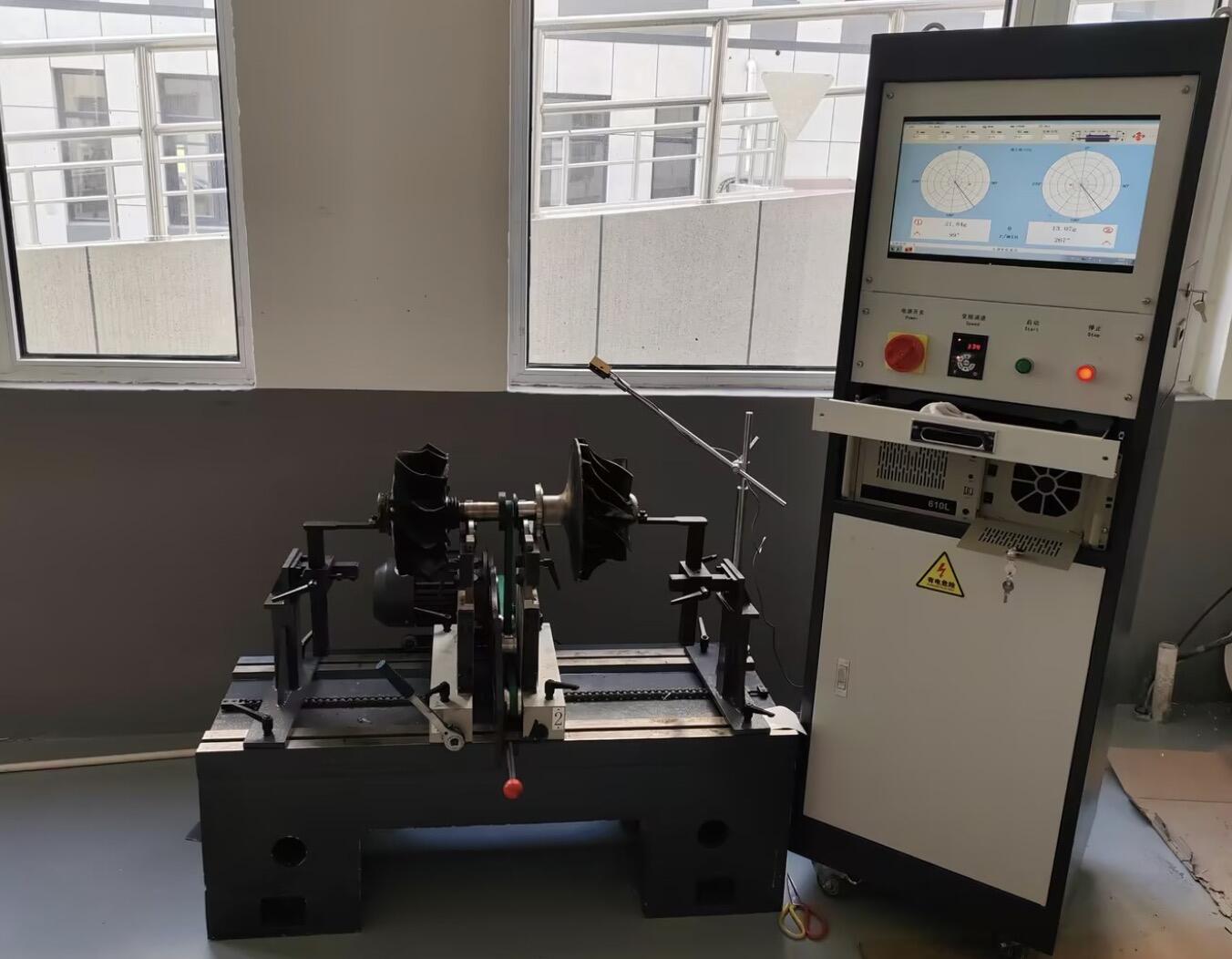

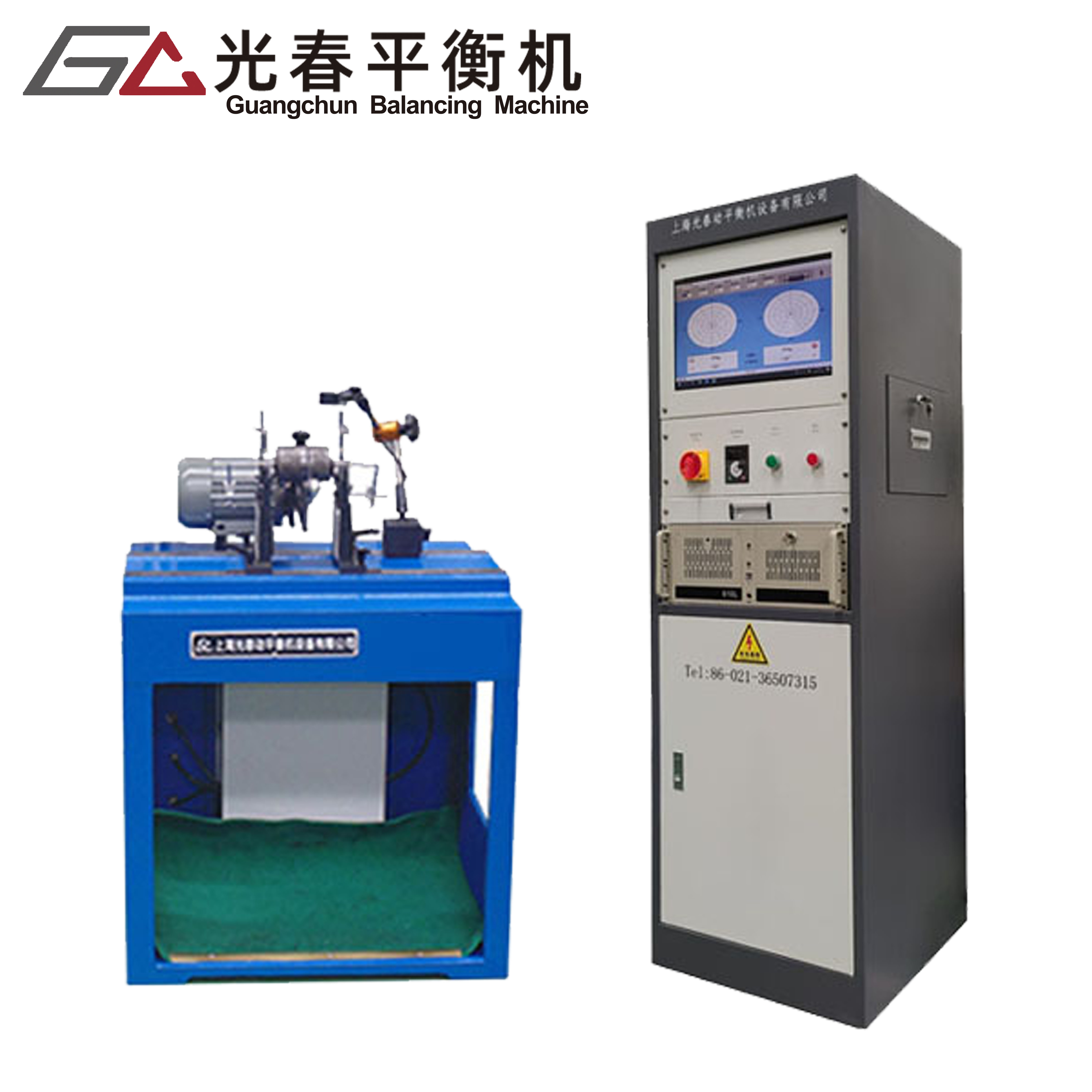

dynamic balancing machines

Dynamic balancing machines are sophisticated precision instruments designed to detect and correct rotational imbalances in various mechanical components. These machines operate by measuring the distribution of mass around a rotating axis, identifying areas where weight is unevenly distributed. Using advanced sensors and computerized analysis systems, they can detect even minimal imbalances that could lead to vibration, wear, and potential equipment failure. The technology employs both hard-mounted and soft-mounted systems, depending on the specific application requirements. Modern dynamic balancing machines feature high-resolution digital displays, automated measurement processes, and real-time data analysis capabilities. They are essential in manufacturing and maintenance operations across numerous industries, including automotive, aerospace, power generation, and industrial machinery. The machines can handle components ranging from small turbine rotors to large industrial fans, offering precise measurements in both single-plane and two-plane balancing operations. The integration of advanced software allows for detailed reporting, data storage, and trend analysis, enabling preventive maintenance strategies and quality control protocols. These machines significantly contribute to extending equipment life, reducing maintenance costs, and ensuring optimal performance of rotating machinery.