what is the dynamic balancing

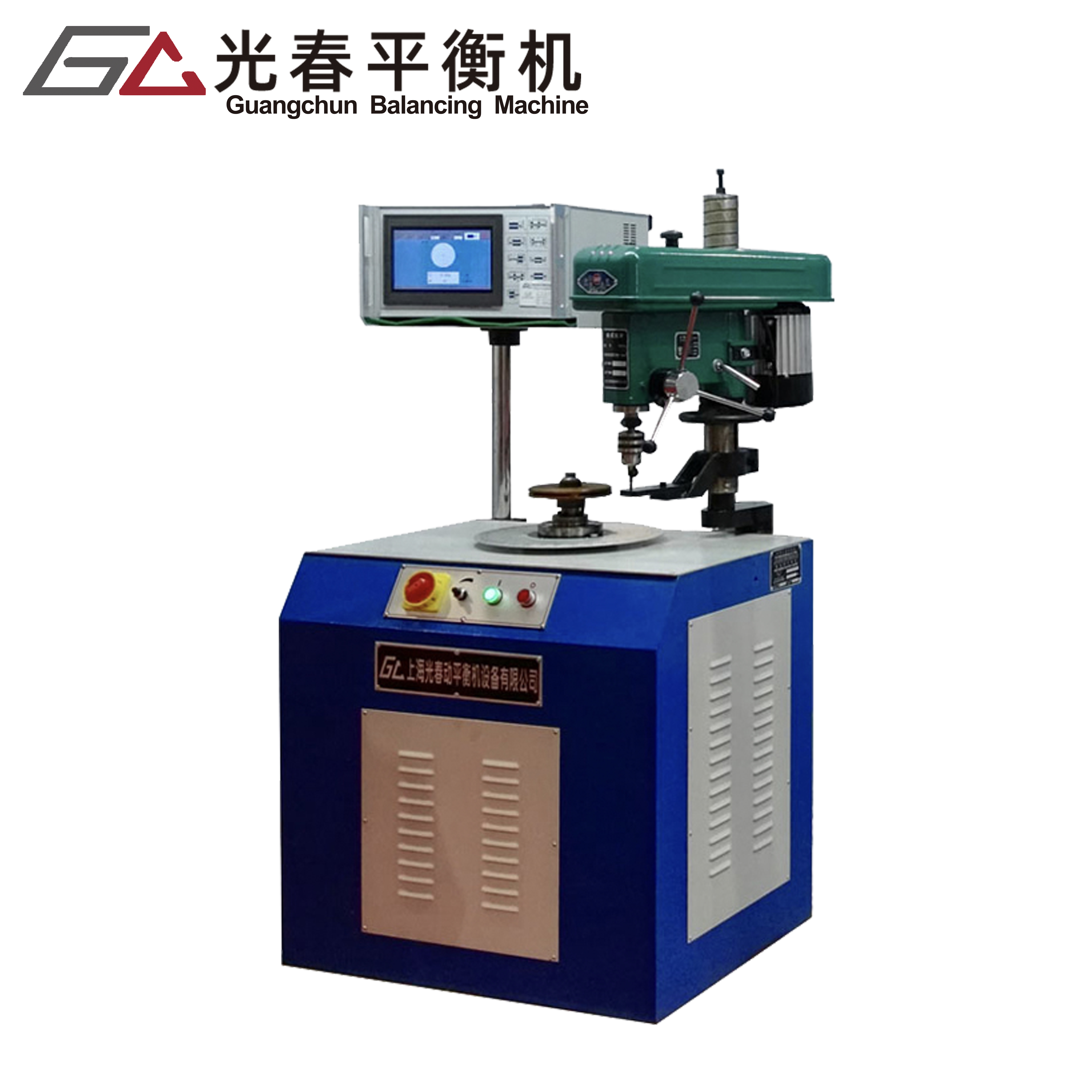

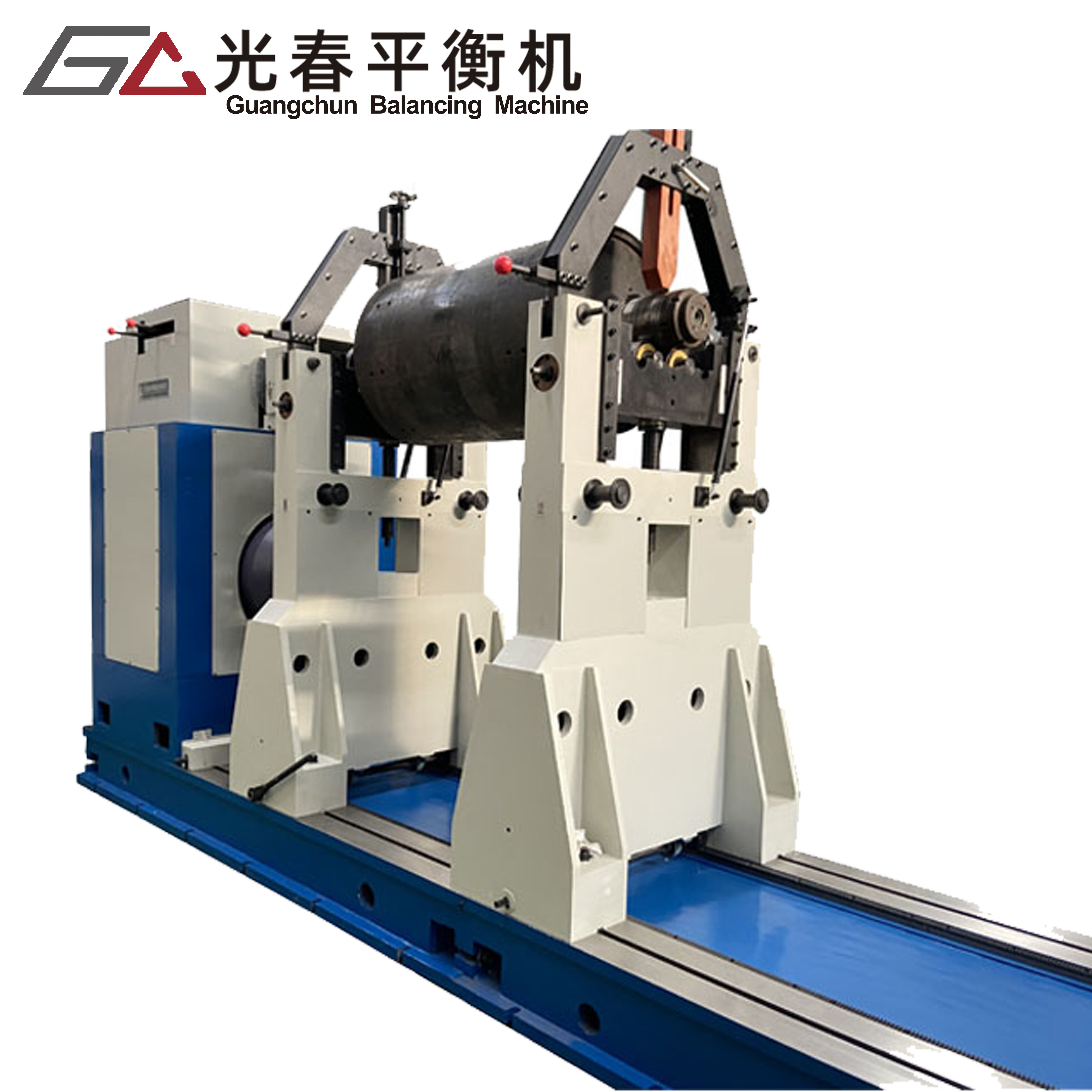

Dynamic balancing is a critical process in mechanical engineering that ensures rotating machinery operates smoothly and efficiently. This sophisticated technique involves the measurement and correction of rotational imbalances in mechanical components, such as rotors, fans, turbines, and other rotating equipment. The process works by identifying the distribution of mass around an axis of rotation and making precise adjustments to achieve optimal balance. Using advanced sensors and computerized equipment, dynamic balancing systems detect vibrations and measure the magnitude and location of unbalance forces. These measurements are then analyzed to determine where corrective weights should be added or removed to achieve equilibrium. The technology has evolved significantly, incorporating real-time monitoring capabilities and automated correction systems that can maintain balance during operation. Dynamic balancing is essential in various industries, including automotive manufacturing, aerospace, power generation, and industrial equipment production. It plays a crucial role in preventing premature wear, reducing energy consumption, minimizing noise levels, and extending equipment lifespan. Modern dynamic balancing systems can achieve precision levels down to micrometers, ensuring optimal performance in high-speed applications where even minimal imbalance can cause significant issues.