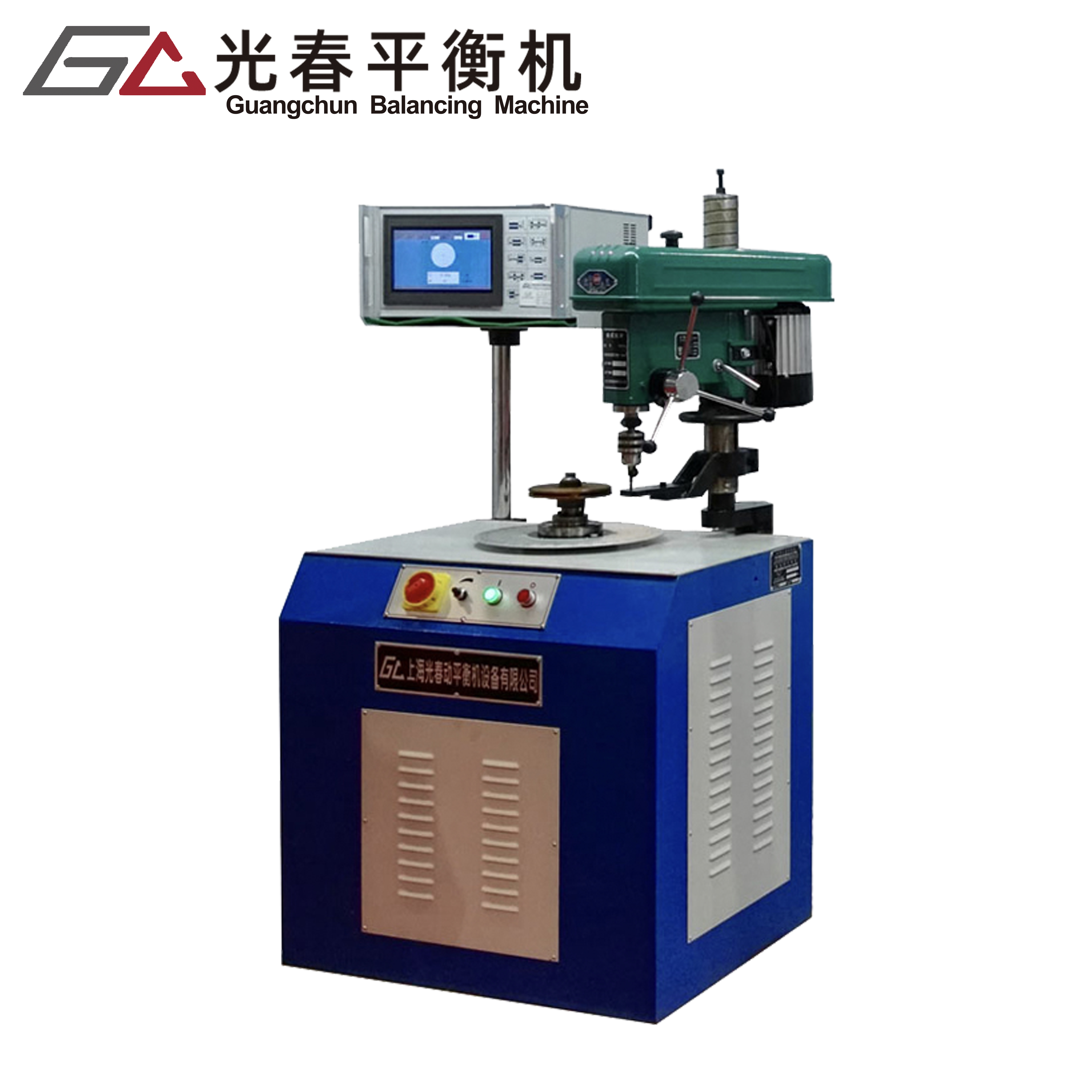

balance machine

A balance machine represents a sophisticated piece of precision equipment designed to detect and correct imbalances in rotating components. Operating through advanced sensors and digital processing systems, these machines measure dynamic and static imbalance with exceptional accuracy. The technology employs specialized algorithms to analyze vibration patterns and mass distribution across rotating parts, enabling precise identification of imbalance locations and magnitudes. Modern balance machines integrate smart features including automated measurement cycles, real-time data analysis, and computer-aided correction recommendations. They can handle components ranging from small turbine blades to large industrial rotors, accommodating various sizes and weights. The machine's measuring system typically consists of piezoelectric sensors, digital encoders, and high-speed processors that work in concert to deliver accurate readings. Applications span across numerous industries, including automotive manufacturing, aerospace components, power generation equipment, and precision machinery production. The system's ability to perform both single-plane and dual-plane balancing makes it versatile for different component types. These machines also feature calibration capabilities, ensuring sustained accuracy over time and maintaining measurement precision across multiple operating conditions.