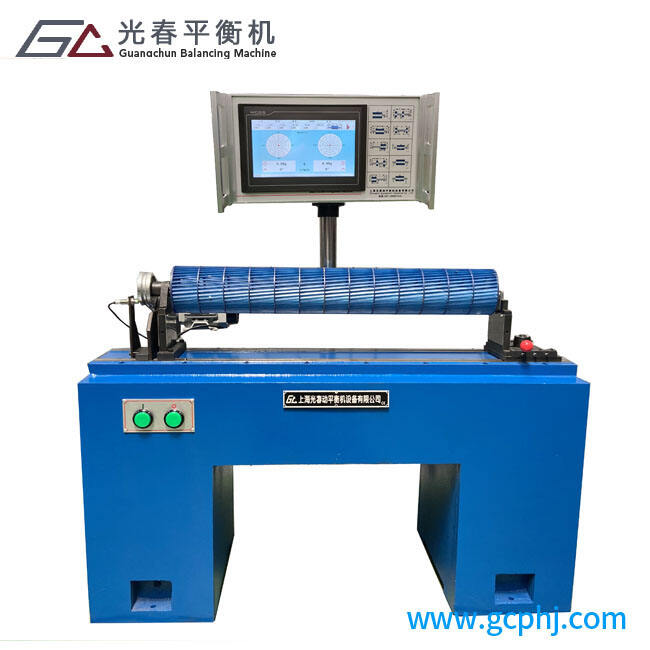

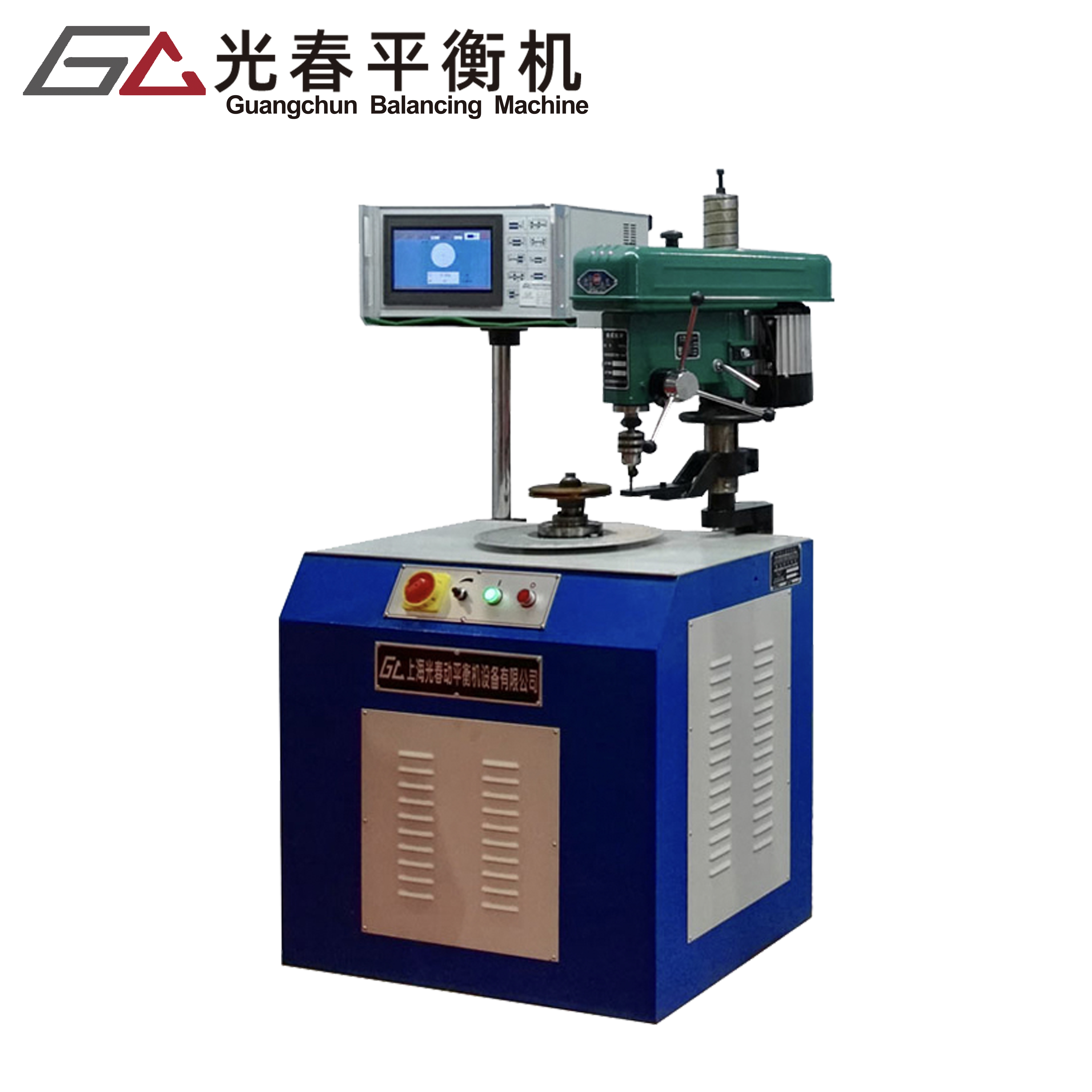

horizontal balancing machine

A horizontal balancing machine is a precision engineering instrument designed to detect and correct imbalances in rotating components. This sophisticated equipment operates by mounting the workpiece horizontally between bearing pedestals, allowing it to rotate at specific speeds for accurate measurement. The machine utilizes advanced sensors and digital technology to measure vibration amplitudes and phase angles, precisely identifying the location and magnitude of unbalance. Operating through a combination of mechanical and electronic systems, it can handle various components ranging from small rotors to large industrial machinery parts. The machine's measuring system typically consists of piezoelectric sensors, digital signal processors, and a computerized interface that provides real-time analysis and correction recommendations. Modern horizontal balancing machines feature automatic calibration capabilities, multiple plane balancing options, and user-friendly software interfaces that

Get A Quote