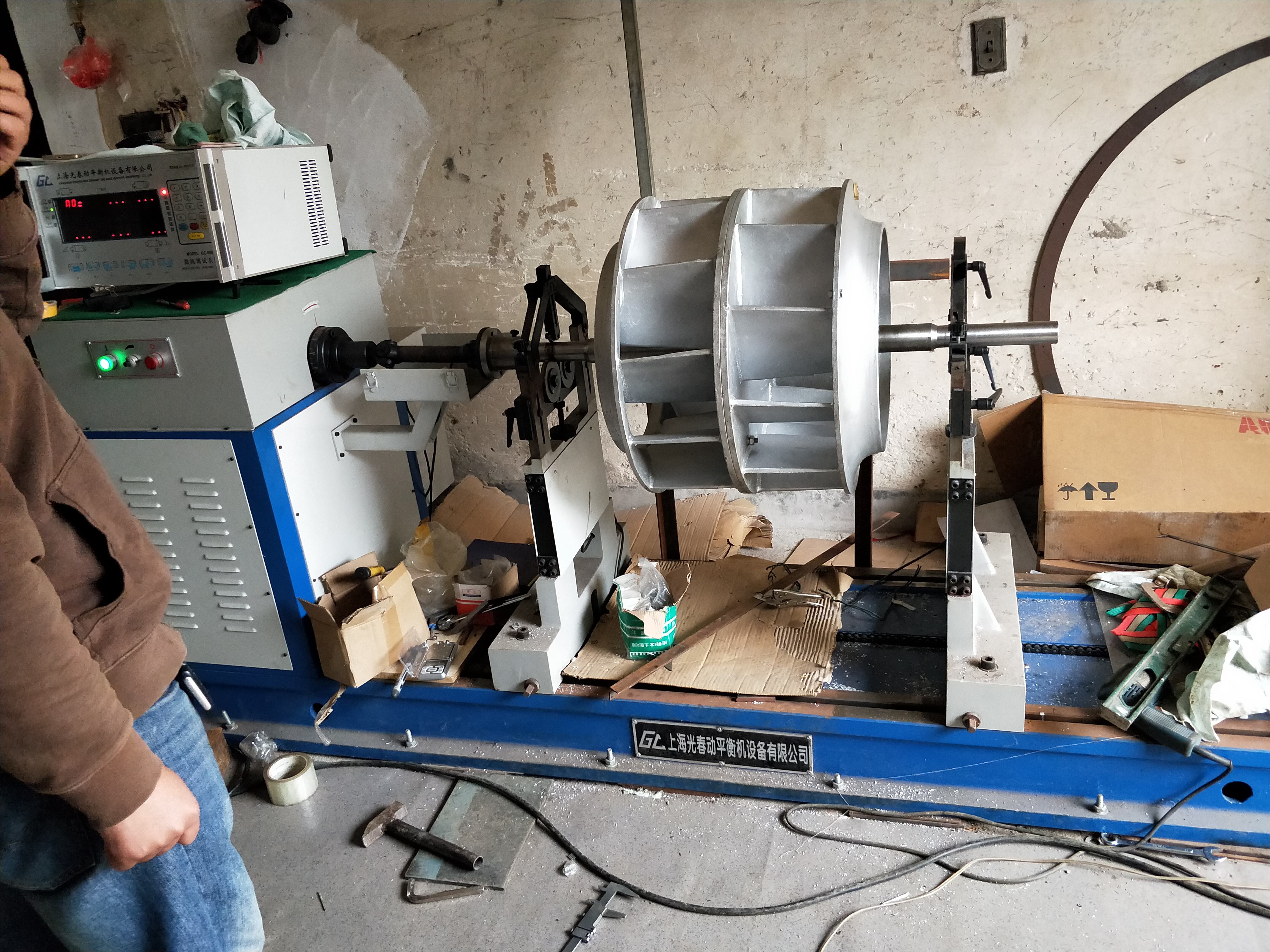

reliable balancing machine

A reliable balancing machine is a sophisticated piece of equipment designed to detect and correct imbalances in rotating components. This precision instrument utilizes advanced sensor technology and computerized analysis to measure vibration levels and identify the exact location and magnitude of imbalance. Operating through a combination of mechanical and electronic systems, these machines can handle various components ranging from small turbine rotors to large industrial equipment. The machine works by spinning the component at specific speeds while sensitive sensors measure the centrifugal forces generated by any imbalance. Through real-time data processing, it provides accurate measurements in both single and dual planes, enabling precise correction of imbalances. The technology incorporates automatic calibration features and user-friendly interfaces, making it accessible to both experienced technicians and newer operators. These machines are essential in manufacturing, maintenance, and quality control processes across numerous industries, including automotive, aerospace, power generation, and general manufacturing. They ensure optimal performance of rotating equipment, extend component lifespan, and prevent costly breakdowns due to vibration-related issues.