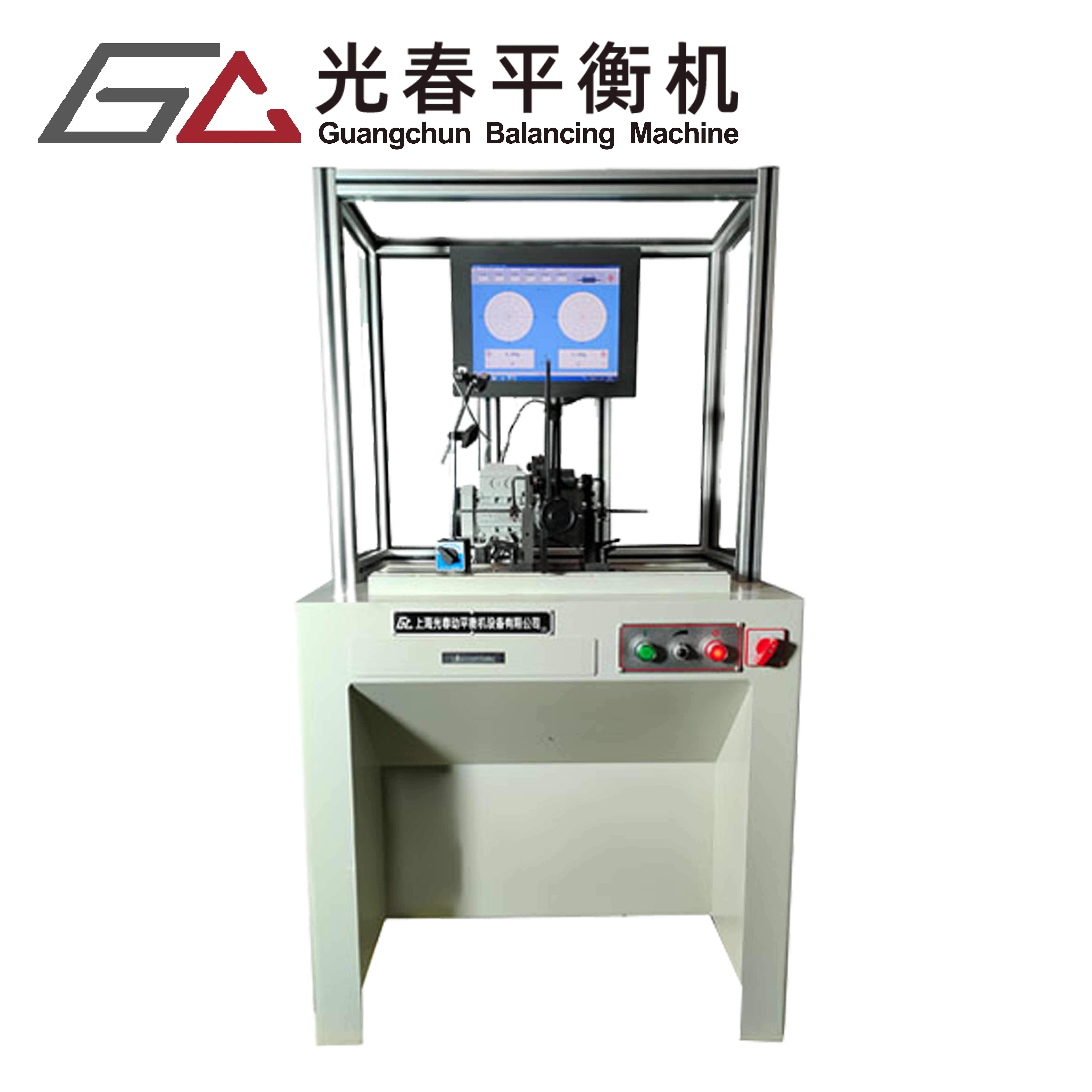

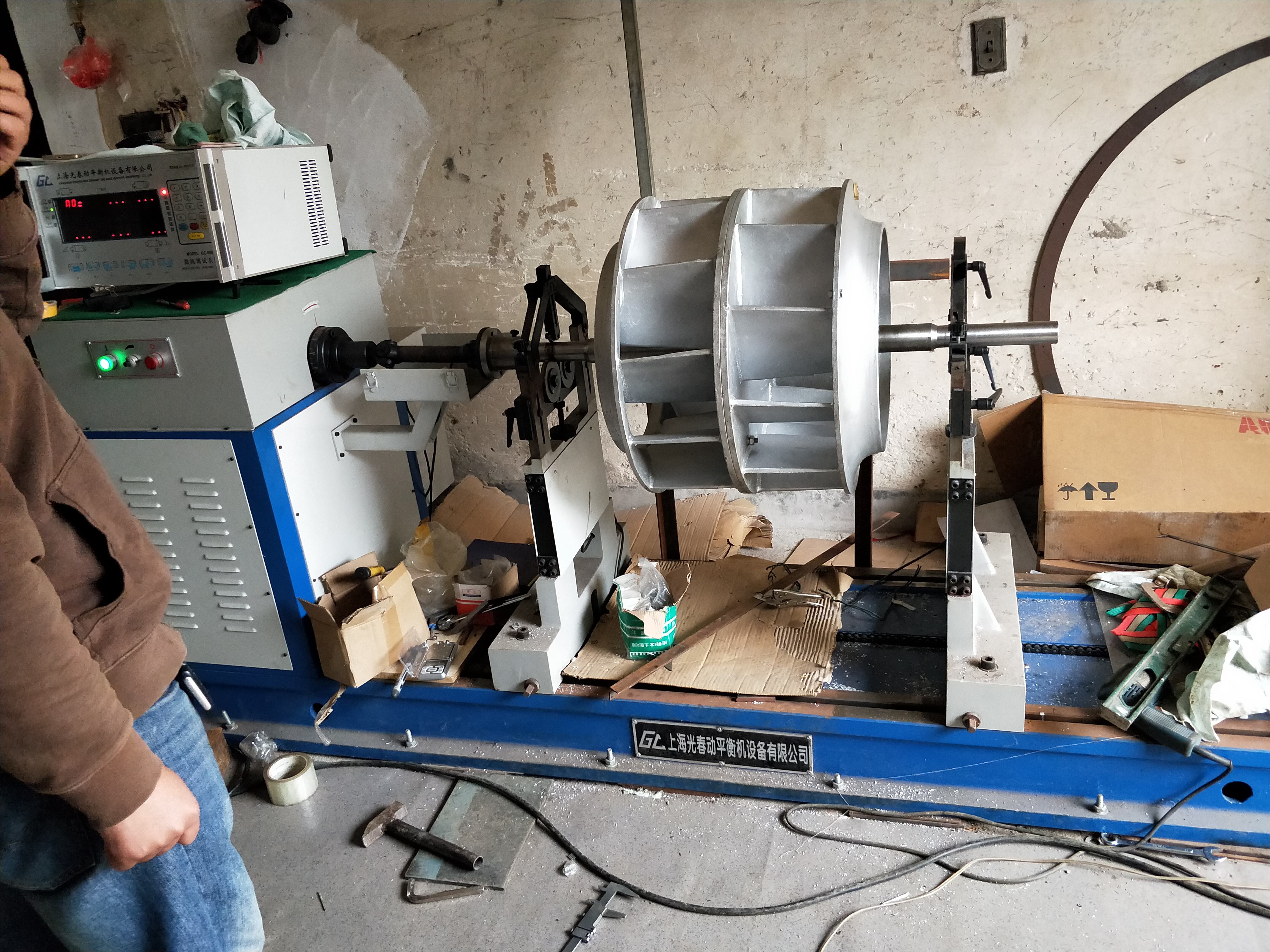

מערכת תיקון אינטליגנטית

מערכת התיקון האינטליגנטית מייצגת קפיצה טכנולוגית בתחום האיזון האוטומטי. המערכת המתקדמת הזו משתמשת במנחות מיקום משקל מדידה המנוהלות באופן מדויק, והיכולות לבצע התאמות זעירות כדי להשיג איזון אופטימלי. תהליך התיקון נעשה בצורה אוטומטית לחלוטין, מה שמבטל את שגיאת האדם ומבטיח תוצאות עקביות לאורך מספר רב של פעולות איזון. האלגוריתמים החכמים של המערכת מחשבים את מספר המינימלי של משקלי תיקון הנדרשים, כדי למקסם את יעילות ואפקטיביות תהליך האיזון. לולאות משוב בזמן אמת מודדות ברציפות את ההשפעה של כל תיקון, וביצוע התאמות עדינות לפי הצורך כדי להשיג ולשמור על איזון מושלם. כמו כן, המערכת מצוידת ביכולות חיזוי המאפשרות לזהות אי-איזונים פוטנציאליים לפני שהם הופכים לבעיה, וכך לאפשר תחזוקה מקדימה והתאמה מראש.