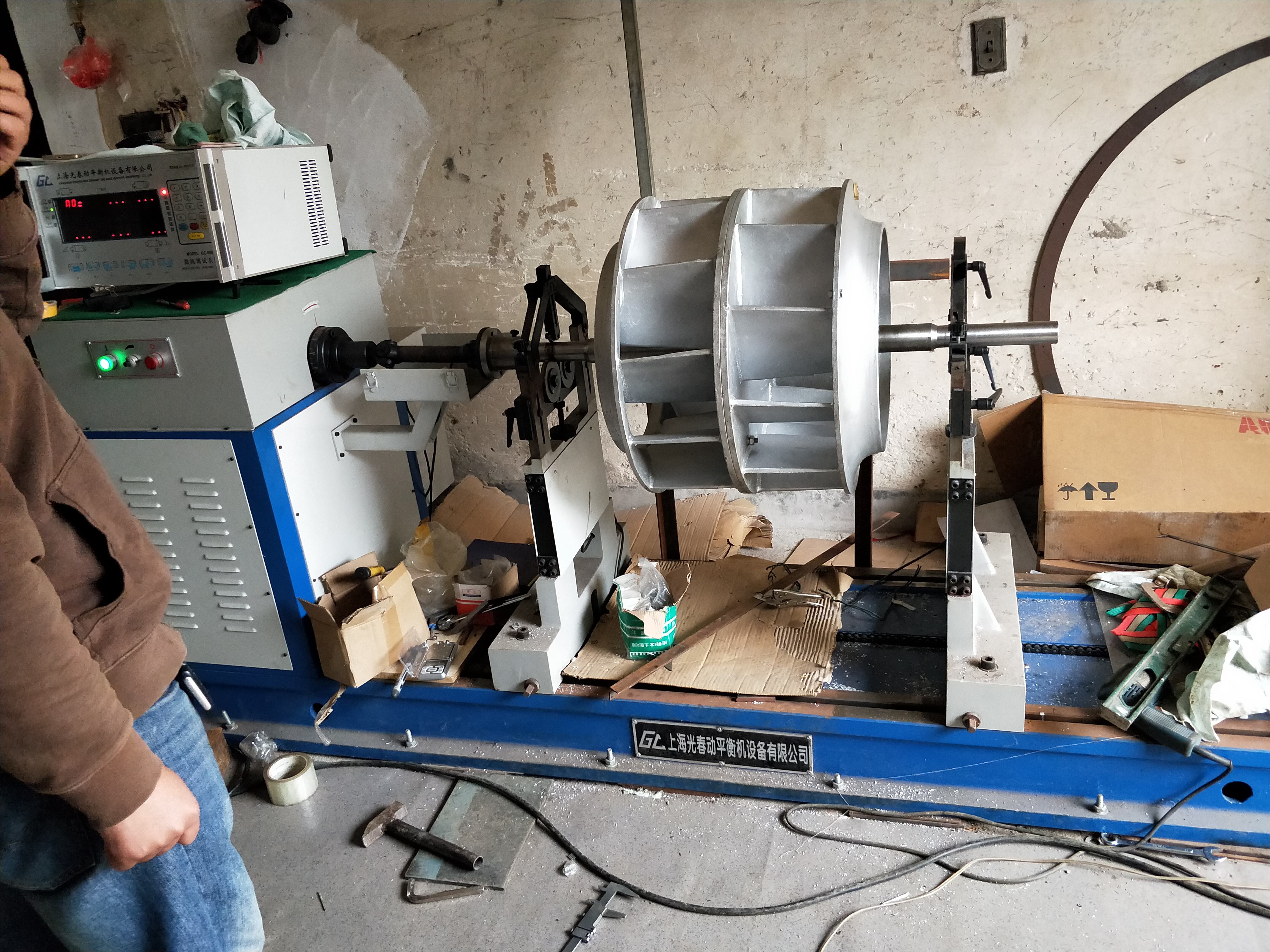

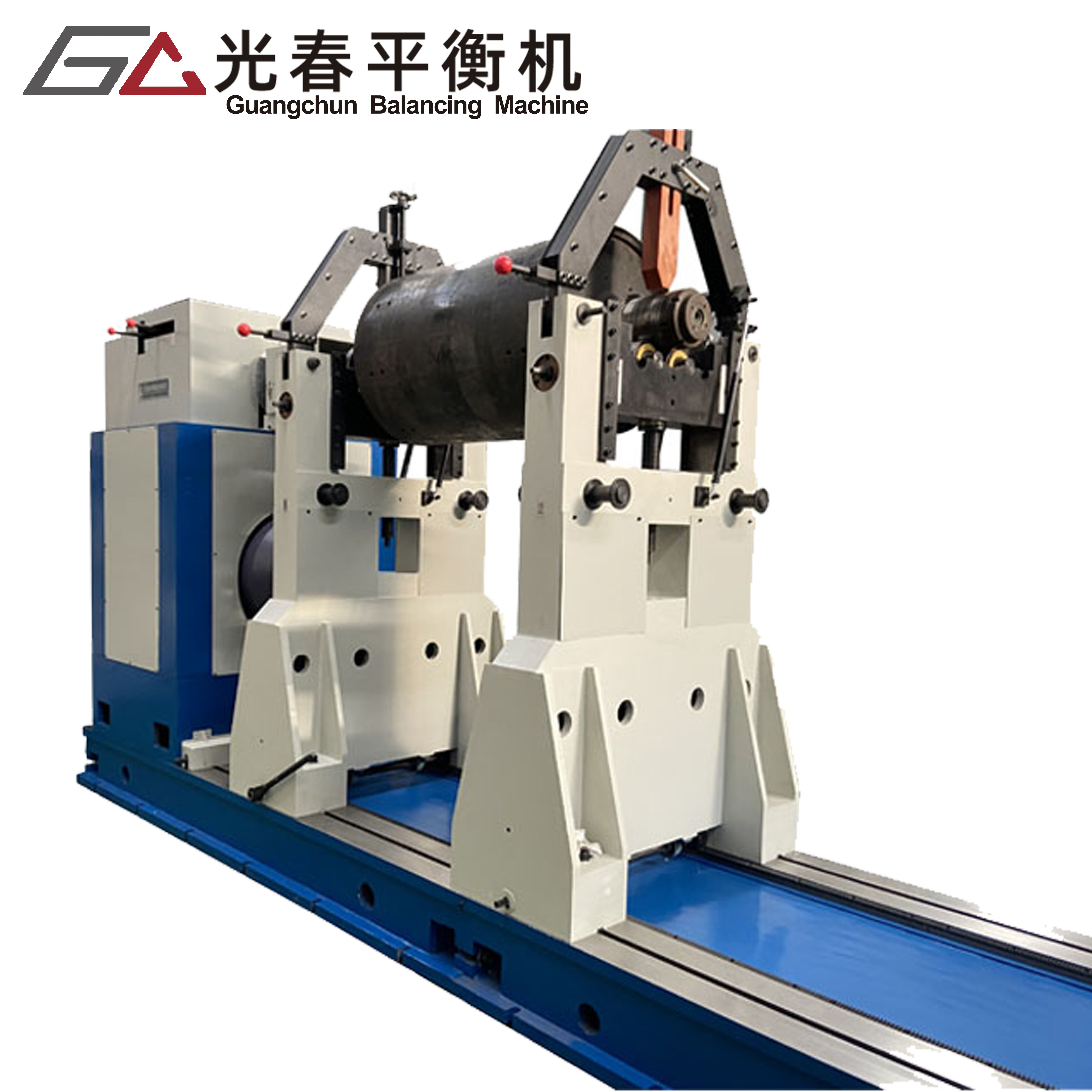

high quality balance machine

A high quality balance machine represents the pinnacle of precision engineering technology, designed to deliver exceptional accuracy in measuring and correcting rotational imbalance in various mechanical components. This sophisticated equipment utilizes advanced sensors and digital processing capabilities to detect even the slightest irregularities in rotating parts. The machine operates by spinning the component at specific speeds while highly sensitive measuring units detect and analyze vibration patterns. Through complex algorithms, it precisely identifies the location and magnitude of imbalance, enabling operators to make necessary corrections with pinpoint accuracy. The machine's versatility allows it to handle a wide range of components, from small turbine rotors to large industrial fans, making it an essential tool across multiple industries. Its user-friendly interface simplifies operation while maintaining professional-grade accuracy, featuring real-time monitoring and automatic calculation of correction weights. The integration of modern digital technology enables data logging and analysis capabilities, allowing for quality control documentation and trend analysis. Safety features include automatic emergency stops and protective enclosures, ensuring operator safety during high-speed operations. The machine's robust construction ensures long-term reliability and consistent performance, while its modular design facilitates maintenance and upgrades.