איזון רוטור לייצור חשמל

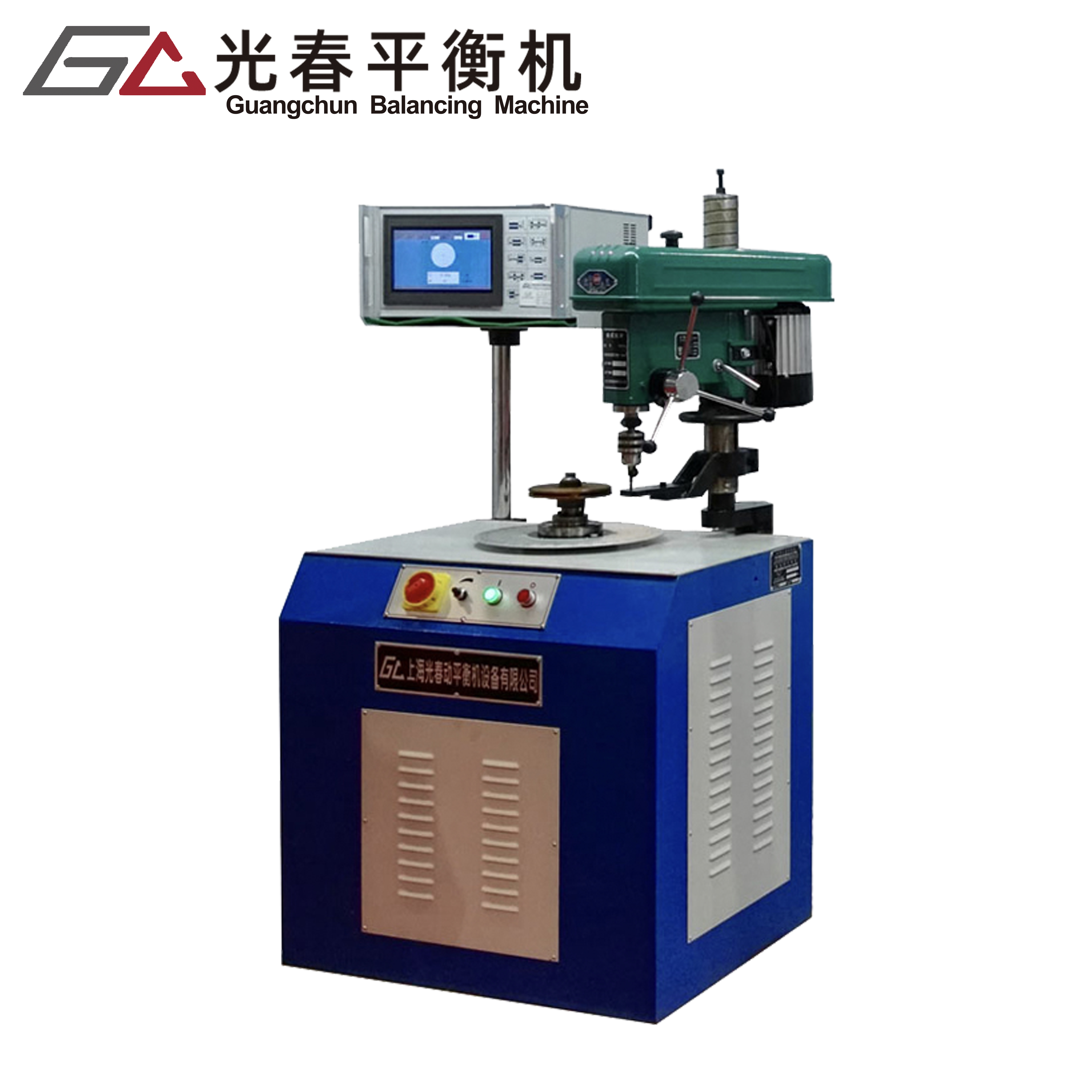

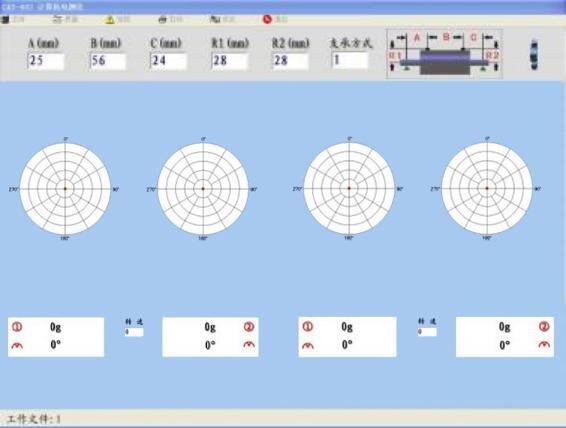

איזון רוטור לייצור חשמל הוא תהליך תחזוקה קריטי המבטיח ביצועים אופטימליים ואריכות טווח של ציוד ייצור החשמל. תהליך ההנדסה המדויק הזה כולל ניתוח ותיקון התפלגות המשקל של רכיבים סובבים בתחנות כוח, גנרטורים ומכשור אחר לייצור חשמל. בתהליך נעשה שימוש בציוד אבחון מתקדם ובתוכנה מתוחכמת לזיהוי אי-איזונים קלים ביותר שעלולים להוביל לרעידות. טכניקות מודרניות של איזון רוטור משתמשות בשתי שיטות: איזון סטטי ואיזון דינמי, причем השיטה השנייה חשובה במיוחד ליישומים במהירות גבוהה בייצור חשמל. הטכנולוגיה כוללת מערכות ניטור בזמן אמת המזוהות אי-איזונים הקטנים כמו חלק ממיליגרם, מה שמגביר את היעילות המקסימלית ומפחית את הנזק לbearings ולרכיבים קריטיים אחרים. בדרך כלל התהליך כולל מדידת רמות רעש, זיהוי מקור וגודל האי-איזון, והשלמת תיקונים מדויקים על ידי הוספת או הסרת משקל. הגישה השיטתית הזו עוזרת בשמירה על ביצועים אופטימליים של הרוטור תחת מגוון מהירויות ותנאי פעולה, מה שמאריך משמעותית את חיי הציוד ומקטין את עלויות התחזוקה. היישום של איזון רוטור משתרע על פני מערכות ייצור חשמל שונות, ביניהן תחנות כוח קיטוריות, תחנות כוח גז, טורבינות רוח ומנועי הידרו-אלקטריות, ולכן מהווה מרכיב חיוני בפעילות ובתחזוקה של תחנות כוח מודרניות.