ნავის ბურღის გაწონასწორება

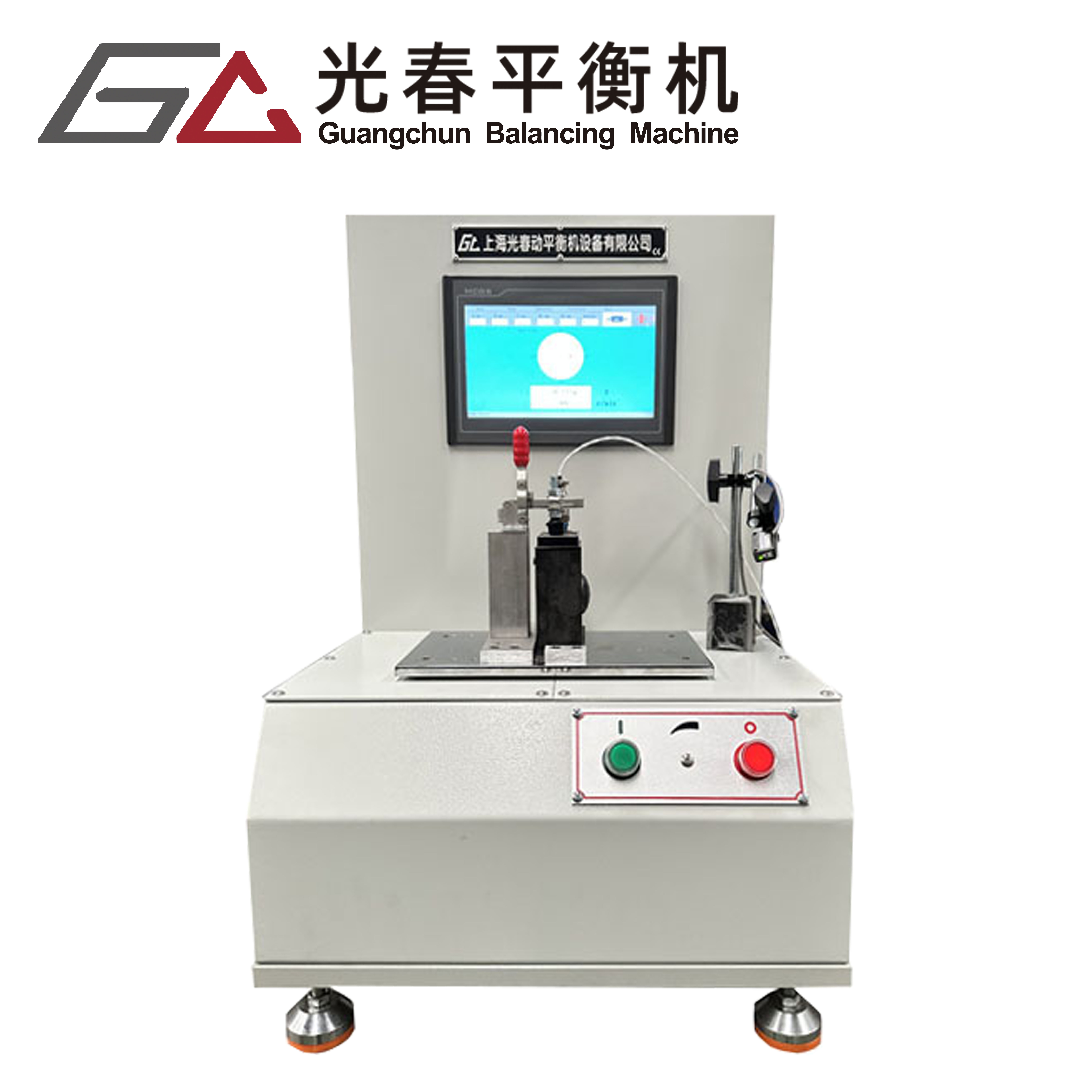

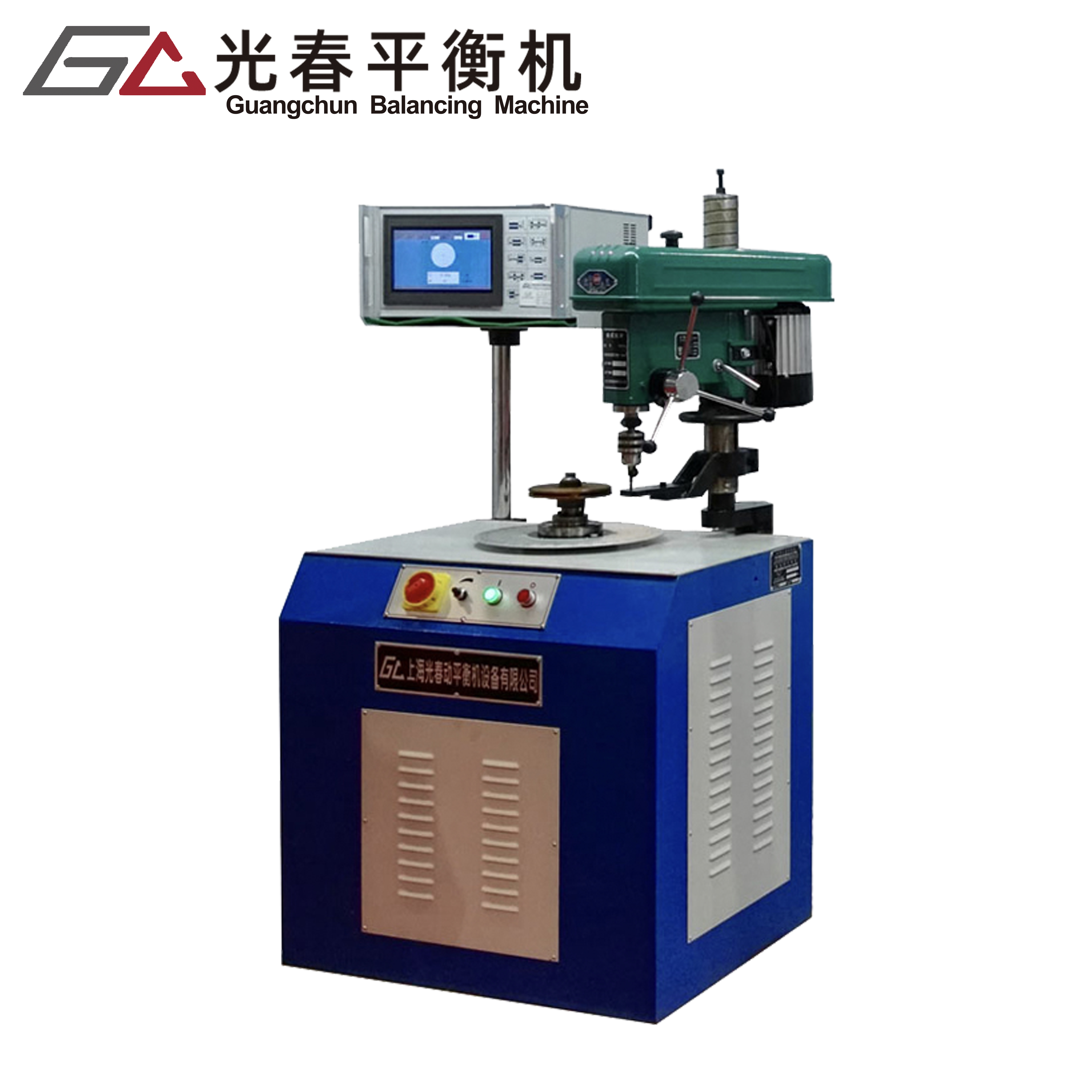

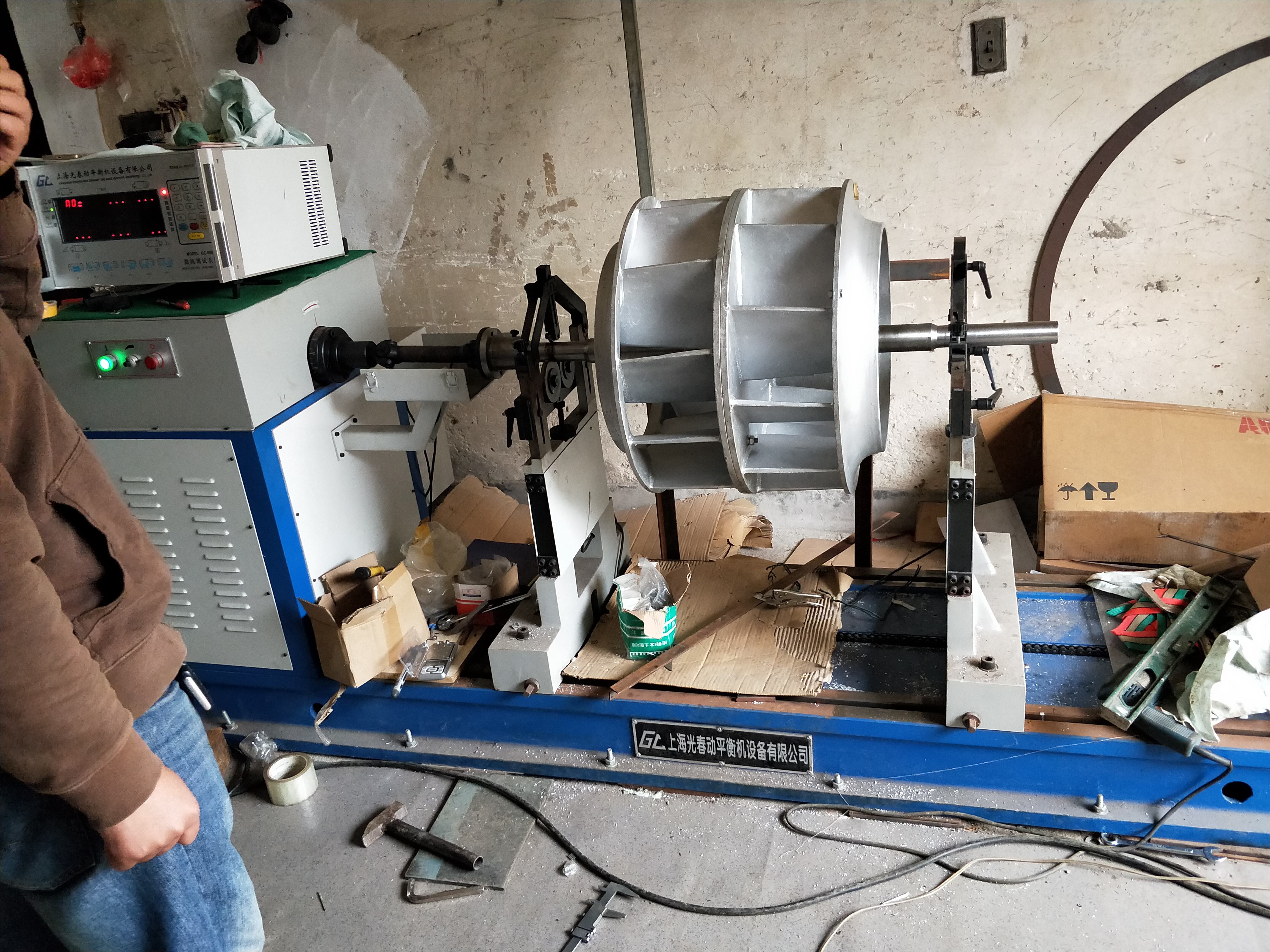

Ნავის პროპელერის ბალანსირება მნიშვნელოვანი მომსახურების პროცედურაა, რათა უზრუნველყოთ საზღვაო სატრანსპორტო საშუალებების მაქსიმალური წარმოებითობა და გრძელვადიანობა. ზუსტი პროცესი მოიცავს პროპელერებში წონის განაწილების არასაჭირო გადახრების ანალიზს და კორექციას, რათა ამოიღოს ვიბრაცია და გააუმჯობესოს საერთო ეფექტურობა. ახალგაზრდა ბალანსირების ტექნიკა