Modern industrial operations demand precision and reliability across all rotating machinery components. When it comes to maintaining optimal performance in turbocharged systems, turbochargerturbine balancing machines represent the gold standard for ensuring smooth operation and extended component life. These specialized devices have revolutionized how manufacturers and maintenance facilities approach the critical task of balancing turbocharger assemblies, delivering unprecedented accuracy and efficiency in industrial applications.

The automotive and heavy machinery sectors have witnessed remarkable advancements in turbocharger technology over recent decades. As engines become more compact yet powerful, the demands placed on turbocharger components have intensified exponentially. This evolution necessitates sophisticated balancing equipment capable of detecting even the minutest imbalances that could lead to premature failure or reduced performance. Industrial facilities worldwide rely on turbochargerturbine balancing machines to maintain their competitive edge in increasingly demanding markets.

Core Technologies Behind Turbochargerturbine Balancing Systems

Precision Sensor Integration

The foundation of effective turbochargerturbine balancing machines lies in their advanced sensor technology. High-resolution accelerometers and laser displacement sensors work in tandem to detect vibrations as small as 0.01 millimeters per second. These sensors must withstand extreme rotational speeds typical in turbocharger testing environments while maintaining measurement accuracy. The data acquisition systems process thousands of measurements per second, creating detailed vibration profiles that reveal imbalance locations and magnitudes with exceptional precision.

Modern sensor arrays incorporate temperature compensation algorithms to ensure consistent readings across varying environmental conditions. This capability proves essential in industrial settings where ambient temperatures fluctuate throughout production cycles. The integration of wireless sensor networks has further enhanced the flexibility of turbochargerturbine balancing machines, allowing for remote monitoring and real-time data analysis without compromising measurement integrity.

Advanced Control Systems

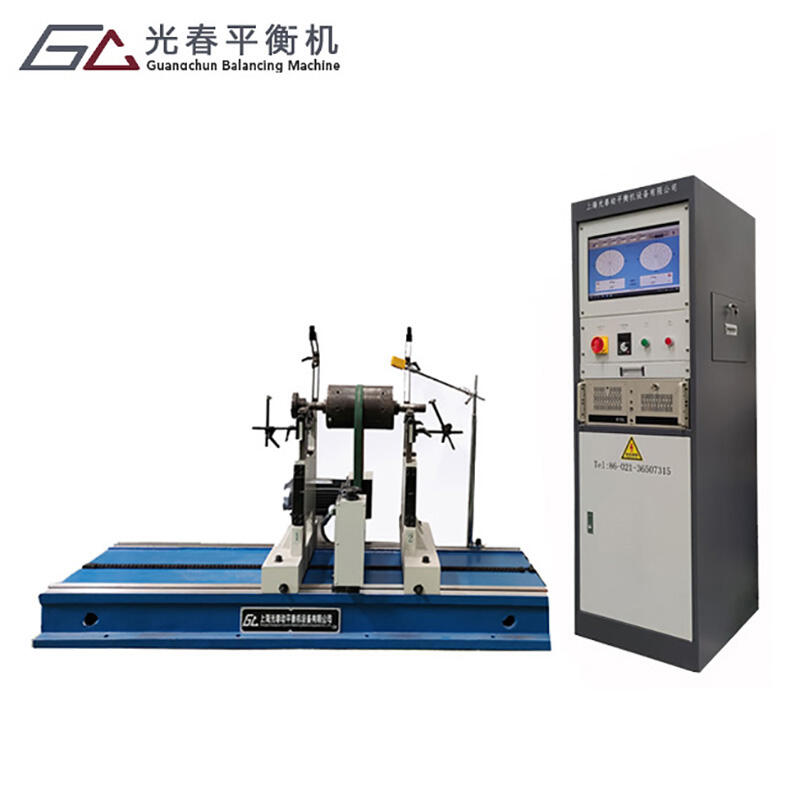

Contemporary turbochargerturbine balancing machines utilize sophisticated microprocessor-based control systems that automate much of the balancing process. These systems employ complex algorithms to calculate optimal correction weights and placement locations, reducing operator skill requirements while improving consistency. The control interfaces feature intuitive touchscreen displays that guide operators through standardized procedures, minimizing the potential for human error during critical balancing operations.

