The industrial machinery sector continues to evolve with technological advancements, and general balancing machines remain at the forefront of precision manufacturing operations. These sophisticated systems are essential for ensuring optimal performance across various rotating equipment applications, from automotive components to aerospace assemblies. Manufacturing facilities worldwide depend on reliable balancing solutions to maintain product quality, reduce operational downtime, and meet stringent industry standards.

The selection process for general balancing machines requires careful consideration of multiple factors, including capacity requirements, accuracy specifications, and operational environments. Modern facilities seek equipment that offers versatility, precision, and long-term reliability while providing excellent return on investment. Understanding the key features and capabilities of contemporary balancing systems enables procurement teams to make informed decisions that support their operational objectives and quality requirements.

Essential Features of Modern General Balancing Machines

Advanced Sensor Technology and Measurement Accuracy

Contemporary general balancing machines incorporate state-of-the-art sensor systems that deliver exceptional measurement precision across diverse applications. These sensors utilize advanced piezoelectric technology and sophisticated signal processing algorithms to detect even minimal unbalance conditions in rotating components. The integration of multiple sensor configurations allows for comprehensive analysis of both static and dynamic unbalance conditions, ensuring thorough evaluation of workpiece characteristics.

The measurement accuracy of modern systems typically ranges from 0.1 to 0.01 gmm per kilogram, depending on the specific machine configuration and application requirements. This level of precision enables manufacturers to achieve stringent quality standards while maintaining efficient production rates. Advanced calibration procedures and automated compensation features further enhance measurement reliability, reducing operator dependency and minimizing potential human error factors.

