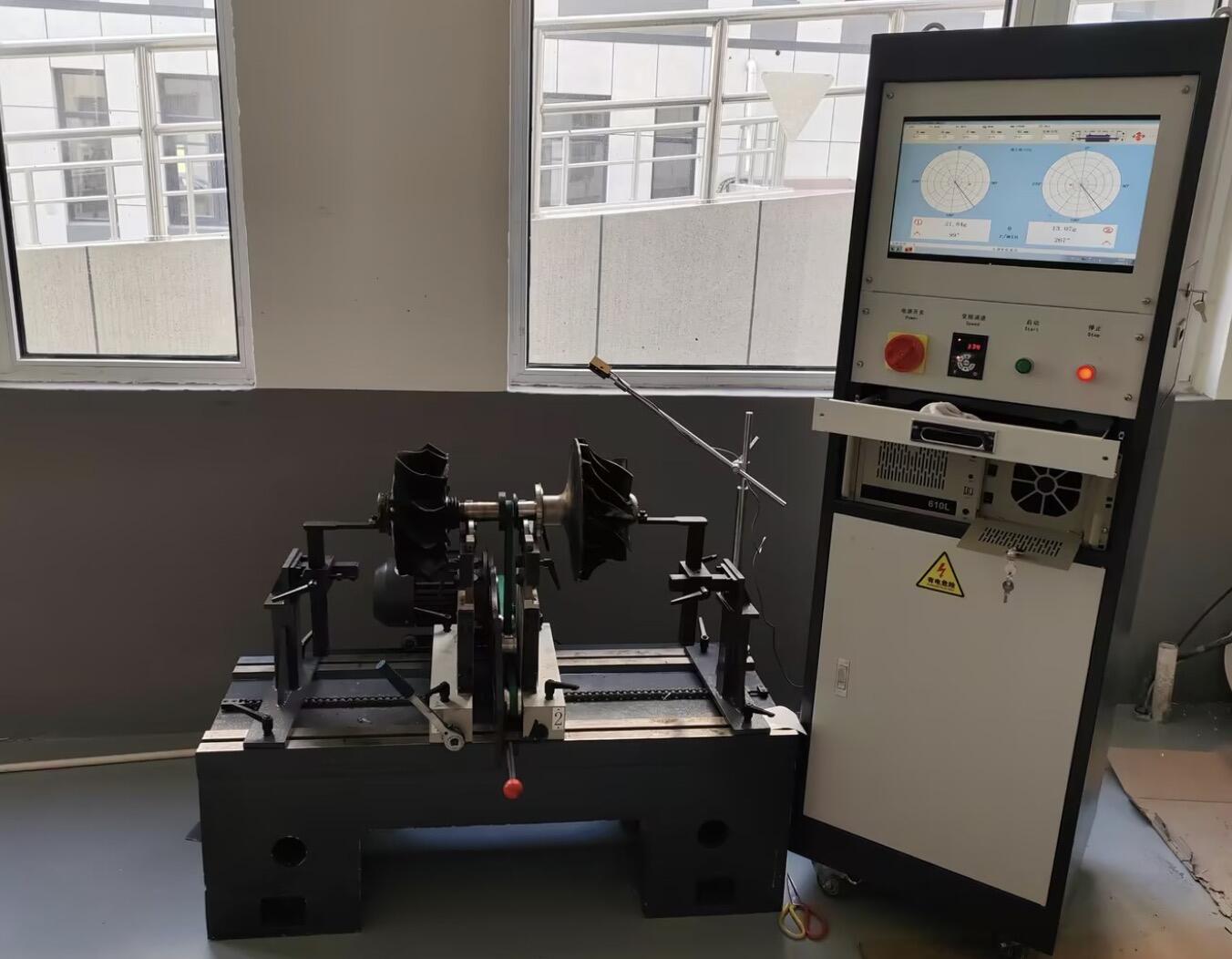

new dynamic balancing machine

The new dynamic balancing machine represents a significant advancement in precision engineering and quality control technology. This state-of-the-art system utilizes advanced sensors and real-time monitoring capabilities to detect and correct imbalances in rotating components with unprecedented accuracy. The machine incorporates dual-plane measurement technology, enabling simultaneous analysis of multiple axes while maintaining an impressive accuracy of up to 0.1 g.mm. Its versatile design accommodates a wide range of components, from small turbine rotors to large industrial fans, with a maximum workpiece weight capacity of 1000kg. The system features an intuitive touch-screen interface that guides operators through the balancing process, complete with automated measurement sequences and instant result visualization. Built-in quality control protocols ensure consistent performance across multiple operations, while the integrated data logging system maintains comprehensive records for quality assurance and traceability. The machine's robust construction and vibration-isolated foundation guarantee reliable measurements even in challenging industrial environments. Additionally, its energy-efficient design and quick setup capabilities contribute to reduced operational costs and improved productivity.