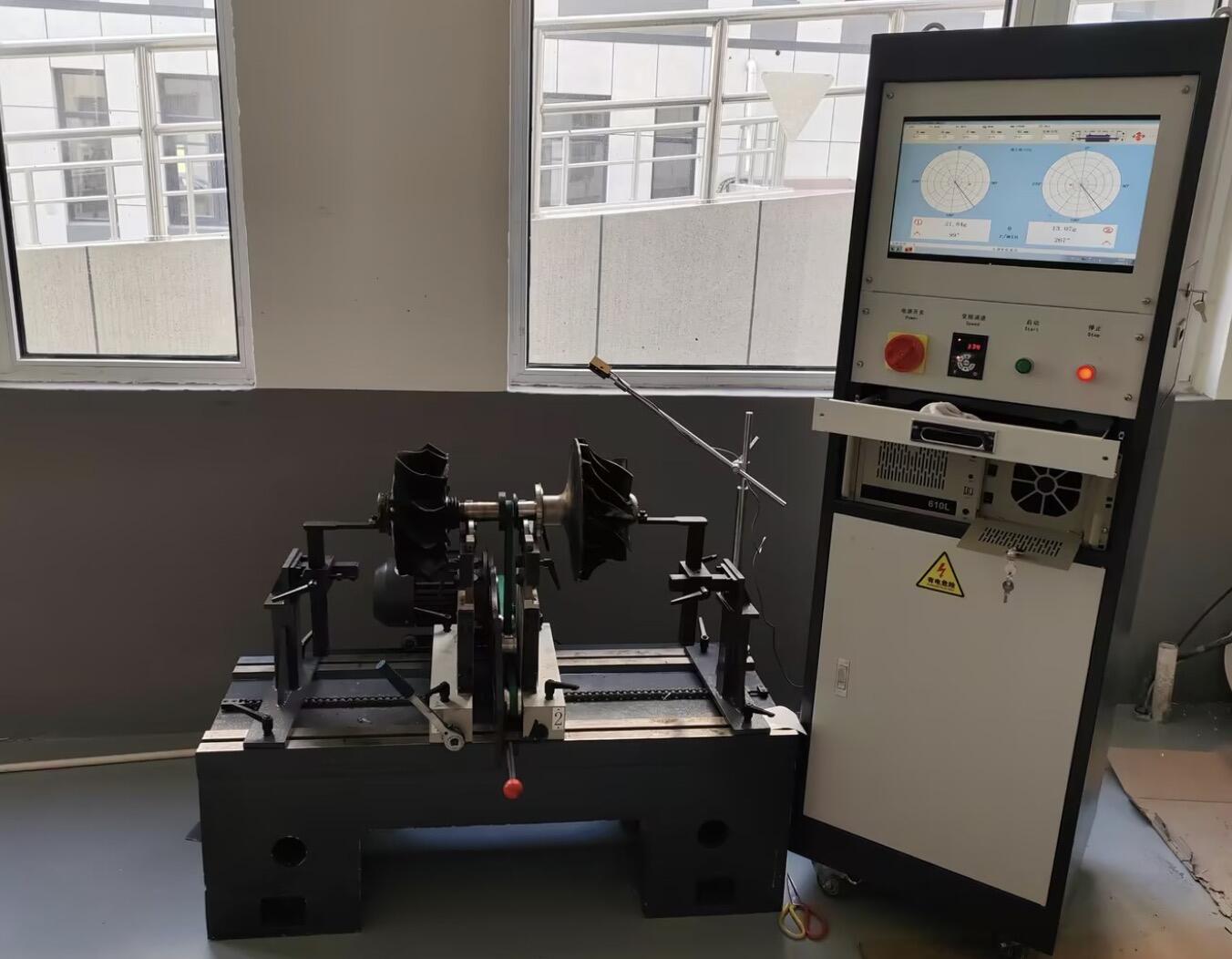

universal vertical balancing machine

The universal vertical balancing machine represents a pinnacle of precision engineering technology designed for dynamic balancing of rotary components. This sophisticated equipment operates by mounting workpieces vertically and measuring imbalance through advanced sensor systems. The machine employs high precision measuring instruments to detect both static and dynamic imbalances in rotating parts, offering accuracy levels down to 0.1 gram-millimeter. Its versatile design accommodates a wide range of components, from small turbine rotors to large industrial fans, with the capability to handle parts weighing from a few grams to several tons. The system utilizes computer-controlled operations to automatically calculate correction weights and positions, significantly reducing human error in the balancing process. Modern universal vertical balancing machines feature user friendly interfaces, real time data analysis, and automated correction suggestions. They incorporate vibration isolation systems to ensure accurate measurements regardless of environmental conditions. These machines are essential in manufacturing sectors where rotating equipment requires precise balance, such as automotive, aerospace, power generation, and general industrial applications. The technology enables manufacturers to achieve higher quality standards, reduce equipment wear, and extend the operational life of rotating components.