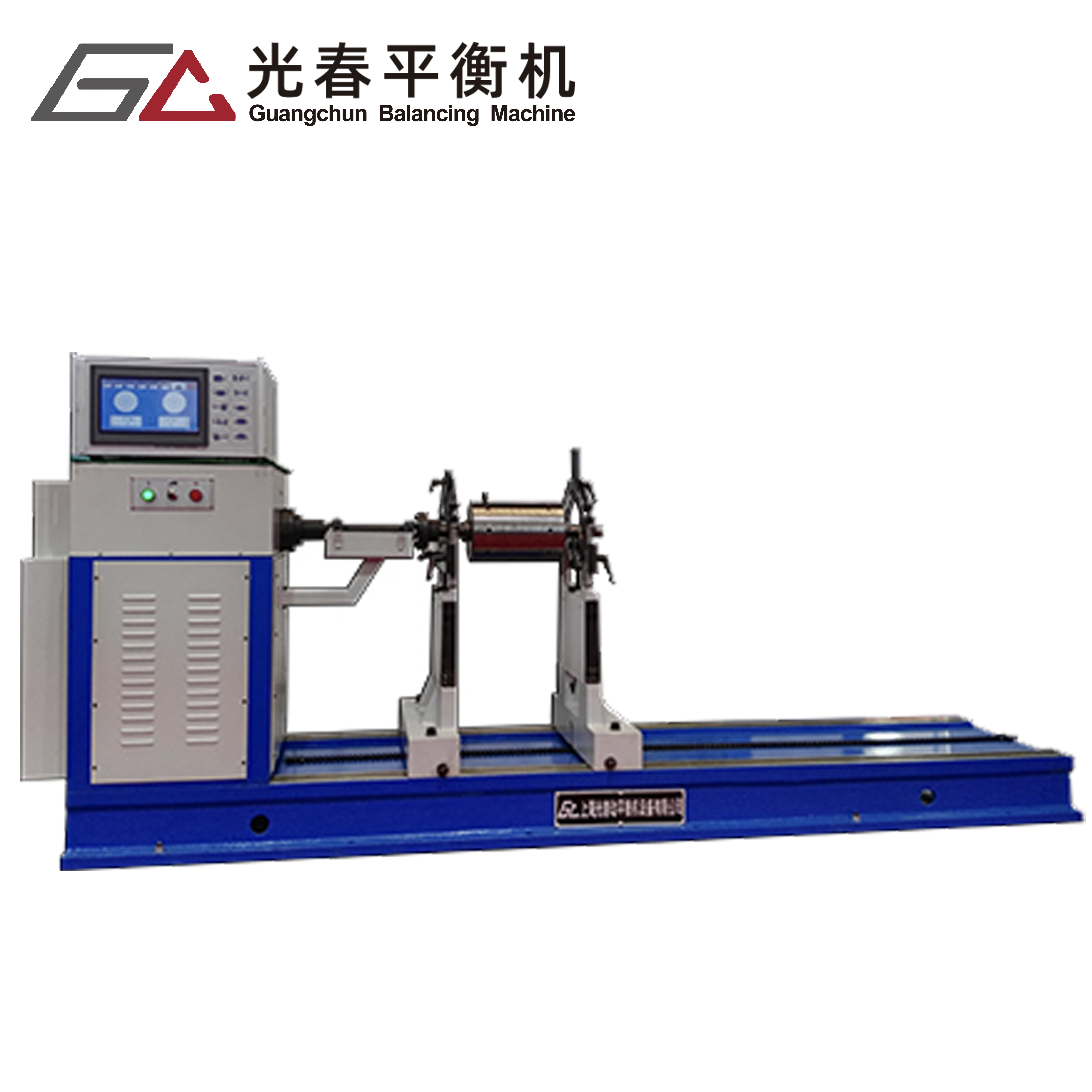

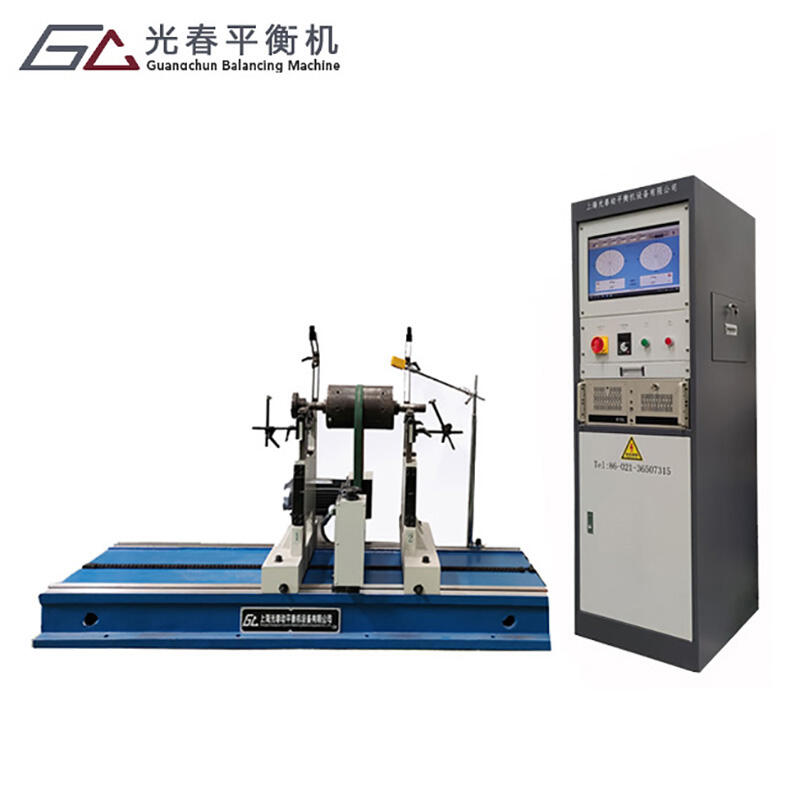

Versatile Workpiece Handling Systems

Flexibility in workpiece accommodation represents a critical advantage of high-quality general balancing machines. Modern systems feature adjustable support structures, variable-speed drives, and adaptable tooling configurations that accommodate diverse component geometries and weight ranges. These capabilities enable facilities to process multiple product lines using a single balancing system, maximizing equipment utilization and operational efficiency.

Automated loading and unloading mechanisms further enhance operational productivity by reducing cycle times and minimizing manual handling requirements. Pneumatic and servo-driven positioning systems ensure consistent workpiece placement while maintaining operator safety standards. Integration with existing production line automation systems allows for seamless workflow management and enhanced overall manufacturing efficiency.

Performance Specifications and Capacity Considerations

Weight and Size Range Capabilities

The capacity specifications of general balancing machines vary significantly based on intended applications and target market segments. Entry-level systems typically accommodate components weighing from 0.1 to 50 kilograms, while heavy-duty industrial models can handle workpieces exceeding 1000 kilograms. Diameter capabilities range from small precision components measuring just a few centimeters to large assemblies spanning several meters in diameter.

Selection of appropriate capacity specifications requires careful analysis of current and anticipated future production requirements. Oversizing equipment may result in unnecessary capital expenditure and reduced measurement accuracy for smaller components, while undersizing limits operational flexibility and growth potential. Experienced manufacturers often recommend selecting systems with 20-30% capacity buffer to accommodate future product developments and unexpected requirements.

Speed Range and Dynamic Performance

Operating speed ranges represent another crucial specification for general balancing machines, as different applications require specific rotational velocities for optimal measurement accuracy. Low-speed applications, typically ranging from 100 to 1000 RPM, are suitable for large, heavy components where structural limitations prevent high-speed operation. High-speed configurations, operating between 3000 and 10000 RPM, enable precise measurement of smaller components and dynamic unbalance conditions.

