The Evolution of Modern Engine Performance Technology

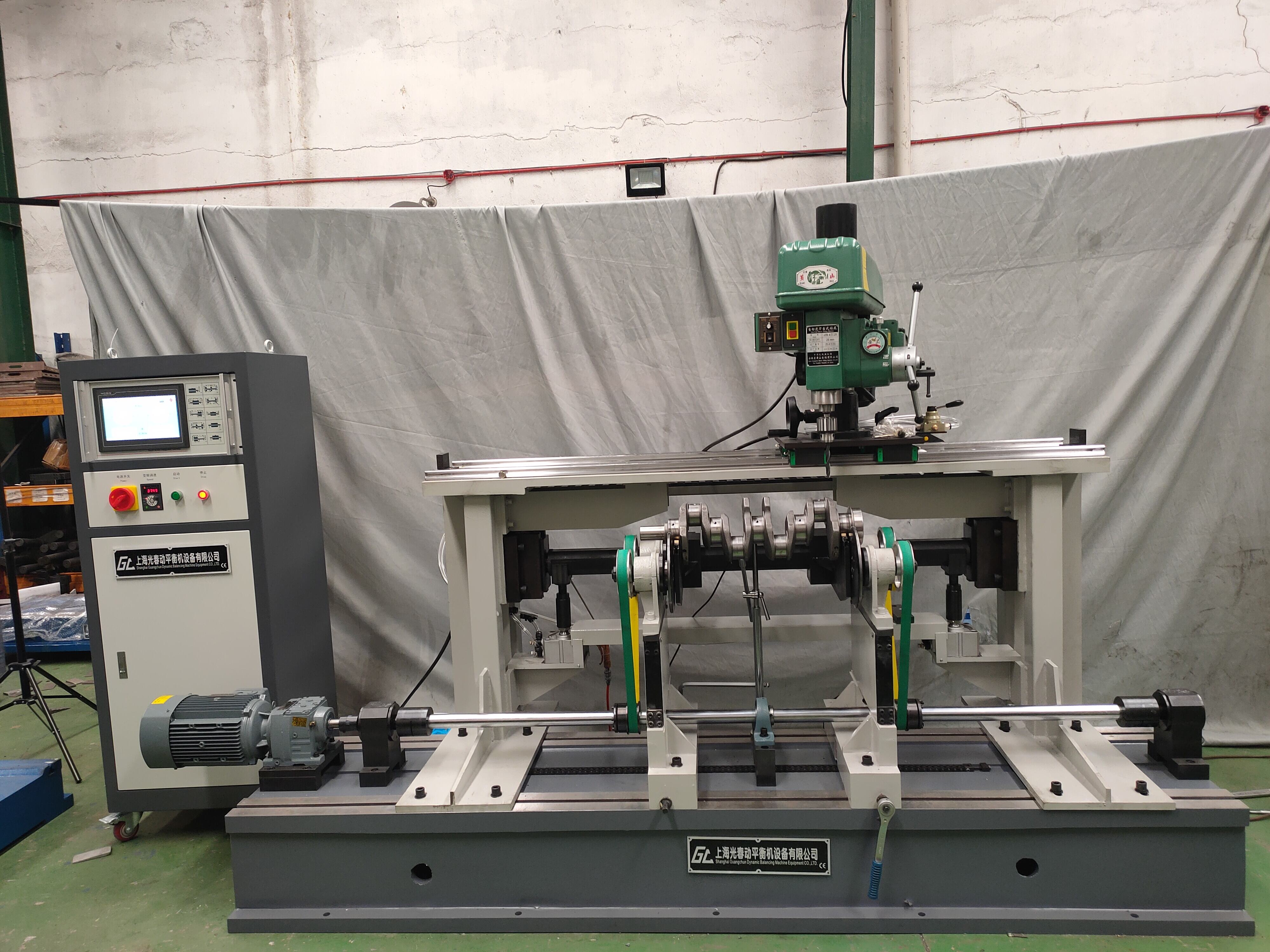

The automotive industry has witnessed remarkable technological advancements over the decades, with crankshaft balancing machines emerging as crucial tools in achieving optimal engine performance and longevity. These sophisticated pieces of equipment have revolutionized how manufacturers and rebuilders approach engine assembly and maintenance, ensuring unprecedented levels of precision in rotating assembly balance.

Modern crankshaft balancing machines represent the culmination of years of engineering innovation, combining advanced sensors, computer-controlled analysis, and precise measurement capabilities. By detecting and correcting even minimal imbalances in engine components, these machines play a vital role in preventing premature wear, reducing vibration, and extending engine life significantly.

