balancing machine thing

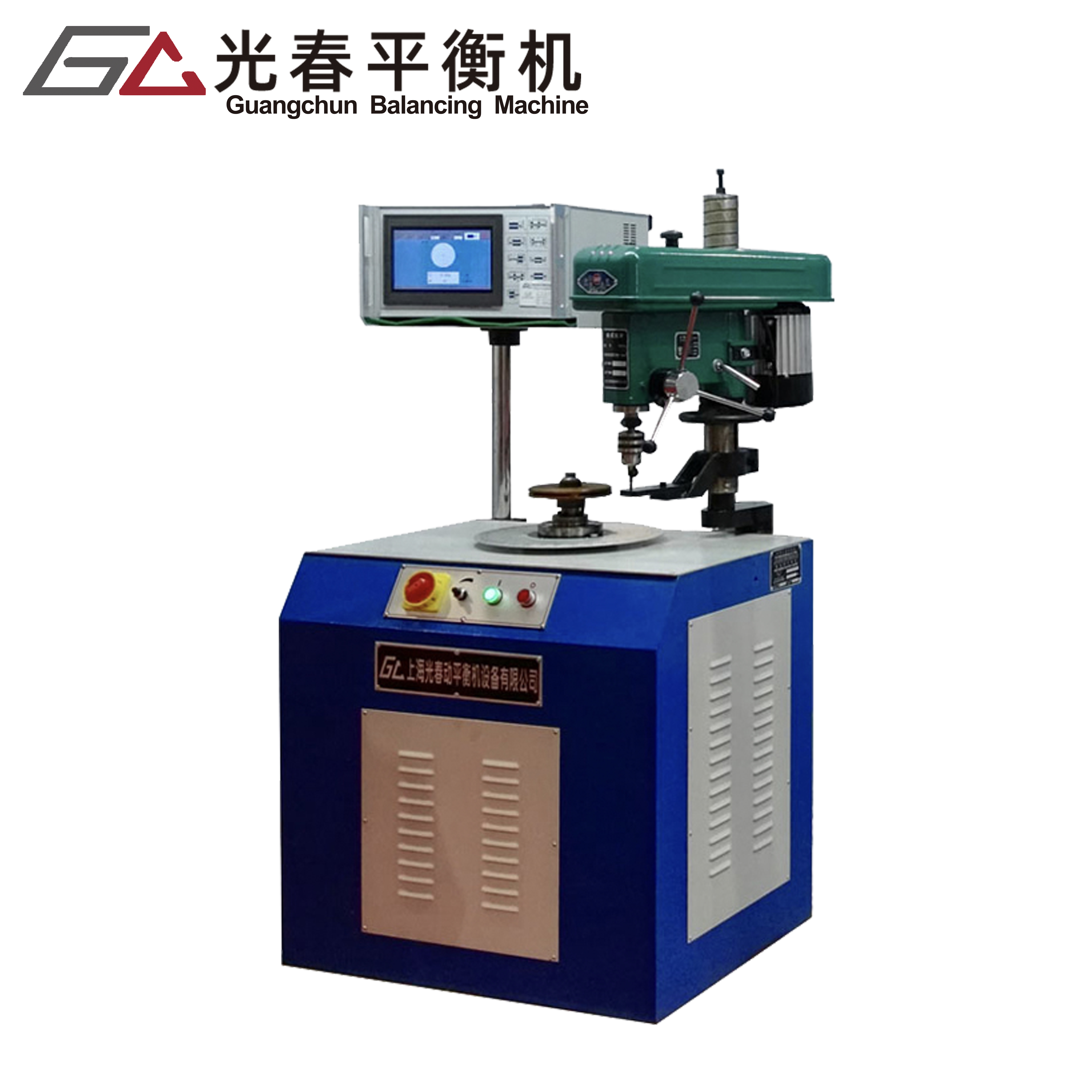

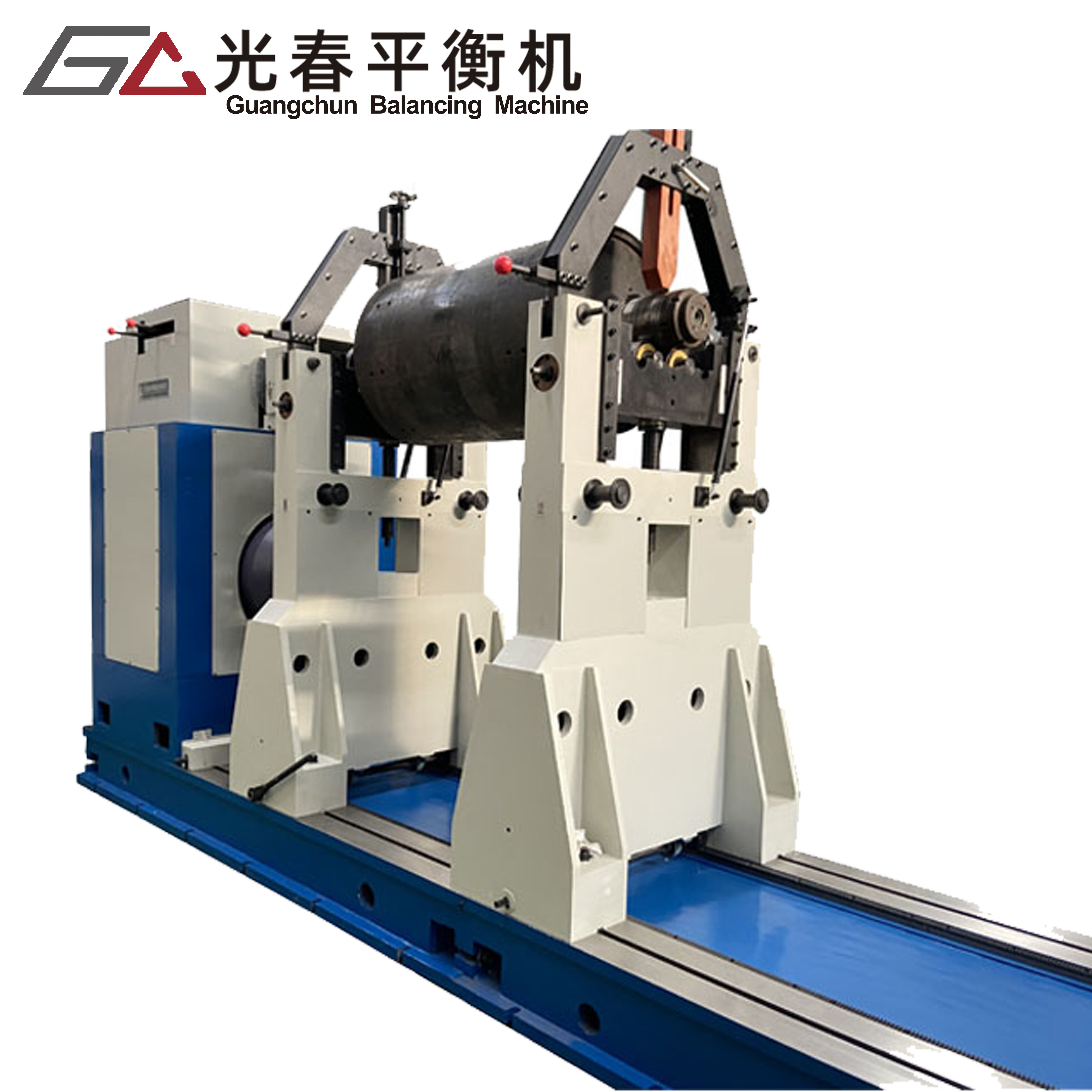

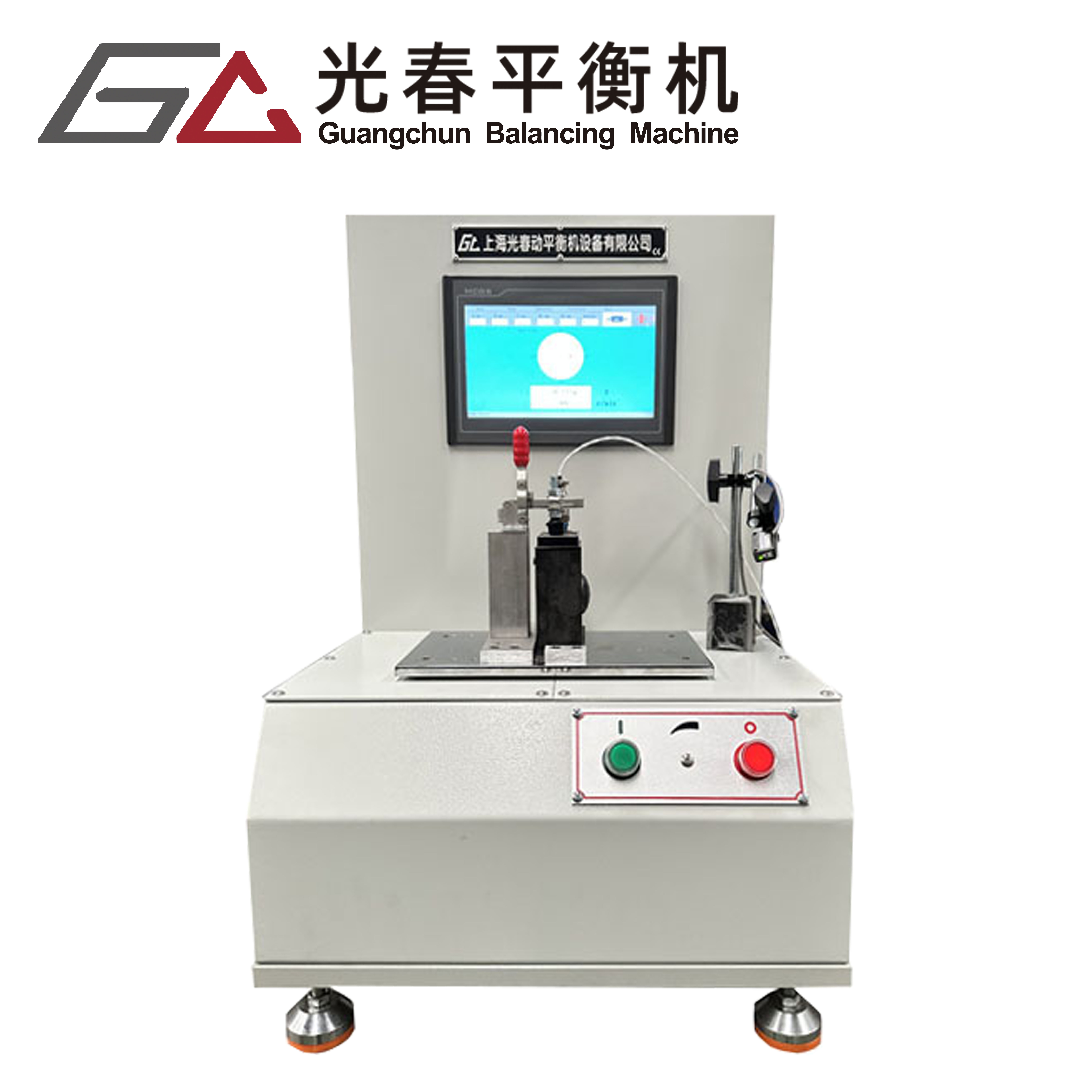

A balancing machine is a precision engineering instrument designed to detect and measure imbalance in rotating components. This sophisticated device operates by spinning the test piece at specific speeds while utilizing sensitive sensors to detect any vibration or movement that indicates imbalance. The machine combines advanced electronic measurement systems with mechanical components to provide accurate readings of both the amount and location of imbalance. Modern balancing machines incorporate digital technology, offering real-time data analysis and automated correction suggestions. They can handle various component sizes, from small turbine blades to large industrial rotors, with some machines capable of managing weights up to several tons. The technology employs both static and dynamic balancing principles, ensuring comprehensive analysis of rotating parts. These machines are equipped with user-friendly interfaces, allowing operators to input specifications and receive detailed reports. The process typically involves mounting the component, running multiple test cycles, and making precise adjustments based on the machine's calculations. Advanced features include automatic positioning systems, thermal compensation, and calibration verification protocols.