balancing machines

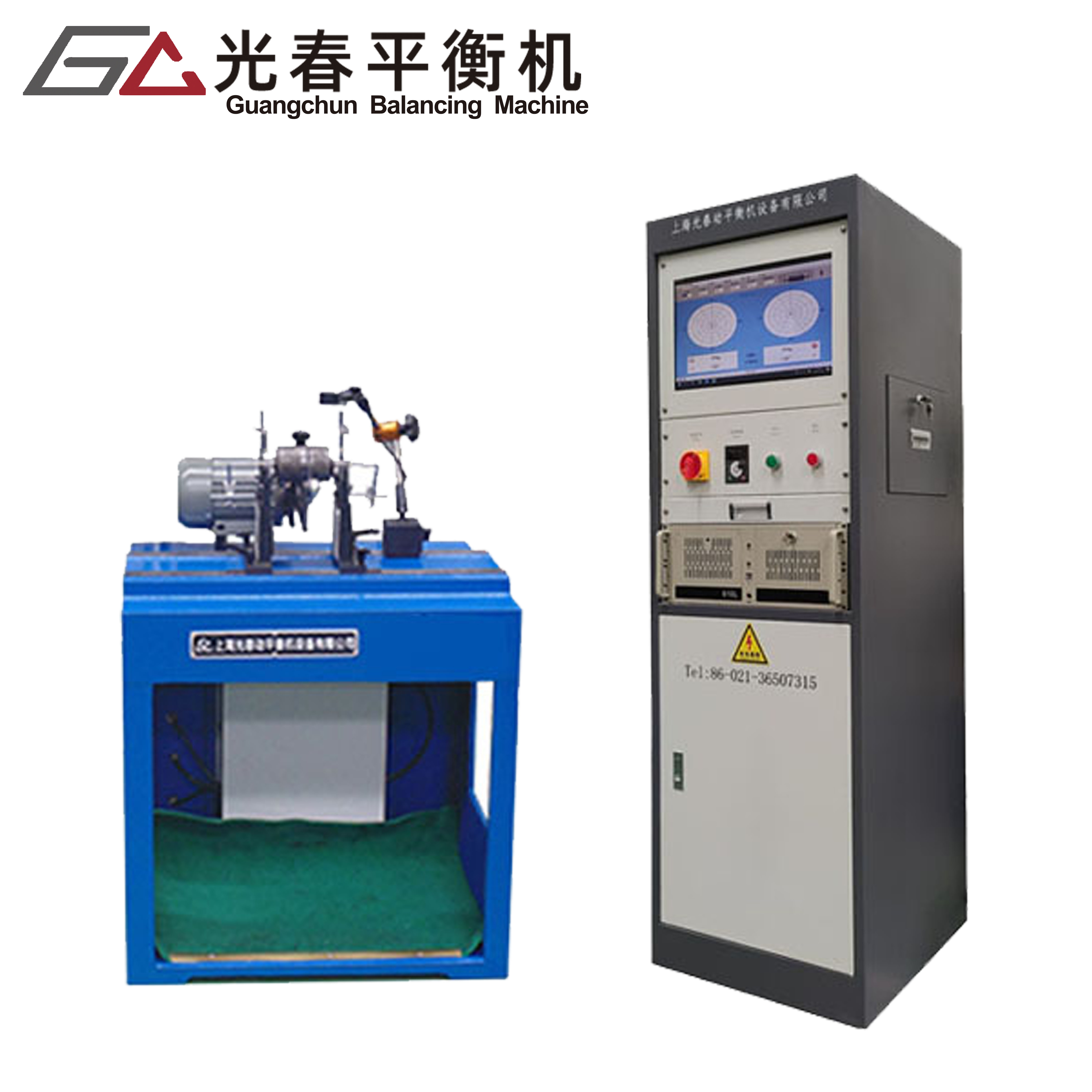

Balancing machines represent cutting-edge precision equipment designed to detect and correct rotational imbalances in various mechanical components. These sophisticated devices utilize advanced sensors and computerized analysis to measure the distribution of mass in rotating parts, ensuring optimal performance and longevity of industrial machinery. The machines operate by spinning the component at specific speeds while sensitive measuring systems detect any variations in centrifugal forces, which indicate imbalance. Modern balancing machines incorporate digital technology, offering real-time data analysis and automated correction recommendations. They can handle components ranging from tiny turbine blades to massive industrial rotors, making them essential in industries such as automotive manufacturing, aerospace, power generation, and general manufacturing. The machines feature user-friendly interfaces that guide operators through the balancing process, providing clear visual feedback and detailed reports. Their precision capabilities extend to measuring imbalances as minute as a fraction of a gram-millimeter, ensuring the highest standards of quality control.