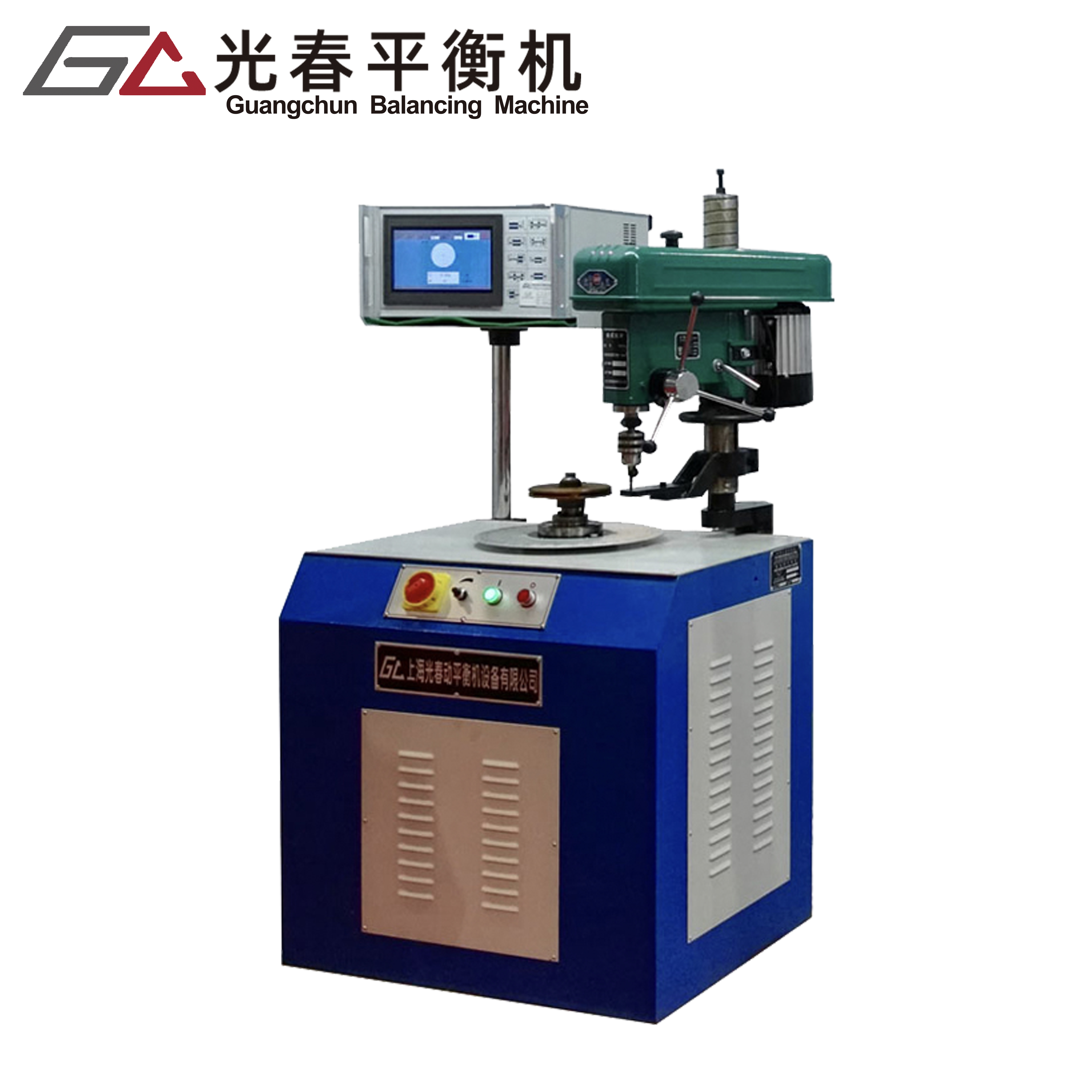

主軸バランス調整機

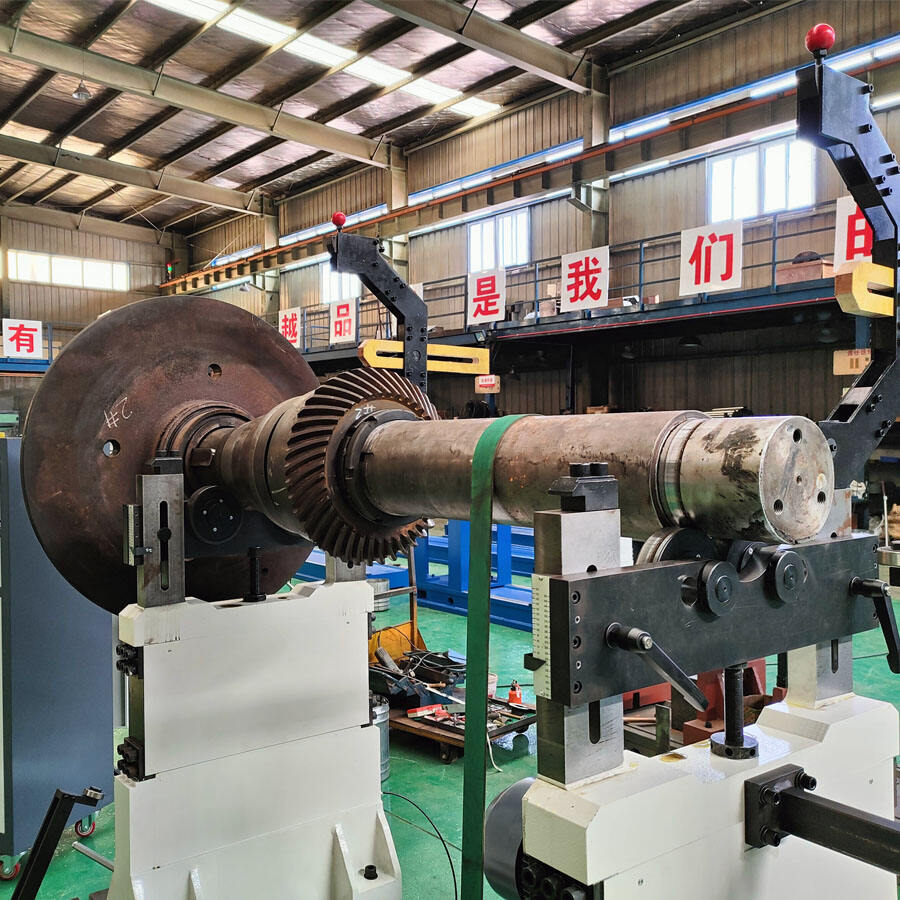

スピンドルバランス機は、さまざまな産業用途で使用される回転部品、特にスピンドルにおける不均等な重量分布を測定および修正するために設計された高度な装置です。この精密機器は、センサーとコンピュータ化された解析技術を用いて、機械の性能に影響を与える可能性のあるごくわずかなアンバランスでさえも検出します。この装置は、専用の支持台にスピンドルを取り付けて動作させ、回転中に発生する振動パターンを測定する力センサーを使用してアンバランスを検知します。高精度の測定技術により、0.001グラムミリメートルという非常に小さなアンバランスまで検出可能であり、バランス調整後の部品が最適な性能を発揮できるようにしています。内蔵されたソフトウェアが収集したデータを処理し、補正用の重りを追加すべき正確な位置や除去すべき素材部分を算出します。最新のスピンドルバランス機には、自動測定サイクル、リアルタイムモニタリング機能、操作性の高いインターフェースが搭載されており、バランス作業を簡素化しています。このような装置は、航空宇宙、自動車、高精度加工などの製造業において不可欠であり、ほんのわずかなアンバランスでも重大な問題を引き起こす可能性があります。また、この技術には、熱変位への補償機能や自動ポジショニングシステムなど、さまざまな条件下で正確な測定を行うための高度な機能も備わっています。