Understanding Modern Crankshaft Balancing Technology

The evolution of automotive engineering has placed unprecedented demands on engine performance and efficiency. At the heart of this advancement lies the critical role of crankshaft balancing machines, sophisticated equipment that ensures optimal engine operation through precise measurement and correction of rotational imbalances. These specialized machines have become indispensable tools in both manufacturing and maintenance operations, contributing significantly to engine longevity and performance.

Today's crankshaft balancing machines incorporate cutting-edge sensors and computational systems that can detect even microscopic imbalances. This precision is essential for modern high-performance engines, where even slight irregularities can lead to vibration, reduced efficiency, and premature wear. The technology continues to evolve, offering enhanced features that make the balancing process more accurate and efficient than ever before.

Essential Features of Premium Balancing Equipment

Advanced Measurement Systems

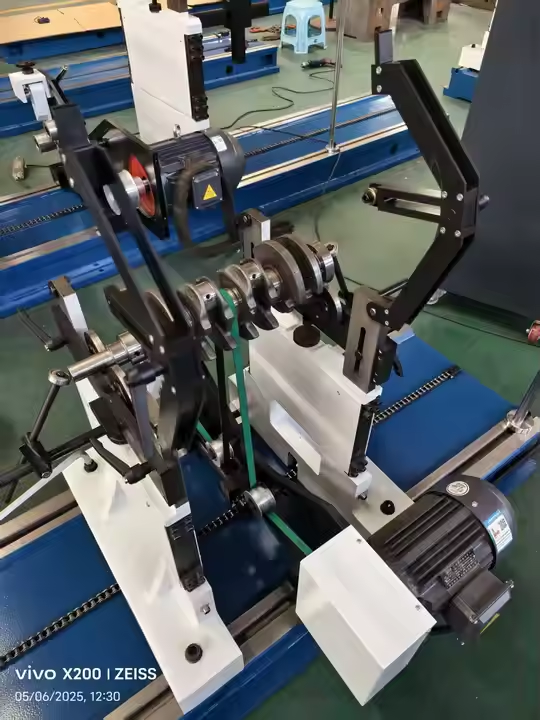

Modern crankshaft balancing machines utilize sophisticated measurement systems that combine laser technology with high-sensitivity sensors. These systems can detect imbalances down to fractions of a gram, ensuring unprecedented accuracy in the balancing process. The integration of digital displays and real-time monitoring capabilities allows operators to track the balancing progress with exceptional precision.

The most advanced machines incorporate multi-plane measurement capabilities, enabling simultaneous analysis of multiple balance points along the crankshaft. This comprehensive approach ensures that both dynamic and static balancing requirements are met, resulting in optimal performance across all operating conditions.

Automation and Control Features

Leading crankshaft balancing machines now feature automated systems that streamline the entire balancing process. These innovations include automatic positioning mechanisms, integrated correction tools, and smart software that guides operators through each step of the procedure. The automation not only increases efficiency but also reduces the possibility of human error during critical measurements.

Control systems have evolved to include intuitive interfaces and programmable parameters that can be saved for different crankshaft models. This versatility allows workshops to handle a wide range of crankshafts while maintaining consistent quality standards across all operations.

Performance Considerations and Specifications

Speed and Capacity Requirements

When evaluating crankshaft balancing machines, speed and capacity specifications play crucial roles in determining their suitability for specific applications. High-end machines can handle crankshafts weighing several hundred kilograms while maintaining precise balance measurements at various operational speeds. The ability to perform measurements at different RPM ranges ensures accuracy across diverse engine applications.

Modern balancing equipment often incorporates variable speed drives that allow for gradual acceleration and deceleration, protecting both the machine and the crankshaft during the balancing process. This feature is particularly important when working with larger or more delicate components.

Accuracy and Repeatability Standards

The highest quality crankshaft balancing machines maintain exceptional accuracy standards, typically achieving repeatability within microns. This precision is achieved through robust construction, advanced calibration systems, and sophisticated software algorithms that compensate for environmental factors.

Industry-leading machines often exceed international standards for balance quality, ensuring that finished components meet or surpass OEM specifications. This level of precision is essential for high-performance engines and critical applications where perfect balance is non-negotiable.

Integration and Connectivity Features

Data Management Systems

Modern crankshaft balancing machines incorporate comprehensive data management capabilities that allow for detailed documentation of all balancing operations. These systems can store thousands of balance programs, measurement results, and correction data, enabling efficient quality control and traceability.

Advanced connectivity features enable integration with factory management systems, allowing for real-time monitoring of machine performance and production metrics. This integration is crucial for maintaining consistent quality standards and optimizing workflow efficiency.

Remote Diagnostics and Support

Leading manufacturers now equip their crankshaft balancing machines with remote diagnostic capabilities, allowing for immediate technical support and troubleshooting. This feature minimizes downtime by enabling rapid identification and resolution of potential issues, often without requiring on-site service visits.

Remote monitoring systems also facilitate predictive maintenance schedules, helping to prevent unexpected breakdowns and ensure consistent machine performance. These capabilities have become increasingly valuable in maintaining efficient operations and reducing maintenance costs.

Investment Considerations and ROI

Cost Analysis Factors

When investing in crankshaft balancing machines, several factors influence the total cost of ownership. Beyond the initial purchase price, considerations include installation requirements, operator training, maintenance schedules, and potential upgrade paths. High-quality machines often command premium prices but deliver superior long-term value through reduced downtime and maintenance costs.

Energy efficiency features, such as regenerative drives and smart power management systems, can significantly impact operating costs over the machine's lifetime. Modern machines often incorporate these technologies to optimize power consumption while maintaining peak performance.

Long-term Value Propositions

The most advanced crankshaft balancing machines offer exceptional durability and upgradeability, protecting the initial investment while allowing for future technological improvements. Manufacturers who prioritize robust construction and modular design ensure that their machines remain viable and competitive for many years.

Support packages and warranty options can significantly enhance the value proposition, providing peace of mind and predictable operating costs. Leading manufacturers often offer comprehensive service agreements that include regular calibration, software updates, and technical support.

Frequently Asked Questions

What are the key maintenance requirements for crankshaft balancing machines?

Regular maintenance typically includes calibration checks, bearing inspections, and software updates. Most modern machines require quarterly calibration verification and annual comprehensive service to maintain optimal performance. Implementing a preventive maintenance schedule can significantly extend equipment life and ensure consistent accuracy.

How does environmental control affect balancing accuracy?

Temperature stability, vibration isolation, and clean air supply are crucial factors affecting balancing accuracy. Modern crankshaft balancing machines often include built-in environmental monitoring systems and compensation algorithms to maintain precision under varying conditions. Proper installation in a controlled environment is essential for optimal performance.

What training is required for operators of advanced balancing equipment?

Operators typically need comprehensive training covering machine operation, software usage, and basic troubleshooting. Most manufacturers provide initial training programs and ongoing support to ensure operators can fully utilize all machine features. Regular skill updates are recommended as technology evolves and new capabilities are added.