dynamic balancing

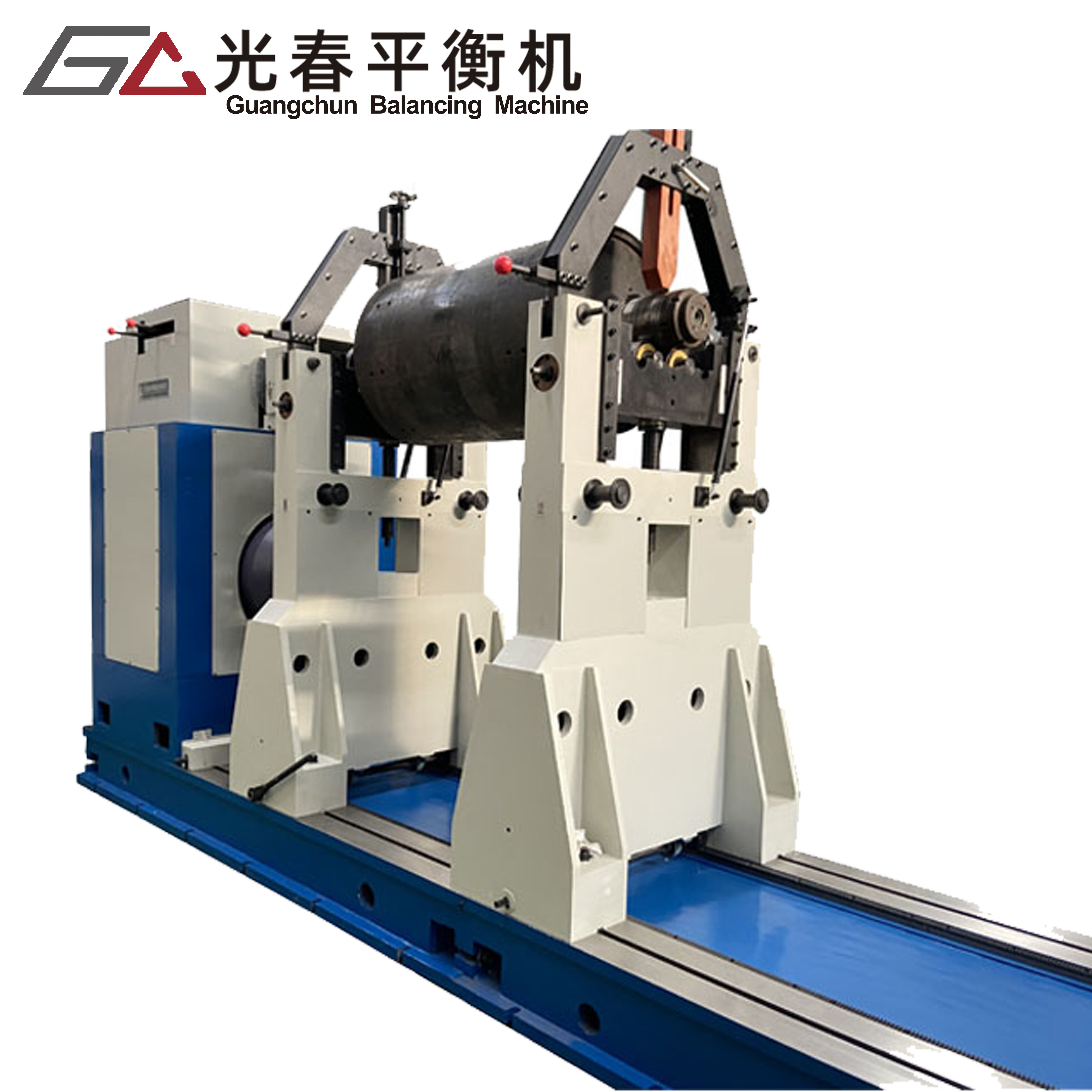

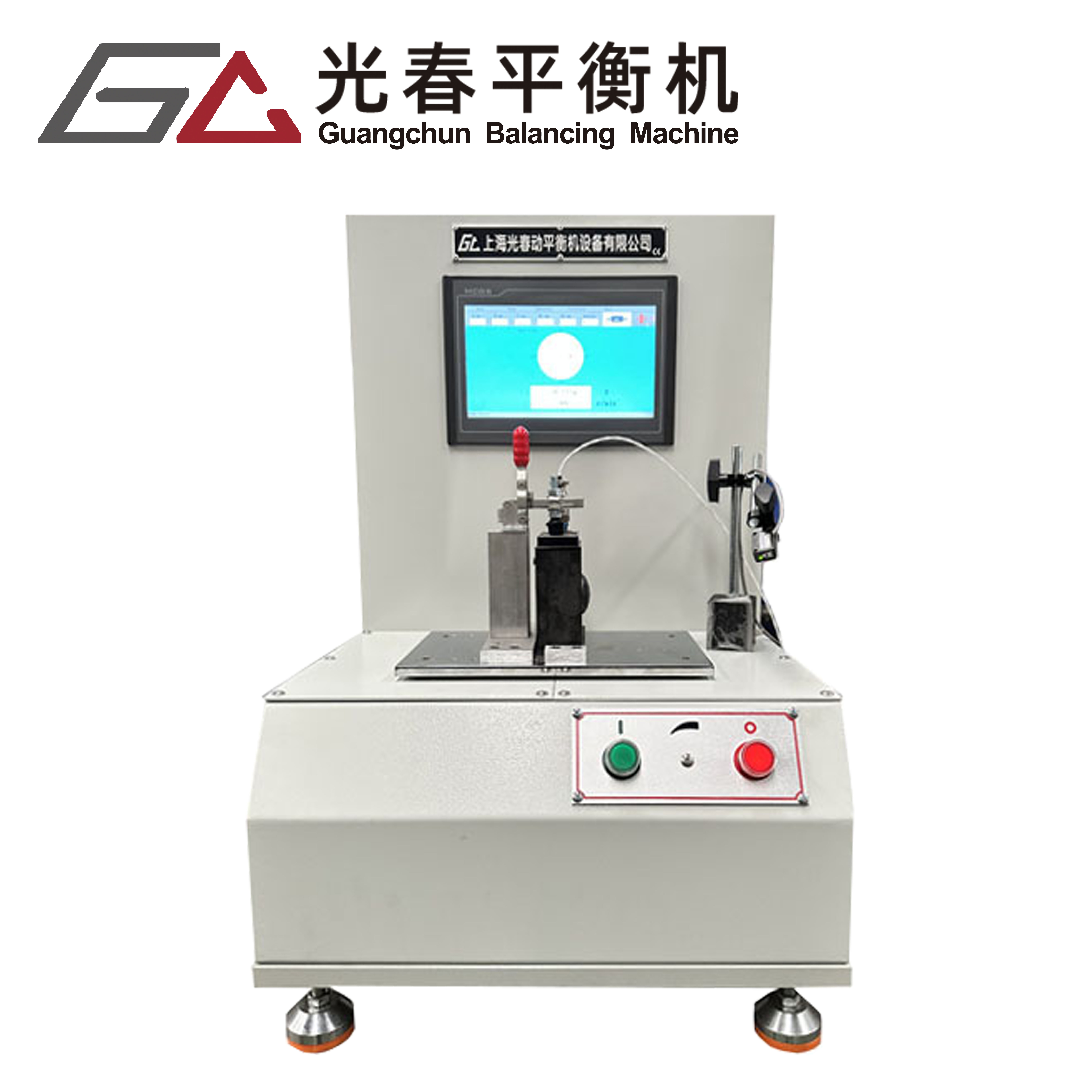

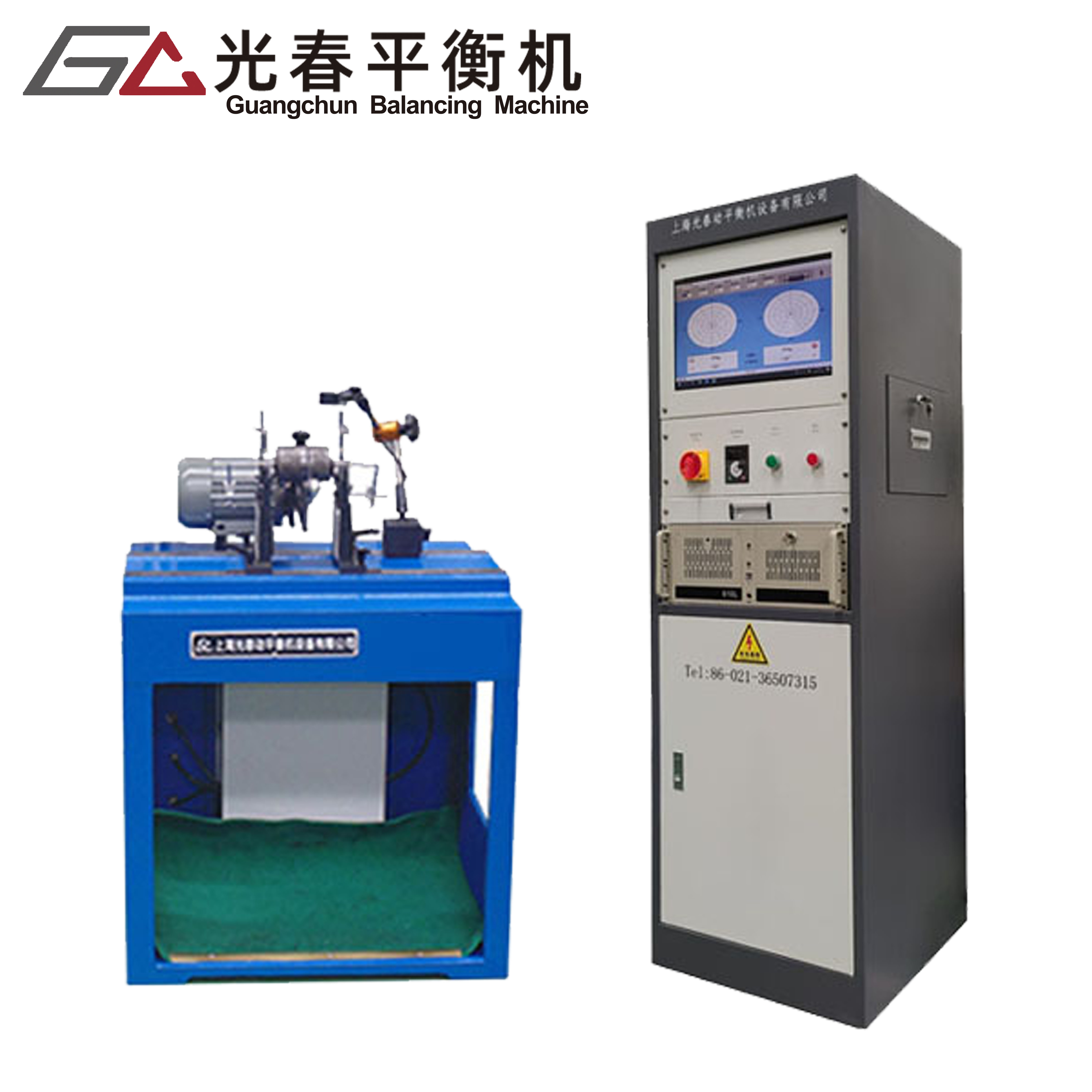

Dynamic balancing is a critical process in rotating machinery maintenance and optimization that ensures smooth, efficient operation of rotating components. This sophisticated technique involves the measurement and correction of mass distribution in rotating parts to eliminate unwanted vibrations and forces. The process utilizes advanced sensors and computerized analysis to detect imbalances at various speeds, making it essential for high-speed machinery. Modern dynamic balancing systems incorporate real-time monitoring capabilities, allowing for continuous assessment and adjustment of rotating components during operation. The technology applies to a wide range of applications, from industrial turbines and electric motors to automotive crankshafts and aircraft engines. The process typically involves mounting the component on a specialized balancing machine that can rotate it at specific speeds while measuring vibration levels and phase angles. Advanced software then calculates the exact locations where weight needs to be added or removed to achieve optimal balance. This technology has evolved to include portable balancing equipment for field service, making it possible to perform precise balancing operations on-site without dismantling entire systems.