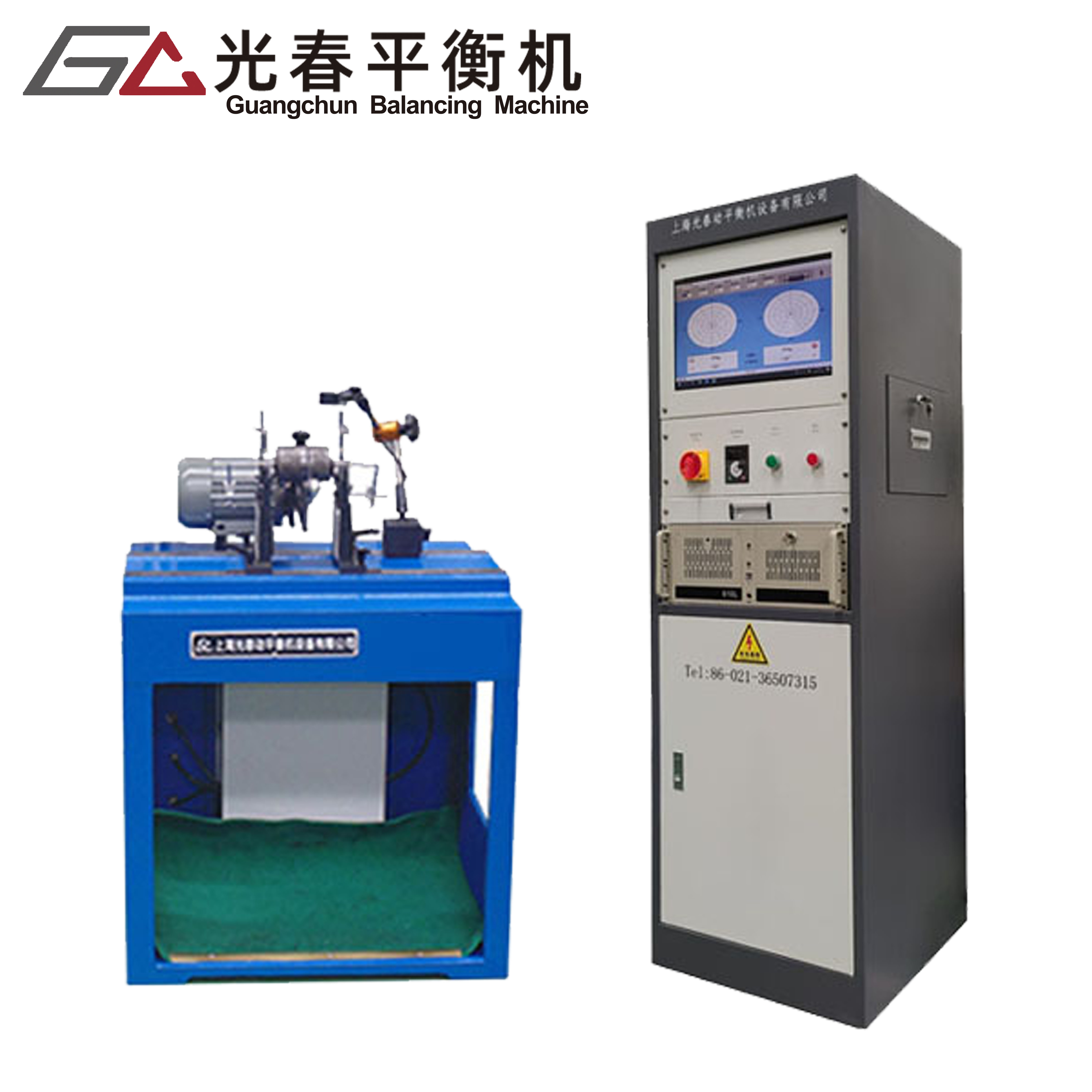

dynamic balancing machine supplier

A dynamic balancing machine supplier stands at the forefront of precision engineering, offering cutting-edge solutions for industrial balancing needs. These suppliers provide sophisticated equipment designed to detect and correct rotational imbalances in various mechanical components. Their machines utilize advanced sensor technology and computer-controlled systems to measure vibration patterns and calculate precise correction weights. The equipment can handle a wide range of components, from small turbine rotors to large industrial fans, ensuring optimal performance and longevity of rotating machinery. These suppliers typically offer comprehensive solutions that include not only the balancing machines but also technical support, calibration services, and maintenance programs. Their machines feature real-time monitoring capabilities, automated measuring cycles, and user-friendly interfaces that simplify the balancing process. The technology incorporates precision measuring sensors, advanced digital signal processing, and automated correction weight placement systems. These machines are essential in manufacturing sectors such as automotive, aerospace, power generation, and heavy industry, where balanced rotating components are crucial for operational efficiency and safety.