Understanding Crankshaft Balance and Its Impact

The Physics Behind Crankshaft Operation

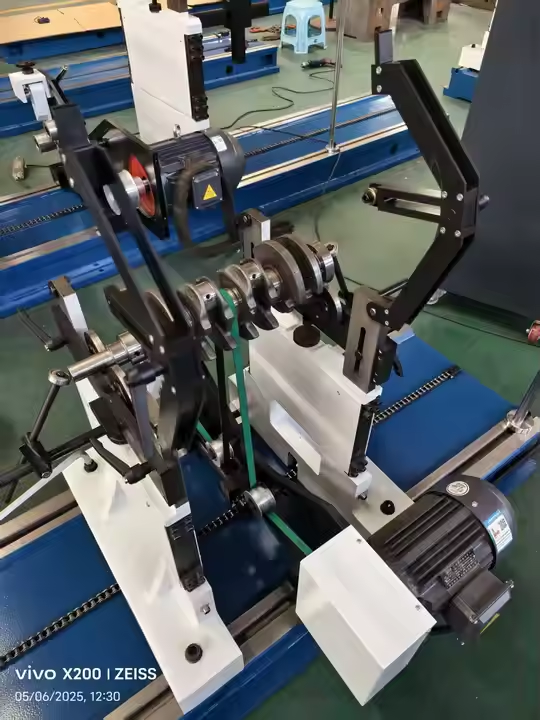

At the heart of every internal combustion engine lies the crankshaft, a complex component that converts linear piston motion into rotational force. When operating at thousands of revolutions per minute, even slight imbalances in the crankshaft assembly can create substantial centrifugal forces. These forces, if left unchecked, generate vibrations that can compromise engine performance and accelerate wear on bearings, seals, and other critical components.

Crankshaft balancing machines utilize sophisticated measuring systems to detect these potential issues before they become problematic. By analyzing the dynamic behavior of the crankshaft during rotation, these machines can identify exactly where corrections are needed to achieve optimal balance.

The Consequences of Imbalanced Crankshafts

An unbalanced crankshaft can lead to a cascade of engine problems, including increased fuel consumption, reduced power output, and accelerated wear on engine bearings. The vibrations created by an imbalanced rotating assembly can transmit through the entire vehicle, affecting everything from transmission components to suspension systems.

Professional engine builders rely on crankshaft balancing machines to prevent these issues, ensuring their builds deliver maximum performance and reliability. The investment in proper balancing equipment pays dividends through extended engine life and improved customer satisfaction.

Advanced Features of Modern Balancing Technology

Digital Precision and Automation

Contemporary crankshaft balancing machines incorporate state-of-the-art digital technology and automated processes. These features enable technicians to achieve balance specifications that would be impossible with older mechanical methods. High-resolution sensors can detect imbalances as small as a fraction of a gram, while computer-controlled systems provide real-time feedback and adjustment recommendations.

The automation capabilities of modern balancing machines have significantly reduced the time required for the balancing process while improving accuracy and repeatability. Technicians can now complete complex balancing operations in a fraction of the time previously required, increasing shop efficiency and throughput.

Integrated Analysis and Reporting

Modern crankshaft balancing machines offer comprehensive analysis tools and detailed reporting capabilities. These systems can generate detailed documentation of the balancing process, including initial measurements, correction points, and final results. This documentation is invaluable for quality control purposes and can serve as a reference for future maintenance or rebuilding work.

The ability to store and analyze balancing data over time allows shops to identify trends and potential issues before they develop into serious problems. This predictive capability helps maintain consistent quality standards and optimize maintenance schedules.

Implementation in Professional Engine Building

Workshop Integration and Setup

Integrating crankshaft balancing machines into a professional engine building operation requires careful consideration of workspace layout and workflow optimization. The machines must be positioned in a location that allows easy access while maintaining protection from dust and vibration that could affect measurement accuracy.

Successful implementation also involves comprehensive training for technicians and establishing standardized procedures for different engine types and specifications. This systematic approach ensures consistent results and maximizes the benefits of the balancing equipment.

Quality Control and Certification

Professional engine builders use crankshaft balancing machines as part of their quality control process, often incorporating balance specifications into their certification procedures. This attention to detail helps distinguish high-quality engine builds from those completed with less rigorous standards.

Many shops now offer detailed balancing reports as part of their documentation package, providing customers with concrete evidence of the attention to detail invested in their engine build. This transparency helps build trust and justify the premium pricing of professional engine work.

Future Trends in Balancing Technology

Integration with Industry 4.0

The next generation of crankshaft balancing machines is expected to feature enhanced connectivity and integration with broader manufacturing systems. These advances will enable real-time data sharing, remote monitoring, and predictive maintenance capabilities, further improving efficiency and quality control.

Industry experts anticipate that future balancing machines will incorporate artificial intelligence and machine learning capabilities, allowing for even more precise measurements and automated adjustment recommendations. These developments will continue to push the boundaries of what's possible in engine building and maintenance.

Environmental Considerations

As sustainability becomes increasingly important in all aspects of manufacturing, newer crankshaft balancing machines are being designed with energy efficiency in mind. Advanced power management systems and more efficient motors help reduce the environmental impact while maintaining or improving performance capabilities.

The focus on environmental responsibility extends to the materials and processes used in balancing operations, with manufacturers developing more sustainable methods for weight addition and removal during the balancing process.

Frequently Asked Questions

What are the primary benefits of using crankshaft balancing machines?

Crankshaft balancing machines provide numerous benefits including reduced engine vibration, extended component life, improved performance, and increased fuel efficiency. They also help prevent premature wear on bearings and other critical engine parts while ensuring smooth operation across all RPM ranges.

How often should crankshaft balancing be performed?

Crankshaft balancing should be performed during initial engine assembly and any time the rotating assembly is modified or rebuilt. For high-performance applications, it's recommended to check balance during major service intervals or when performance changes are noticed.

Can crankshaft balancing improve fuel economy?

Yes, properly balanced crankshafts can contribute to improved fuel economy by reducing mechanical losses and ensuring optimal engine efficiency. A well-balanced rotating assembly requires less energy to operate, allowing more of the engine's power to be used for propulsion rather than overcoming internal resistance.