good balancing machine

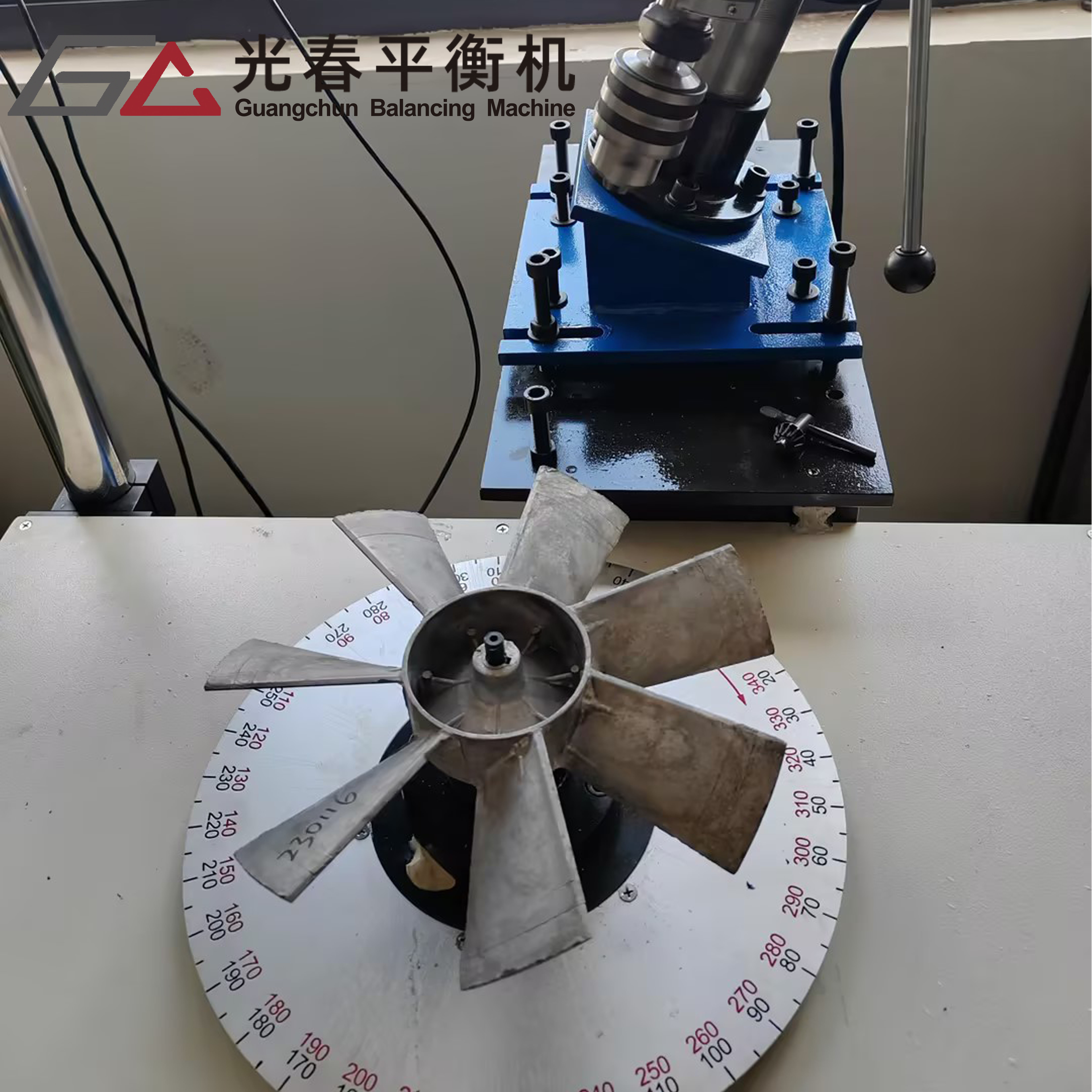

A good balancing machine is a precision instrument designed to detect and correct imbalances in rotating components. This sophisticated equipment utilizes advanced sensors and digital technology to measure vibration levels and identify the exact location and magnitude of imbalance in rotating parts. The machine operates by spinning the component at specific speeds while monitoring its behavior through multiple measuring points. Modern balancing machines feature high-resolution displays, intuitive software interfaces, and automatic calculation capabilities that provide real-time analysis of imbalance conditions. They can handle various component sizes, from small rotors to large industrial machinery parts, with exceptional accuracy down to micrometers. The technology incorporates multiple measurement planes for both static and dynamic balancing, ensuring comprehensive analysis of the workpiece. These machines are equipped with self-calibrating systems, automatic compensation for measurement errors, and built-in quality control parameters. Applications span across numerous industries, including automotive manufacturing, aerospace components, power generation equipment, and precision machinery production. The balancing process is essential for ensuring optimal performance, reducing wear and tear, minimizing vibration-related issues, and extending the operational lifespan of rotating equipment.