heavyduty balancing equipment

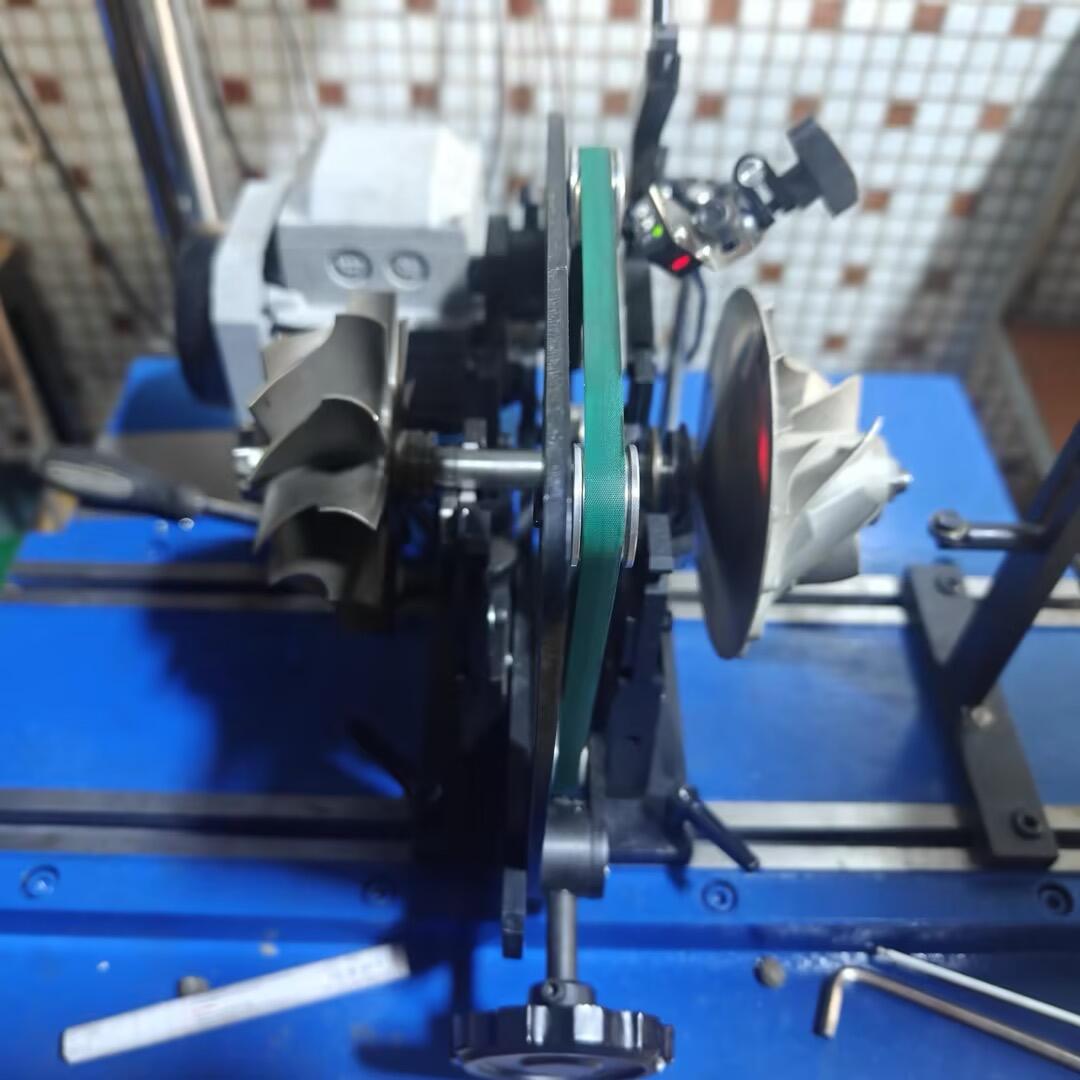

Heavy duty balancing equipment represents a crucial advancement in industrial machinery maintenance and operational efficiency. This sophisticated equipment is designed to handle large rotating components weighing up to several tons, ensuring optimal performance and longevity of industrial machinery. The system employs cutting-edge sensor technology and precision measurement capabilities to detect and correct imbalances in rotating equipment such as turbines, motors, rollers, and industrial fans. The equipment features advanced digital controls and real-time monitoring systems that provide accurate measurements down to micron levels. Its robust construction allows for both horizontal and vertical balancing operations, accommodating various component sizes and configurations. The system includes automated measurement processes that significantly reduce human error and increase accuracy in balance corrections. Additionally, it incorporates sophisticated software that analyzes vibration patterns and provides detailed reports for documentation and quality control purposes. The equipment's versatility extends to its ability to handle both single-plane and multi-plane balancing requirements, making it suitable for a wide range of industrial applications, from power generation to heavy manufacturing.