spindel jævningsmaskine

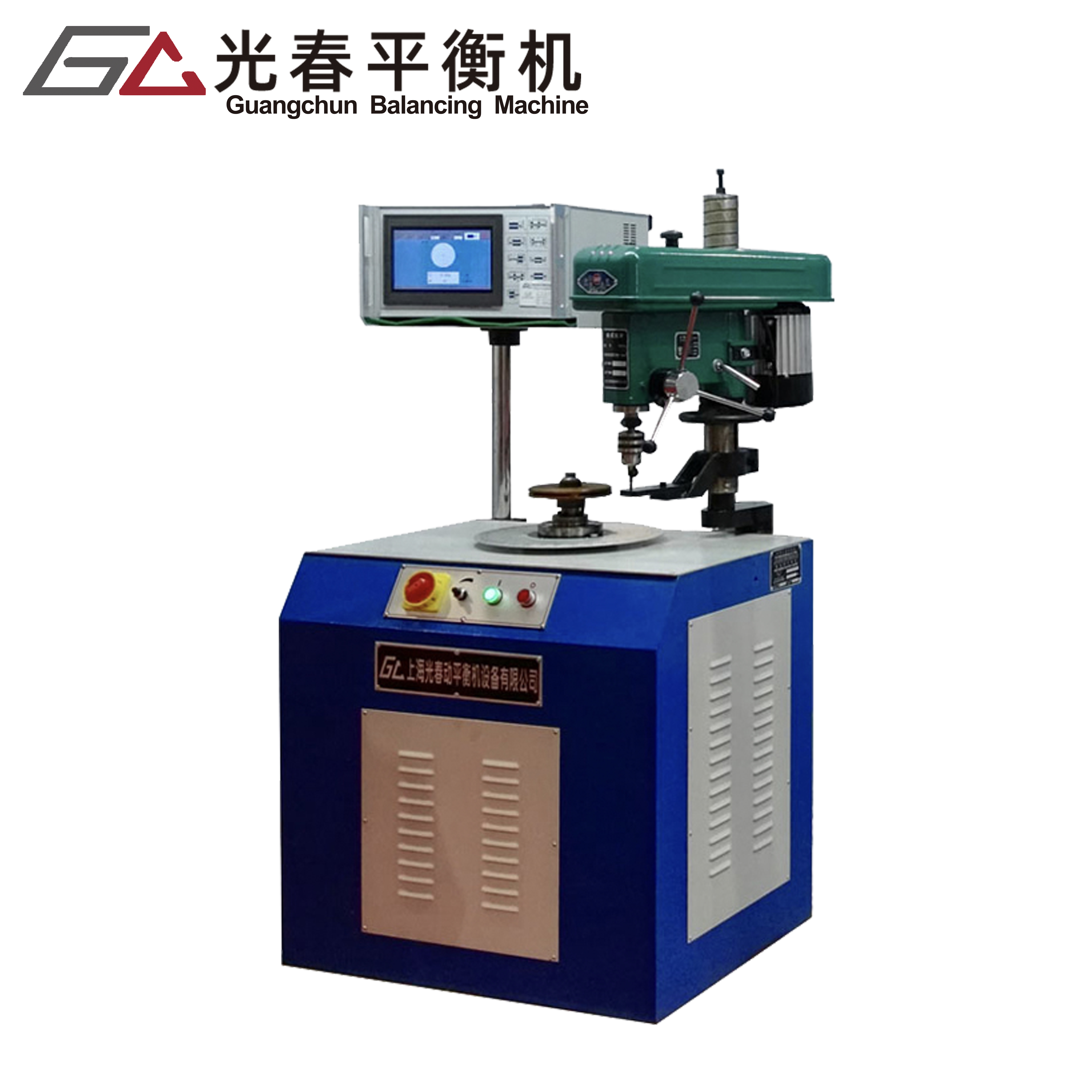

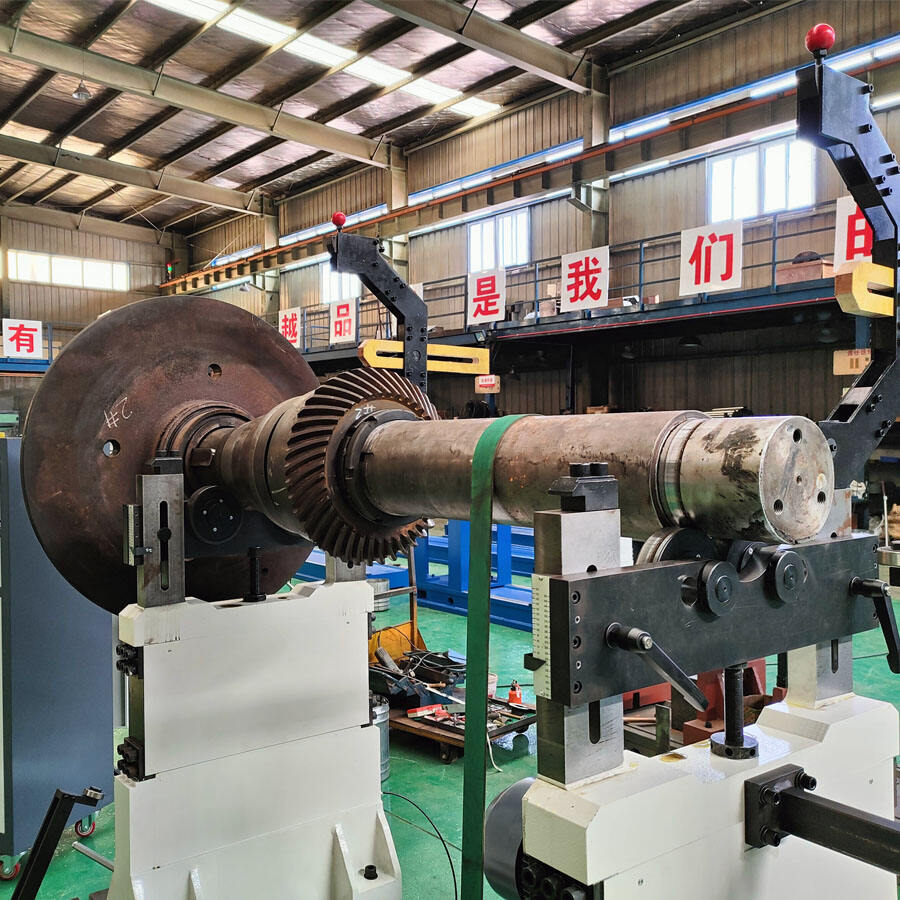

En spindelbalancemaskine er et sofistikeret stykke udstyr, der er designet til at måle og korrigere ujævn vægtfordeling i roterende komponenter, især spindler, der anvendes i forskellige industrielle applikationer. Dette præcisionsinstrument benytter avancerede sensorer og computeriseret analyse til at registrere endog minimale ubalancer, som kunne påvirke maskinens ydeevne. Maskinen fungerer ved at montere spindlen på specialfremstillede understøtninger udstyret med kraftsensorer, som måler vibrationsmønstrene under rotation. Ved hjælp af højpræcisionsmåleteknologi kan den registrere ubalancer så små som 0,001 gram-millimeter, hvilket sikrer optimal ydelse af den balancerede komponent. Maskinens integrerede software behandler de indsamlede data og beregner de nøjagtige steder, hvor korrektionsvægte skal tilføjes eller materiale skal fjernes. Moderne spindelbalancemaskiner har ofte automatiserede målecycler, funktioner til realtidsovervågning og brugervenlige grænseflader, som forenkler balanceringsprocessen. Disse maskiner er afgørende i produktionen, især inden for industrier som luftfart, bilindustri og præcisionsmaskiner, hvor selv mindste ubalancer kan føre til alvorlige problemer. Teknologien omfatter også avancerede funktioner som termisk kompensation og automatisk positioneringssystemer for at sikre præcise målinger under forskellige forhold.