იყენებს საუკეთესო ელექტრონულ მოწყობილობებს წონის გადახრების ზომვისთვის უნციის წილადებამდე, რათა უზრუნველყოთ სრული ბრუნვითი ჰარმონია. პროცედურა იწყება პროპელერის სპეციალურ ბალანსირების მანქანაზე დამაგრებით, რომელიც ბრუნავს სხვადასხვა სიჩქარით წონის განსხვავებების გასარკვევად. შემდეგ ტექნიკოსები სტრატეგიულად ამატებენ ან ამოიღებენ მასალას კონკრეტული ადგილებიდან სრული წონასწორობის მისაღებად. ეს მეცნიერული მიდგომა განიხილავს როგორც სტატიკურ ბალანსს, როდესაც პროპელერი უძრავია, ასევე დინამიურ ბალანსს, როდესაც ის ბრუნავს. სწორი ბალანსირება მნიშვნელოვნად ამცირებს ძრავის, გადაცემათა და ვალის კომპონენტების მოხსნას, ამაღლებს საწვავის ეფექტურობას და ნავის მართვას. პროცედურა ასევე გადაწყვეტს პროპელერის დაზიანების, შეკეთების ან მოდიფიკაციის შედეგად წარმოქმნილ პრობლემებს, რათა უზრუნველყოთ პროპელერის დამახასიათებელი მახასიათებლების შენარჩუნება. პროფესიონალური ბალანსირების მომსახურება ჩვეულებრივ მოიცავს დაზიანების სრულ ინსპექციას, ბიჯისა და კოვზის ზუსტ გაზომვას და ბალანსირების პროცესის დეტალურ დოკუმენტაციას.