Variable frequency drive systems provide precise speed control and smooth acceleration profiles, ensuring measurement repeatability and extending equipment service life. Advanced vibration isolation systems minimize external interference and maintain measurement accuracy across the entire speed range. These features contribute significantly to overall system performance and measurement reliability in challenging industrial environments.

Technology Integration and Software Capabilities

Digital Control Systems and User Interfaces

Modern general balancing machines feature sophisticated digital control systems that streamline operation procedures and enhance measurement capabilities. Intuitive touchscreen interfaces provide operators with real-time feedback, comprehensive data visualization, and simplified control functions. These systems typically include pre-programmed balancing procedures for common applications, reducing setup time and minimizing operator training requirements.

Advanced software packages offer extensive data logging capabilities, statistical process control features, and comprehensive reporting functions. Integration with enterprise resource planning systems enables seamless data flow and supports quality management initiatives. Cloud-based connectivity options provide remote monitoring capabilities and predictive maintenance features that enhance operational reliability and reduce unplanned downtime.

Quality Management and Traceability Features

Comprehensive quality management capabilities distinguish premium general balancing machines from basic measurement systems. Advanced software platforms provide complete traceability functions, including workpiece identification, measurement results, correction procedures, and operator information. These features support ISO certification requirements and enable detailed quality audits when required by customer specifications or regulatory standards.

Statistical process control modules analyze measurement trends, identify potential quality issues, and provide early warning indicators for preventive maintenance activities. Automated acceptance criteria evaluation ensures consistent quality standards while reducing operator decision-making requirements. Integration with barcode and RFID systems enables automated workpiece identification and reduces potential data entry errors.

Installation Requirements and Operational Considerations

Foundation and Environmental Specifications

Proper installation of general balancing machines requires careful attention to foundation requirements and environmental conditions. Vibration isolation systems demand stable, level foundations constructed from reinforced concrete or steel structures capable of supporting equipment weight and operational forces. Foundation specifications typically require thickness of 1.5 to 2 times the machine base dimensions, with appropriate anchor bolt configurations for secure equipment mounting.

Environmental factors including temperature stability, humidity control, and vibration isolation significantly impact measurement accuracy and equipment longevity. Climate-controlled installations maintain consistent operating conditions while protecting sensitive electronic components from temperature fluctuations. Proper electrical grounding and electromagnetic interference shielding ensure reliable operation in industrial environments with heavy electrical equipment and high-frequency interference sources.

Maintenance Requirements and Service Considerations

Routine maintenance procedures for general balancing machines include periodic calibration verification, sensor cleaning, mechanical component inspection, and software updates. Preventive maintenance schedules typically recommend daily operational checks, weekly cleaning procedures, monthly calibration verification, and annual comprehensive inspections. Following manufacturer-recommended maintenance protocols ensures consistent performance and extends equipment service life significantly.

Service support availability represents a critical factor in equipment selection, particularly for facilities operating multiple shifts or continuous production schedules. Comprehensive service agreements including remote diagnostic capabilities, expedited parts delivery, and on-site technical support minimize potential downtime impacts. Training programs for maintenance personnel enable internal capability development and reduce dependency on external service providers for routine maintenance activities.

Cost Analysis and Return on Investment

Initial Investment and Total Cost of Ownership

The initial investment for general balancing machines varies considerably based on capacity requirements, accuracy specifications, and included features. Entry-level systems suitable for small-scale operations typically range from $50,000 to $150,000, while high-capacity industrial systems can exceed $500,000 including installation and commissioning costs. Additional expenses including foundation preparation, electrical installation, and operator training should be incorporated into total project budgets.

Total cost of ownership calculations must consider ongoing operational expenses including maintenance costs, calibration requirements, and potential productivity improvements. Energy consumption, typically ranging from 5 to 25 kilowatts depending on system size, represents a minor operational expense compared to labor savings and quality improvements. Comprehensive financial analysis should evaluate payback periods based on reduced scrap rates, improved production efficiency, and enhanced product quality metrics.

Productivity Benefits and Quality Improvements

Implementation of modern general balancing machines typically results in significant productivity improvements through reduced cycle times, automated operation procedures, and enhanced measurement accuracy. Automated correction calculations eliminate manual calculation requirements while reducing potential operator errors. Integration with production management systems enables real-time monitoring and optimization of manufacturing processes.

Quality improvements achieved through precision balancing procedures contribute substantially to overall customer satisfaction and warranty cost reduction. Reduced vibration levels in balanced components extend service life, improve performance characteristics, and minimize maintenance requirements in end-use applications. These benefits often justify equipment investments through improved customer relationships and reduced field service costs.

