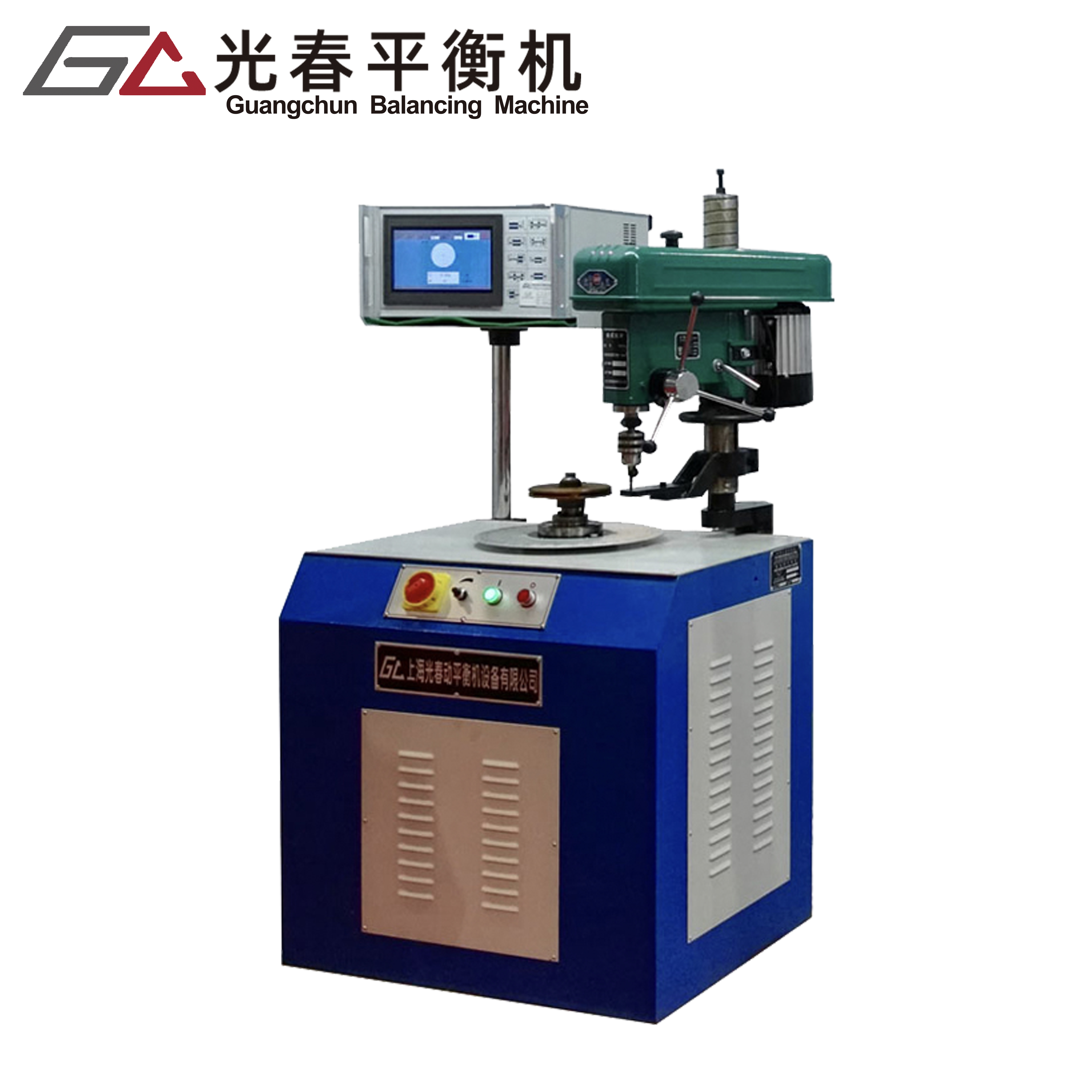

spindel muvazenasi mashinasi

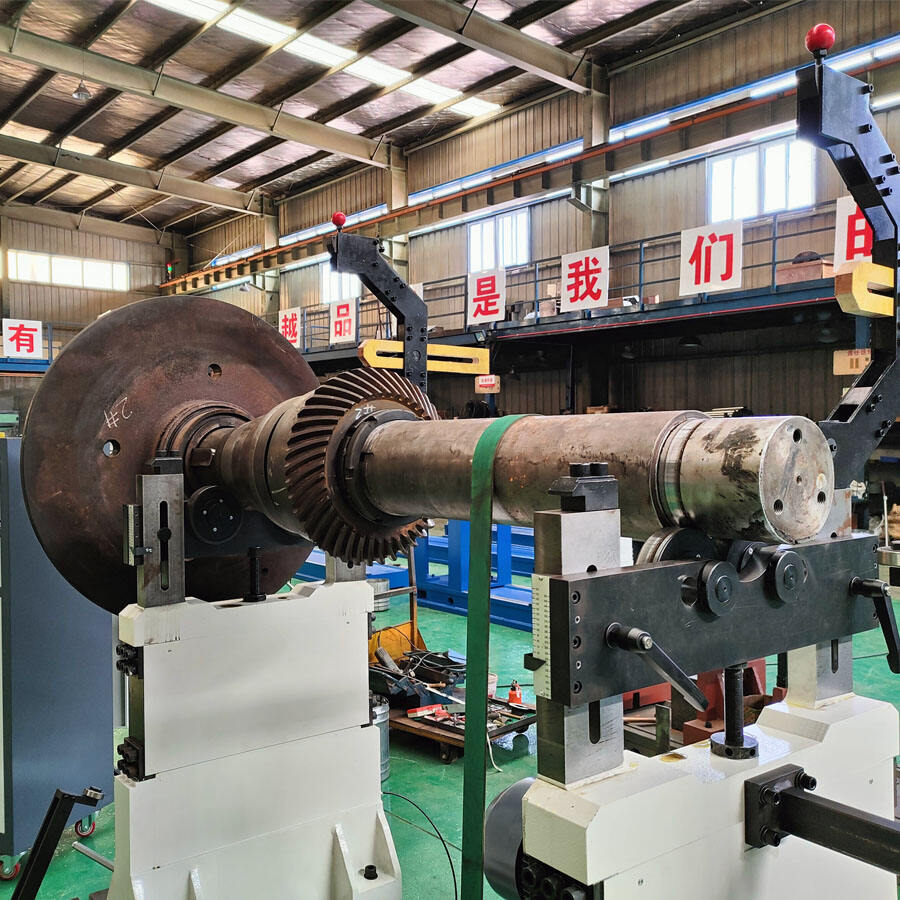

Val balanslash mashinasi - turli sanoat sohalarida ishlatilayotgan val komponentlaridagi noaniq vazn taqsimotini o'lchash va tuzatish uchun mo'ljallangan murakkab jihozdir. Ushbu aniqlik asbobi aylanish jarayonida vujudga keladigan tebranishlarni kuzatuvchi sensorlar yordamida o'rnatiladi. Baland aniqlikdagi o'lchov texnologiyasi yordamida 0,001 gramm-millimetrdan boshlab eng maydaroq noaniqliklarni ham aniqlash imkonini beradi. Dasturiy ta'minoti tomonidan olingan ma'lumotlar qayta ishlanadi hamda tuzatish uchun kerak bo'lgan og'irliklarning aniq joylashish holati hisoblab topiladi. Hozirgi zamonaviy val balanslash mashinalarida avtomatik o'lchash sikllari, haqiqiy vaqt rejimida nazorat qilish imkoniyati hamda foydalanuvchiga qulay interfeyslar mavjud. Bu turdagi mashinalar ayniqsa aviatsiya, avtomobil va yuqori aniqlikdagi sanoat sohasida keng qo'llaniladi. Shuningdek, har xil sharoitlarda ham aniqlikni saqlash uchun termal kompensatsiya hamda avtomatik pozitsionlash sistemalari bilan jihozlangan.