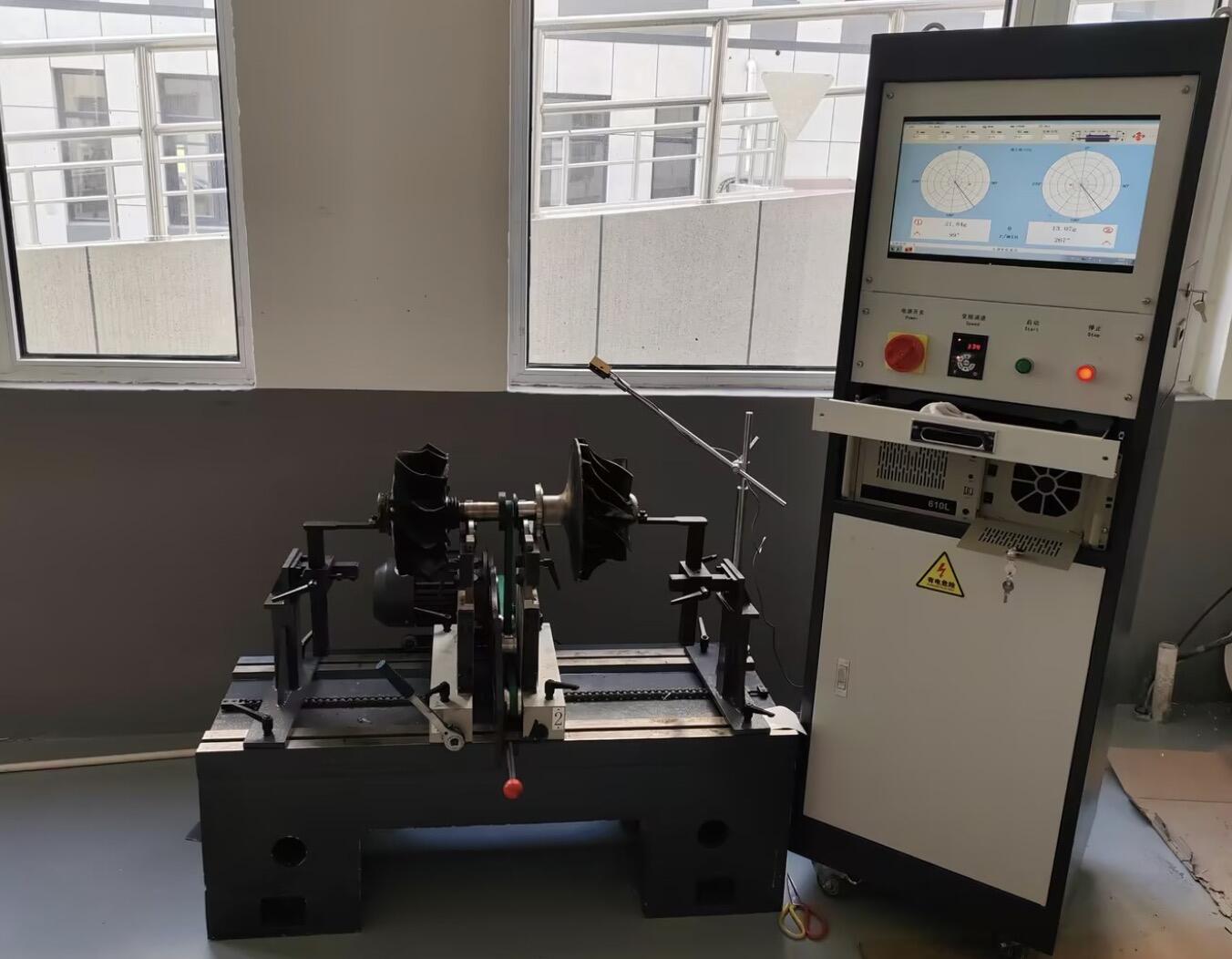

tool balancing machine

A tool balancing machine is an essential piece of precision equipment designed to measure and correct imbalances in rotating tools and components. This sophisticated device utilizes advanced sensors and digital technology to detect even minute vibrations and weight distributions that could affect tool performance. Operating through high-speed rotation analysis, the machine measures both static and dynamic imbalance, providing real-time data on the exact location and magnitude of any irregularities. The system employs laser measurement technology and sophisticated software algorithms to ensure accuracy down to microscopic levels. These machines are particularly valuable in manufacturing environments where tool precision directly impacts product quality. They can handle a wide range of tools, from small cutting instruments to large industrial components, with maximum rotation speeds typically reaching up to 3000 RPM. The balancing process involves mounting the tool on a specialized spindle, running it through multiple test cycles, and automatically calculating the necessary weight adjustments. Modern tool balancing machines often feature user-friendly interfaces with touchscreen controls and automated calibration systems, making them accessible to operators of varying skill levels.