Programmable logic controllers integrated within these systems enable customizable balancing protocols for different turbocharger models and specifications. This adaptability allows facilities to process diverse product lines using a single balancing machine configuration. The control systems also maintain comprehensive data logs for quality assurance and traceability requirements, essential features for ISO certification and regulatory compliance in automotive manufacturing environments.

Industrial Applications Across Manufacturing Sectors

Automotive Manufacturing Integration

Automotive production lines increasingly incorporate turbochargerturbine balancing machines as standard quality control equipment. These machines enable manufacturers to verify turbocharger balance before final assembly, preventing costly warranty claims and ensuring customer satisfaction. The integration with existing manufacturing execution systems allows for seamless data transfer and automated rejection of components that fail to meet stringent balance specifications.

High-volume production environments benefit significantly from the rapid cycle times achievable with modern turbochargerturbine balancing machines. Typical balancing operations complete in under two minutes per component, enabling continuous flow manufacturing without creating bottlenecks. The machines accommodate various turbocharger sizes and configurations through adjustable fixtures and programmable test sequences, maximizing production flexibility while maintaining consistent quality standards.

Remanufacturing and Repair Operations

The remanufacturing sector relies heavily on turbochargerturbine balancing machines to restore used turbochargers to original equipment specifications. These facilities process thousands of units annually, requiring balancing equipment capable of handling components with varying wear patterns and contamination levels. The machines must accurately assess existing imbalances while accounting for material removal during refurbishment processes.

Specialized cleaning protocols integrated within turbochargerturbine balancing machines ensure accurate measurements on previously used components. Ultrasonic cleaning systems remove carbon deposits and oil residues that could affect balance readings, while compressed air systems clear debris from critical measurement surfaces. This comprehensive approach enables remanufacturers to achieve balance tolerances comparable to new production standards, extending component service life and improving reliability.

Performance Benefits and Operational Advantages

Quality Assurance Enhancement

Implementation of turbochargerturbine balancing machines significantly improves quality assurance capabilities across manufacturing operations. Statistical process control features automatically track balance measurements over time, identifying trends that may indicate tooling wear or process drift. This proactive approach prevents quality issues before they impact production, reducing scrap rates and improving overall efficiency.

The precision capabilities of modern turbochargerturbine balancing machines enable detection of imbalances well below levels that would cause noticeable performance degradation. This enhanced sensitivity allows manufacturers to establish tighter quality specifications, resulting in improved product reliability and customer satisfaction. Automated documentation systems generate comprehensive test reports for each component, supporting traceability requirements and facilitating root cause analysis when quality issues arise.

Cost Reduction Through Preventive Maintenance

Regular use of turbochargerturbine balancing machines in maintenance applications generates substantial cost savings through early detection of developing problems. Imbalance conditions that might otherwise go unnoticed until catastrophic failure occurs can be identified and corrected during routine service intervals. This preventive approach extends component life while reducing unplanned downtime and associated repair costs.

The economic benefits extend beyond direct maintenance savings to include improved fuel efficiency and reduced emissions in applications where properly balanced turbochargers operate. Studies demonstrate that maintaining optimal turbocharger balance can improve engine efficiency by up to three percent, translating to significant fuel cost reductions over equipment lifetime. These efficiency gains become particularly valuable in commercial transportation and industrial power generation applications where fuel costs represent major operational expenses.

Selection Criteria for Industrial Applications

Capacity and Size Considerations

Selecting appropriate turbochargerturbine balancing machines requires careful evaluation of production volume requirements and component size ranges. High-capacity facilities processing thousands of units monthly need machines capable of rapid cycle times without sacrificing measurement accuracy. The physical dimensions of turbocharger assemblies must align with machine capacity specifications to ensure proper support and measurement capability across the full product range.

Weight capacity becomes particularly important when processing large turbochargers used in marine, power generation, or heavy industrial applications. These units can weigh several hundred kilograms and require robust balancing machines with appropriate lifting and handling capabilities. Safety considerations mandate that turbochargerturbine balancing machines include proper guarding and emergency stop systems to protect operators from high-speed rotating components during testing operations.