Selecting the Right General Balancing Machine

Application-Specific Requirements Assessment

Successful selection of general balancing machines requires comprehensive analysis of specific application requirements, production volumes, and quality specifications. Different industries present unique challenges including automotive crankshafts requiring high-speed capability, aerospace components demanding exceptional accuracy, and electric motor rotors needing automated handling systems. Understanding these requirements enables informed equipment selection that optimizes performance and investment returns.

Consultation with experienced application engineers provides valuable insights into equipment capabilities and potential implementation challenges. Demonstration opportunities allow evaluation of actual performance characteristics using representative workpieces under realistic operating conditions. These evaluations help identify potential issues and validate equipment suitability before finalizing purchase decisions.

Vendor Selection and Support Capabilities

Choosing the appropriate vendor for general balancing machines involves evaluating technical expertise, service capabilities, and long-term support commitments. Established manufacturers with extensive application experience typically provide superior technical support and proven reliability records. Local service availability reduces response times and minimizes potential downtime impacts during equipment issues or routine maintenance activities.

Comprehensive warranty coverage and service agreements provide additional value through predictable maintenance costs and guaranteed performance levels. Training programs for operators and maintenance personnel ensure optimal equipment utilization and extend service life through proper operational procedures. Ongoing technical support including software updates and application assistance maintains equipment capability throughout its operational lifetime.

Future Trends and Technology Developments

Industry 4.0 Integration and Smart Manufacturing

The evolution of general balancing machines continues with increasing integration of Industry 4.0 technologies including artificial intelligence, machine learning, and advanced data analytics. These capabilities enable predictive maintenance scheduling, automated quality optimization, and comprehensive production monitoring. Smart manufacturing initiatives leverage real-time data collection and analysis to optimize balancing procedures and improve overall operational efficiency.

Internet of Things connectivity enables remote monitoring capabilities and cloud-based data storage for comprehensive production analysis. Advanced analytics platforms identify optimization opportunities and provide recommendations for improved performance. These developments represent the future direction of balancing technology and offer significant competitive advantages for early adopters in manufacturing operations.

Emerging Technologies and Innovation Opportunities

Continued technological advancement in sensor technology, signal processing, and automation systems promises further improvements in general balancing machines capabilities. Enhanced measurement accuracy, reduced cycle times, and improved automation levels will continue driving productivity improvements across diverse manufacturing applications. Integration with robotic systems and automated material handling equipment represents significant growth opportunities for comprehensive production line optimization.

Sustainability considerations including energy efficiency improvements and reduced material waste contribute to overall operational cost reduction and environmental responsibility. Advanced materials and manufacturing techniques enable more precise, durable equipment components that extend service life and reduce maintenance requirements. These innovations support long-term cost reduction and operational efficiency improvements for manufacturing facilities.

FAQ

What factors should be considered when selecting general balancing machines for automotive applications

Automotive applications require general balancing machines with specific capabilities including high-speed operation for crankshafts and flywheels, automated handling systems for high-volume production, and precision measurement accuracy for quality standards compliance. Consider weight capacity ranging from 5 to 200 kilograms, speed capabilities up to 5000 RPM, and integration with existing production line automation systems for optimal efficiency.

How often do general balancing machines require calibration and maintenance

General balancing machines typically require daily operational checks, weekly cleaning procedures, monthly calibration verification using certified reference standards, and comprehensive annual inspections including sensor calibration and mechanical component evaluation. Actual requirements may vary based on operating conditions, production volumes, and manufacturer specifications. Regular maintenance ensures consistent accuracy and extends equipment service life significantly.

What is the typical accuracy range for modern general balancing machines

Modern general balancing machines achieve measurement accuracy ranging from 0.1 gmm/kg for standard industrial applications to 0.01 gmm/kg for precision applications requiring exceptional accuracy. Actual accuracy depends on factors including machine design, sensor technology, operating environment, and workpiece characteristics. Higher accuracy levels typically require more sophisticated equipment and controlled operating conditions.

Can general balancing machines be integrated with existing production management systems

Yes, modern general balancing machines feature comprehensive connectivity options including Ethernet, USB, and wireless interfaces that enable integration with enterprise resource planning systems, quality management software, and production monitoring platforms. This integration provides real-time data collection, automated reporting capabilities, and comprehensive traceability functions that support quality management initiatives and operational efficiency improvements.

Table of Contents

- Essential Features of Modern General Balancing Machines

- Performance Specifications and Capacity Considerations

- Technology Integration and Software Capabilities

- Installation Requirements and Operational Considerations

- Cost Analysis and Return on Investment

- Selecting the Right General Balancing Machine

- Future Trends and Technology Developments

-

FAQ

- What factors should be considered when selecting general balancing machines for automotive applications

- How often do general balancing machines require calibration and maintenance

- What is the typical accuracy range for modern general balancing machines

- Can general balancing machines be integrated with existing production management systems