time. The technology operates by detecting variations in the centrifugal forces generated during rotation, which can indicate potential imbalances in components such as rotors, shafts, or wheels. Modern unbalance detection systems incorporate digital signal processing capabilities that can differentiate between various types of mechanical irregularities, ensuring precise identification of balance-related issues. These systems are extensively utilized across multiple industries, including manufacturing, automotive, aerospace, and power generation. The technology proves particularly valuable in predictive maintenance programs, where early detection of imbalances can prevent catastrophic equipment failures and reduce maintenance costs. Contemporary unbalance detection systems often feature integrated data logging capabilities, allowing for trend analysis and historical performance tracking. This enables maintenance teams to make informed decisions about equipment maintenance schedules and replacement timing. The technology has evolved to include wireless monitoring capabilities and cloud-based data storage, making it more accessible and efficient for various applications.