Measurement Accuracy Requirements

Different applications demand varying levels of measurement precision from turbochargerturbine balancing machines. Racing and high-performance automotive applications typically require the tightest tolerances, often specifying residual imbalance levels below 0.5 gram-millimeters. Commercial vehicle applications may accept slightly higher imbalance limits while still maintaining reliability and performance standards.

The measurement resolution capability of turbochargerturbine balancing machines must exceed the required tolerance specifications by sufficient margin to ensure reliable detection of borderline conditions. Industry standards typically recommend measurement systems capable of resolving imbalances at least ten times smaller than acceptance limits. This approach provides adequate margin for measurement uncertainty while ensuring consistent quality outcomes across production batches.

Future Developments in Balancing Technology

Artificial Intelligence Integration

Emerging developments in turbochargerturbine balancing machines incorporate artificial intelligence algorithms to optimize balancing procedures and predict maintenance requirements. Machine learning systems analyze historical balancing data to identify patterns that correlate with component quality and reliability outcomes. This intelligence enables continuous improvement in balancing procedures while reducing the skill requirements for operators.

Predictive analytics capabilities built into advanced turbochargerturbine balancing machines can forecast when balancing equipment itself requires calibration or maintenance. These systems monitor sensor performance, mechanical wear patterns, and environmental factors to schedule maintenance activities before accuracy degradation occurs. The integration of IoT connectivity enables remote monitoring and support, reducing downtime while ensuring consistent measurement capability.

Enhanced Automation Features

Next-generation turbochargerturbine balancing machines feature increased automation to reduce labor requirements and improve consistency. Robotic loading systems automatically position components for testing while vision systems verify proper alignment and orientation. Automated correction weight application systems eliminate manual calculation and placement errors while accelerating the overall balancing process.

Advanced automation extends to data management and reporting functions within turbochargerturbine balancing machines. Integrated systems automatically generate statistical reports, trend analyses, and maintenance recommendations based on accumulated test data. This comprehensive approach transforms balancing operations from simple pass-fail testing to strategic quality improvement tools that drive continuous manufacturing optimization.

FAQ

What maintenance requirements do turbochargerturbine balancing machines typically have

Turbochargerturbine balancing machines require regular calibration verification using certified test weights, typically performed monthly or after a specified number of test cycles. Routine maintenance includes cleaning sensor surfaces, checking drive belt tension, and verifying measurement accuracy against known standards. Most manufacturers recommend annual professional service to ensure optimal performance and measurement reliability.

How do environmental conditions affect turbochargerturbine balancing machine performance

Temperature variations, vibration from nearby equipment, and air currents can impact measurement accuracy in turbochargerturbine balancing machines. Optimal performance requires stable temperature conditions within specified ranges, typically between 18-24 degrees Celsius. Isolation from external vibration sources and protection from air currents help maintain consistent measurement results across different operating conditions.

What training is required for operators of turbochargerturbine balancing machines

Effective operation of turbochargerturbine balancing machines requires understanding of basic vibration principles, safety procedures, and quality control concepts. Most manufacturers provide initial training programs covering machine operation, maintenance procedures, and troubleshooting techniques. Ongoing training ensures operators stay current with software updates and procedural improvements that enhance measurement accuracy and operational efficiency.

Can turbochargerturbine balancing machines handle different turbocharger sizes and types

Modern turbochargerturbine balancing machines feature adjustable fixtures and programmable test parameters to accommodate various turbocharger configurations. Weight capacity ranges from small passenger car units to large industrial applications exceeding several hundred kilograms. Modular fixture systems enable quick changeovers between different component types while maintaining measurement accuracy across the full size range.

Table of Contents

- Core Technologies Behind Turbochargerturbine Balancing Systems

- Industrial Applications Across Manufacturing Sectors

- Performance Benefits and Operational Advantages

- Selection Criteria for Industrial Applications

- Future Developments in Balancing Technology

-

FAQ

- What maintenance requirements do turbochargerturbine balancing machines typically have

- How do environmental conditions affect turbochargerturbine balancing machine performance

- What training is required for operators of turbochargerturbine balancing machines

- Can turbochargerturbine balancing machines handle different turbocharger sizes and types