driveline balancer

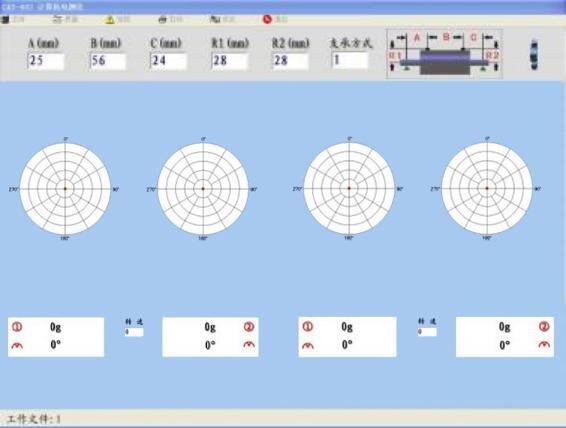

A driveline balancer is an essential diagnostic and maintenance tool designed to identify and correct imbalances in vehicle driveshafts, propeller shafts, and other rotating components. This sophisticated equipment utilizes advanced sensor technology to measure vibration levels and pinpoint exact locations of imbalance with exceptional accuracy. Operating through high-precision electronic measurements, the driveline balancer can detect irregularities at various speeds and loads, ensuring comprehensive analysis of the entire driveline system. The device incorporates digital processing capabilities to analyze complex vibration patterns and provide real-time feedback for precision balancing adjustments. Modern driveline balancers feature user-friendly interfaces that display detailed diagnostic information, allowing technicians to quickly identify issues and implement corrective measures. These machines are particularly valuable in automotive repair shops, truck maintenance facilities, and industrial settings where maintaining optimal driveline performance is crucial for vehicle operation and safety. The technology enables both static and dynamic balancing procedures, ensuring complete coverage of all potential imbalance scenarios. With capabilities to handle various driveshaft sizes and configurations, these machines have become indispensable tools in professional vehicle maintenance.